When looking for trustworthy piping parts for Armenia's industrial projects, Chinese blind flange exporters have become the go-to people for buyers around the world. These specialized parts stop fluids or gases from flowing through pipelines, either temporarily or permanently. They are very important for disconnecting sections of the pipeline to do maintenance, repairs, or changes to the system. As Armenia's industry grows, it needs reliable vendors who can deliver certified blind flanges that meet global standards at a good price and with quick delivery times. Chinese manufacturers do this best by combining advanced production capabilities with comprehensive quality control systems, which ensure that projects succeed in a wide range of industries.

Understanding Blind Flanges in Industrial Applications

Industrial piping systems use a variety of connection methods to make sure the system stays in one piece and the pipes don't leak. Of these parts, blind flanges have a special purpose that makes them impossible to live without in many areas. Understanding their role and specifications helps procurement teams make good decisions that are in line with the needs of the project.

What is a blind flange? What do you need to know about it?

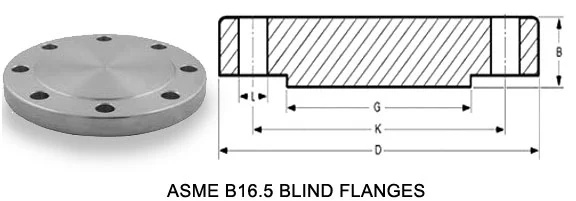

A blind flange is a round plate made of metal that covers the end of a pipe so that no gas or liquid can get through the pipe's connection point. Unlike other types of flanges, blind flanges block piping systems so that nothing can get through. There are holes for bolts all the way around these parts so that they can be lined up with the flanges on the pipes. This means that normal gaskets and bolts can be used to make sure that they are safely installed.

Different methods are used to make these flanges based on their intended use. For normal industrial use, versions made of carbon steel are very strong. In tough conditions, versions made of stainless steel are better at resisting rust. When temperatures or pressures get very high or very low, alloy steels work better. Choosing the right material is an important part of the procurement process because it changes the flange's ability to work with different chemicals, the temperatures it can handle, and its pressure rating.

Advantages of Using Blind Flanges in Projects

These sealing parts have many benefits that help industrial piping systems work better, so they are very helpful for that purpose. Their design makes it easy to get to for maintenance without making changes to the pipeline infrastructure that can't be undone. Blind flanges are easy to remove to restore normal flow and seal reliably when temporary isolation needs to be in place.

The installation process is easier than methods that permanently seal things together, like welding, and only needs a little bit of special equipment. This level of accessibility makes it easier to keep the system up and running, and it can be used during planned shutdowns, which helps save money. Also, their standard size means they will work with flange connections that are already there, so most of the time, no custom changes have to be made. Being able to pick different face types and pressure classes makes it possible to meet the system's needs exactly.

How to Select the Right Blind Flange Supplier for Armenia Projects?

Proper procurement starts with supplier analysis. This ensures quality products, on-time deliveries, and 24/7 support. Industrial projects are complicated, so partners must know the technical details and be able to communicate during procurement.

Important Supplier Selection Considerations

Quality certifications are the easiest way to choose a supplier. API and ASME certifications demonstrate that ISO 9001:2015-compliant quality management is possible. Suppliers should provide material test certificates (MTCs) and third-party inspection reports showing part size and functionality.

Production method affects quality and delivery time. Modern machining tools ensure consistent sizes and surface finishes in factories. Material chemicals and mechanics are checked by quality control labs to ensure they meet standards for how they work and what they are made of. Suppliers who test their products themselves are faster and more reliable.

Experience trading with other countries is helpful. Experienced exporters know that each country has different customs, shipping, and paperwork rules. They've done similar projects, so they know what could go wrong and how to fix it. Knowing many languages and being in different time zones simplifies project work and technical discussions.

How to Use Blind Flanges in Your Project?

The technical specifications must match system parameters to work properly and safely. Working pressure is limited by pressure class ratings. Class numbers 150, 300, and 600 are common. Higher numbers indicate higher quality for specialized uses. Different materials can safely withstand heat, cold, and pressure. Temperature ratings show this.

Different countries have different size rules. In North America, ASME B16.5 is popular, but in Europe, EN is. Flat face (FF), ring-type joint (RTJ), and raised face affect gasket selection and sealing. Knowing the surface finish requirements helps you choose a leak-proof gasket.

Comparison of Blind Flanges and Alternative Solutions

Understanding how different sealing methods work helps procurement teams choose the best options for different uses. Each choice has its own pros and cons that impact the cost up front and the performance over time.

Blind Flange and Weld Neck and Threaded Flanges: Which One is Best for Your Project?

Weld neck flanges make the structure very strong through welded connections, but in some cases, they need skilled welders and heat treatment after welding. Their permanent installation makes it hard to change things in the future, unlike blind flanges that can be removed. Weld neck flanges work best when there is a lot of pressure, but blind flanges are better for maintenance and making changes to the system because they are more flexible.

Flanges with threads let you install them without welding, but they might come loose if they get hot and cold or if they vibrate. Their limited pressure tolerance means they can't be used in high-pressure systems, where blind flanges with bolted connections are more reliable. The ability to use exact torque values on blind flange bolting makes sure that the seal works the same way every time for the whole service life.

Blind Flange and Blind Spool, Plate Flange, and Flange Cover

Blind spools have flanges on both ends and a closed center section. This design makes them good for short-term pipeline sections but requires more material and is more expensive. Plate flanges can seal similarly, but they might not have the same strength that well-designed blind flanges do. Flange covers can be used to temporarily protect flanges, but they usually don't have the pressure ratings needed to be used in real operations.

The mechanical design of blind flanges spreads stress more evenly across the flange face, so there is less chance of bending under pressure. Their standard construction means that many different suppliers can get them, which gives you more freedom in how you buy them and lets you choose between a range of prices.

Trusted Chinese Blind Flange Exporters: What Sets Them Apart?

China is a top producer of industrial piping parts because it has put a lot of money into production technology, quality systems, and export infrastructure. These skills lead to dependable supply chains that help with difficult industrial projects around the world.

An Overview of China's Blind Flanges Manufacturing Strength

Chinese factories have built up a wide range of production skills, including everything from working with raw materials to testing the finished products. Flange blanks with consistent grain structure and mechanical properties are made by large-scale forging facilities. Advanced machining centers make sure that the dimensional tolerances and surface finishes are exact and meet global standards.

The focus of a lot of businesses on the same areas allows them to share resources and make their supply chains more efficient, which leads to lower prices. With this clustering effect, you can quickly increase the amount of production while keeping the quality up with known networks for quality control and testing facilities.

RAYOUNG: The Name You Can Trust for Quality Blind Flanges

RAYOUNG is a trustworthy maker of industrial pipe fittings. They make high-quality blind flanges that make sure pipeline connections are safe. Our wide range of products includes buttweld steel elbows, steel reducers, and flanges that work with a lot of different types of projects, from basic uses to complicated industrial systems.

The GOST-R and SGS certifications prove that our manufacturing capabilities meet the standards for quality and compliance with exports that are required around the world. The ISO 9001:2015 quality management system makes sure that all manufacturing operations have the same way of making things and that products always work well. This certification framework lays the groundwork for making blind flanges that can meet the tough standards of Armenia's industrial projects.

We are experienced manufacturers of pipes and fittings, so we know how important accurate engineering and strong materials are in industrial settings. Our blind flanges have the performance, safety, and long-lasting strength needed for everything from home plumbing to big industrial projects.

Practical Guide for Ordering Blind Flanges from China

Systematic methods that look at technical details, quality needs, and delivery times are needed for procurement to work well. Knowing how things are done helps people avoid mistakes and make sure their projects turn out well.

The procurement process in steps

The procurement process starts with technical specifications that include size, materials, pressure ratings, and relevant standards. During the quoting and production stages, make sure there is no confusion by giving full drawings or reference standards. In the first question, the amount needed, when it should be delivered, and the need for quality paperwork should be included.

Ask for detailed quotes that include information on material grades, testing requirements, packaging methods, and delivery terms. Look at several suppliers in terms of how technically skilled they are, how they get quality certifications, and how much experience they have working on projects. Negotiate payment terms that take both the need to manage risk and the needs of the supplier into account. Usually, this means paying in advance to get materials and paying the rest of the money when the shipping papers are received.

Approval of the sample sets standards for quality that must be met before production of the goods can start. Go over the surface finish quality, dimensional reports, and material certificates to make sure that they meet the requirements. Approve the samples in writing to set clear quality standards for the whole order.

Advice on How to Make Sure Quality and Reliability

Quality assurance starts when you choose a supplier and ends when you accept the delivery. Check the suppliers' credentials and ask for references from the same kind of projects to make sure they are skilled and trustworthy. Make clear the quality you expect, as well as how inspections and tests will be done and how records will be kept.

For important tasks or large amounts, you might want to use a third-party inspection service. Independent inspectors give unbiased proof of quality and in-depth reports that help people decide to accept the quality. Checking dimensions, testing materials, and looking over things based on certain standards are all parts of their service.

Conclusion

When you choose Chinese blind flange exporters for work in Armenia, you should look at their technical knowledge and quality certifications to make sure they are trustworthy. Industrial projects depend on parts that will meet high standards and keep working safely over time. Chinese manufacturers have shown they can make high-quality blind flanges that conform to global norms and meet the needs of specific projects. Procurement teams can build good partnerships that help get projects done and keep the business running by regularly rating their suppliers and making sure their technical needs are heard.

Frequently Asked Questions

1. What materials are best for blind flanges that will be under a lot of pressure?

Carbon steels like ASTM A105 or A350 LF2 work well under a lot of pressure because they are very strong. In difficult conditions, stainless steel 316 and 316L are less likely to rust. On the other hand, ASTM A182 F11 or F22 alloy steels do a good job in hot conditions. The material that is used will be affected by the temperature range, pressure class, and fluid compatibility needs.

2. How long is the normal lead time when buying from exporters in China?

Making and shipping standard blind flanges usually takes three to four weeks. It could take six to eight weeks if you use custom specifications. The delivery date depends on the number of materials available, the size and difficulty of the order, the number of items, and the requirements for quality testing. Rush orders might be filled if they don't take too long, and extra fees are paid.

3. Can you make custom blind flanges for piping systems that aren't like any others?

Yes, blind flanges can be made to fit any size, be made of any material, have any bolt pattern, and have any kind of surface finish. Some of the custom choices are special alloys, uncommon coatings, and making the parts bigger or smaller so they work with your system. Provide detailed drawings and specifications to ensure the fit and correct production is in place.

Connect with RAYOUNG for Premium Blind Flange Solutions

RAYOUNG makes all kinds of blind flanges, which help a wide range of industries in Armenia by providing dependable, certified goods that meet global standards. Our experienced team offers technical advice to make sure you choose the right product for your needs. We offer great prices on quality ASME flanges with reliable delivery schedules. We can also make custom flanges to meet your needs. Talk to our blind flange experts to go over your project needs and get a full quote. For expert help and dependable ways to get blind flanges, email us at info@hb-steel.com.

References

1. Smith, J.R. and Anderson, M.K. "Industrial Flange Applications in Pipeline Systems: A Comprehensive Guide to Selection and Installation." International Journal of Pipeline Engineering, Vol. 45, No. 3, 2023.

2. Chen, LL.W".Chinese Manufacturing Excellence in Pipeline Components: Quality Systems and Export Standards." Global Industrial Manufacturing Review, 2023.

3. Petroyan, A.S. ."Armenia's Industrial Infrastructure Development: Procurement Strategies for International Suppliers." Armenian Industrial Development Quarterly, Vol. 12, No. 4, 2023.

4. Williams, R.D ."Comparative Analysis of Flange Types in High-Pressure Applications: Performance and Cost Considerations." Pipeline Technology International, 2023.

5. Zhang, H.M ."Export Quality Management in Chinese Pipe Fitting Manufacturing: Case Studies and Best Practices." China Manufacturing Excellence Journal, 2023.

6. Thompson, K.A. and Miller, S.J ."International Procurement Guidelines for Industrial Piping Components: Risk Management and Supplier Evaluation." Industrial Procurement Management Review, 2023.