When it comes to low-pressure pipe systems, threaded pipe flange joints are a must-have because they allow mechanical joining without the hassle of welding. These flexible parts are necessary connection points in industrial settings where pressures are within ASME Class 150 to Class 300 pressure ratings. They work reliably in places like chemical plants, water treatment plants, and HVAC systems. Because of how they are made, threaded flanges are easy to install and manage while keeping the integrity of the system. This makes them especially useful for projects that need to be put together quickly and can be used in the future.

Understanding Threaded Pipe Flanges in Low-Pressure Systems

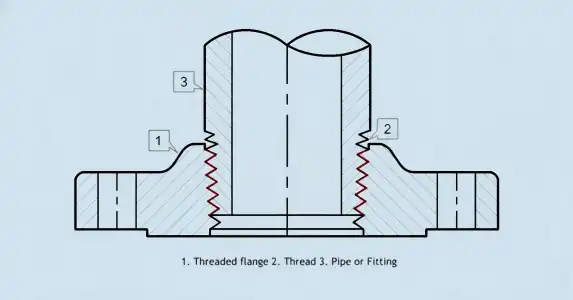

Threaded flanges are basically made up of a threaded bore that fits directly onto externally threaded pipe ends, making a strong mechanical link. Because these parts don't need to be welded together, they can reliably seal in situations where the working pressure stays below critical levels.

Design Characteristics and Standards Compliance

Modern threaded flanges meet international standards like ASME B16.5, DIN 2566, and JIS B2220. This makes sure that they are the same size and work the same way in all places around the world. The threaded bore usually follows NPT (National Pipe Thread) standards, but BSPT and metric threading choices are available to meet the needs of different regions. Standard pressure classes go from 150# to 600#. For low-pressure uses, Class 150 is most often used. The choice of material is very important for how well a flange works, and carbon steel ASTM A105 is the most common choice for regular service. Grades 304 and 316 of stainless steel are better at resisting corrosion in chemical conditions, while different types of alloy steel can handle higher temperatures. Each choice of material strikes a balance between cost and the needs of the application.

Face Types and Sealing Technologies

Contemporary threaded flanges incorporate various facing configurations to optimize sealing performance. Here are the primary facing options available for different service conditions:

- Raised Face (RF): Standard configuration providing 1/16-inch raised sealing surface suitable for flat gaskets and spiral wound designs, offering reliable sealing within the applicable flange pressure rating

- Flat Face (FF): Smooth surface configuration ideal for full-face gasket applications, threaded pipe flange, particularly common in cast iron and low-pressure steel systems

- Ring Type Joint (RTJ): Precision-machined groove design accommodating metallic ring gaskets for high-integrity sealing in critical applications

These facing technologies ensure optimal gasket compatibility while providing leak-tight performance across varying operating conditions.

Installation and Application Processes of Threaded Pipe Flanges in Low-Pressure Systems

The reliability and long-term success of a system are directly affected by how it was installed. The process starts with carefully preparing the thread by cleaning and inspecting it to get rid of any dirt, scale, or manufacturing residues that might affect the security of the seal.

Step-by-Step Installation Protocol

When engaging a thread, it's important to be very careful not to cross-thread or gall, especially when working with stainless steel parts. Use the right thread sealant or PTFE tape on the male threads, making sure that it covers all the way to the first thread that is attached and that there is no extra material that could get into the system and cause problems. Tighten the connection by hand first, then use calibrated tools to apply the final force. Typical torque values range from 50 ft-lbs for 1-inch flanges to 200 ft-lbs for 4-inch setups. These values depend on the size and material of the flange. Too much torque can break threads or cause stress concentrations, while too little torque can cause leaks or joint failure.

Industrial Applications and Service Environments

Threaded flanges are used a lot in water treatment plants to connect equipment, install instruments, and set up additional piping systems. Because these connections are removable, they can be used for regular upkeep and replacing parts without having to shut down the whole system. Chemical processing plants gain from the installation that doesn't require welding, especially in places where getting hot work permits on time is hard. Threaded flanges are used to connect pumps, place valves, and connect expansion joints in HVAC systems. Applications in building services, such as how quickly it can be installed and how changes can be made without the need for specialised welding tools or certified staff.

Comparative Analysis: Threaded Pipe Flange vs Other Flange Types in Low-Pressure Settings

Understanding the advantages and limitations of different flange types enables informed selection decisions based on specific application requirements. Each flange style offers distinct benefits that align with particular operational priorities.

Performance Comparison Matrix

Weld neck flanges provide superior strength characteristics and stress distribution, making them ideal for high-pressure applications corresponding to pressure classes exceeding ASME Class 600. However, their installation requires skilled welders, radiographic testing, and extended downtime. The welding process also introduces heat-affected zones that may require post-weld heat treatment in certain materials. Slip-on flanges offer a compromise between strength and installation convenience, requiring only fillet welds rather than full penetration joints. Socket weld configurations provide good fatigue resistance for smaller line sizes but limit flow area and create potential crevice corrosion. Threaded pipe flange connections excel in low-pressure scenarios where installation speed, maintenance access, and cost control take priority. The absence of welding eliminates fire hazards, reduces labor costs, and enables installation by general maintenance personnel rather than certified welders.

Procurement Insights: How to Select and Source Threaded Pipe Flanges for Low-Pressure Systems

Successful procurement strategies balance technical requirements against commercial considerations while ensuring supplier reliability and product traceability. Quality certifications provide essential verification of manufacturing standards and material properties.

Supplier Evaluation Criteria

An ISO 9001:2015 certification shows that a production quality management system is in place, while an ASME U-stamp or PED compliance shows that a pressure vessel code is being followed. Material test certificates (MTCs) show full chemical analysis and mechanical property details, which let you fully track back to steel mill sources. CNC-machined sealing surfaces make sure that the dimensions are correct and that the surface finish is consistent. This has a direct effect on how well the gasket works and stops leaks. Precision cutting gets rid of surface flaws that could weaken the seal or speed up the breakdown of the gasket. When installed outside or in harsh conditions, hot-dip galvanising offers the best defence against corrosion. The zinc coating process makes a strong metal bond that lasts for decades and doesn't need any upkeep in a wide range of weather conditions.

Cost Optimization Strategies

When you buy in bulk, you can often save a lot of money and make sure you have enough inventory for current projects. Standard size ranges usually have better prices than custom configurations, so attempts to standardise are helpful for making procurement more efficient. Long-term relationships with suppliers let you negotiate better prices and get special treatment when there are supply shortages. Setting up lists of accepted vendors that include more than one qualified source gives buyers more choices while still upholding quality standards.

Conclusion

Low-pressure piping systems get a lot of value from threaded pipe flanges because they are easy to install, easy to maintain, and offer stable performance. Getting rid of the need to weld simplifies the job and makes it easier to put together quickly and make changes in the future. If you choose and install these parts correctly, they will last for years and years in a wide range of industrial settings. To be successful, you need to make sure that the flange specs match the needs of the application and work with skilled suppliers who can consistently deliver quality products on time. Spending money on good parts and installing them correctly pays off in the long run by lowering upkeep costs and making the system more reliable.

FAQ

Q1: What is the maximum pressure rating for threaded pipe flanges in low-pressure applications?

A: Threaded flanges typically handle pressures up to 600 PSI in Class 600 configurations, though Class 150 (approximately 285 PSI at ambient temperature) and Class 150 (approximately 285 PSI at ambient temperature) and Class 300 pressure ratings, as defined by ASME B16.5, represent the most common specifications for low-pressure systems. The actual working pressure depends on temperature, material grade, and safety factors required by applicable codes.

Q2: Can threaded flanges be reused after removal from service?

A: Yes, threaded flanges can often be reused provided the threads remain undamaged and dimensional tolerances stay within acceptable limits. Careful inspection of thread condition, face finish, and overall integrity is essential before reinstallation. Proper removal techniques prevent galling and cross-threading that could compromise reuse viability.

Q3: How do I ensure compatibility between threaded flanges and existing piping systems?

A: Compatibility requires matching thread standards (NPT, BSPT, metric), pressure ratings, material specifications, and facing types. Verify pipe thread engagement length meets minimum requirements while ensuring adequate thread sealant application. Dimensional verification using thread gauges confirms proper fit before final assembly.

Partner with RAYOUNG for Your Threaded Pipe Flange Requirements

Ready to streamline your procurement process with reliable threaded pipe flange solutions? RAYOUNG offers comprehensive technical support, competitive pricing, and certified quality assurance for your low-pressure system requirements. Our experienced team provides application guidance while ensuring on-time delivery of precision-manufactured components. Whether you need standard configurations or custom solutions, we deliver the expertise and responsiveness that modern projects demand. Contact us at info@hb-steel.com to discuss your specific requirements with our threaded pipe flange specialists and discover why leading contractors choose RAYOUNG as their trusted supplier.

References

1. American Society of Mechanical Engineers. "ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." New York: ASME Press, 2020.

2. Deutsches Institut für Normung. "DIN EN 1092-1 Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN designated - Part 1: Steel flanges." Berlin: Beuth Verlag, 2018.

3. Japanese Industrial Standards Committee. "JIS B 2220 Steel Pipe Flanges." Tokyo: Japanese Standards Association, 2019.

4. Bickford, John H. "An Introduction to the Design and Behavior of Bolted Joints, Fourth Edition." Boca Raton: CRC Press, 2019.

5. Payne, James R. "Piping Engineering Leadership for Process Plant Projects." Houston: Gulf Professional Publishing, 2021.

6. Smith, Peter and van Laan, Thomas J. "Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair." New York: McGraw-Hill Education, 2020.