Steel Pipe Flange Dimensions & Ratings: How to Choose the Right Class

Choosing the right pipe flange dimensions and evaluations is significant for guaranteeing the security, efficiency, and life span of your channeling framework. Whether you're an EPC temporary worker, wholesaler, or mechanical end-user, understanding how to select the fitting rib lesson can minimize venture dangers, guarantee compliance, and optimize your in general system performance. This comprehensive direct will walk you through the fundamental components to consider when selecting steel pipe spines, counting measurements, weight evaluations, and industry standards. When it comes to selecting the right rib course, a few key variables come into play. The most basic contemplations are the greatest working weight and temperature of your framework, the spine fabric, and adherence to industry measures like ASME B16.5. The "course" of a rib is specified by a dimensionless number (such as Class 150, 300, or 600) that demonstrates its capacity to withstand weight at particular temperatures. By understanding these components and how they interrelate, you can make educated choices that guarantee the security and unwavering quality of your channeling systems.

How to measure a pipe flange?

Accurately measuring a pipe flange is the first step in selecting the right component for your system. Here's a step-by-step guide to help you measure a pipe flange correctly:

Determine the Flange Type

Before measuring, identify the type of flange you're dealing with (e.g., weld neck, slip-on, blind). This will affect which measurements are most relevant.

Measure the Nominal Pipe Size (NPS)

The NPS is the approximate inner diameter of the pipe. For most flanges, this corresponds to the inner diameter of the flange bore.

Measure the Outside Diameter (OD)

Use a caliper or tape measure to determine the outside diameter of the flange at its widest point.

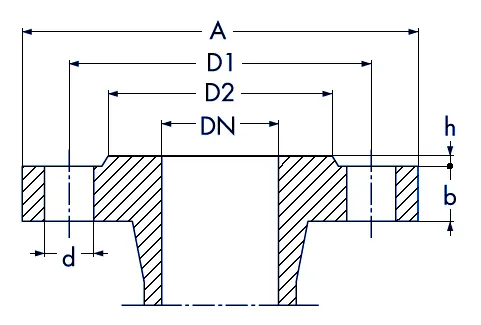

Measure the Bolt Circle Diameter (BCD)

The BCD is the diameter of the imaginary circle that passes through the center of all bolt holes. Measure from the center of one bolt hole to the center of the opposite hole, then divide by two.

Count and Measure Bolt Holes

Count the number of bolt holes and measure their diameter. Also, note the bolt hole pattern (e.g., equally spaced or special pattern).

Measure the Flange Thickness

Measure the thickness of the flange from the back face to the raised face or flat face.

Determine the Facing Type and Raised Face Height (if applicable)

Identify whether the flange has a raised face, flat face, or ring-type joint. For raised face flanges, measure the height of the raised portion.

By precisely measuring these measurements, you'll be way better prepared to select a spine that matches your framework necessities and guarantees a legitimate fit. Keep in mind, accuracy is key when it comes to pipe flange dimensions, as indeed little disparities can lead to spills or framework failures.

What are the standard pipe flange dimensions, and which codes govern them?

Understanding standard pipe flange dimensions and the codes that administer them is fundamental for guaranteeing compatibility and compliance in your channeling frameworks. Let's dive into the key benchmarks and measurements you require to know:

ASME B16.5: The Primary Standard

The American Society of Mechanical Engineers (ASME) B16.5 standard is the most widely recognized code governing pipe flange dimensions and ratings for sizes NPS 1/2" through NPS 24". This standard covers:

- Pressure-temperature ratings

- Materials

- Dimensions

- Tolerances

- Marking

- Testing

- Methods of designation

ASME B16.47: Large Diameter Flanges

For larger flanges (NPS 26" through NPS 60"), ASME B16.47 is the go-to standard. It's divided into two series:

- Series A (MSS SP-44): Covers dimensions for large diameter steel flanges

- Series B (API 605): Provides dimensions based on API standards

Key Dimensions Specified in Standards

The standards typically define the following dimensions:

- Outside Diameter (OD)

- Bore Diameter

- Bolt Circle Diameter (BCD)

- Number and Size of Bolt Holes

- Flange Thickness

- Raised Face Height (if applicable)

Other Relevant Standards

While ASME standards are predominant in North America, other regions may use different codes:

- EN 1092: European standard for spines and their joints

- ISO 7005: Universal standard for metallic flanges

- JIS B 2220: Japanese Mechanical Standard for steel pipe flanges

Understanding these benchmarks, including pipe flange dimensions, is significant for guaranteeing that your spines meet administrative necessities and are consistent with other components in your channeling framework. Continuously allude to the most recent form of the pertinent standard when indicating or selecting spines for your project.

Understanding Pressure Classes — Class 150 vs Class 300

When selecting spines based on pipe flange dimensions and appraisals, understanding weight classes is significant. Two commonly utilized classes are Lesson 150 and Class 300. Let's investigate their characteristics and applications:

Class 150 Flanges

Class 150 flanges are the most common and economical choice for many applications. Key points include:

- Suitable for weights up to 285 psi at surrounding temperature (carbon steel)

- Pressure rating diminishes as temperature increases

- Commonly utilized in medium to heavy-weight applications

- Lighter and less costly than higher-pressure classes

Class 300 Flanges

Class 300 flanges are designed for higher-pressure applications. Important characteristics include:

- Suitable for weights up to 740 psi at surrounding temperature (carbon steel)

- Higher weight evaluations over all temperatures compared to Class 150

- Used in medium to high-pressure systems

- Thicker and more vigorous than Class 150 flanges

Comparing Class 150 and Class 300

When choosing between Class 150 and Class 300 flanges, consider:

- Operating Weight: Course 300 can handle higher pressures altogether.

- Temperature Extend: Both classes see decreased weight evaluations at higher temperatures, but Class 300 maintains higher evaluations throughout.

- Cost: Lesson 300 ribs are, by and large, more costly due to expanded fabric and fabricating requirements.

- Weight: Lesson 300 ribs are heavier, which may affect establishment and bolster requirements.

- Bolt Measure and Number: Course 300 spines regularly have bigger and more varied jolts for expanded strength.

Selecting the suitable weight lesson is basic for guaranteeing framework security and life span. Continuously consult the significant pressure-temperature rating tables in the pertinent measures (e.g., ASME B16.5) to determine the correct weight appraisals for your particular fabric and working conditions.

Remember, whereas Class 150 and Class 300 are common choices, higher weight classes (e.g., Class 600, 900, 1500) and pipe flange dimensions are accessible for more demanding applications. Continuously prioritize security and compliance when selecting spines for your channeling system.

Conclusion

Selecting the right steel pipe flange dimensions and appraisals is a basic choice that impacts the security, efficiency, and life span of your channeling framework. By understanding how to degree ribs precisely, familiarizing yourself with pertinent guidelines, and getting a handle on the contrasts between weight classes, you can make educated choices that minimize dangers and guarantee ideal performance.

Remember to consider variables such as working weight, temperature, fabric compatibility, and industry benchmarks when selecting ribs. Whether you're managing with low-pressure frameworks that can utilize Class 150 spines or high-pressure applications requiring Class 300 or over, careful thought of all variables is essential.

For EPC temporary workers, merchants, and mechanical end-users looking for high-quality steel pipe ribs and fittings, HEBEI RAYOUNG PIPELINE Technology CO., LTD offers a comprehensive range of arrangements. Our items are designed to meet different needs, from clear establishments to complex mechanical applications.

With our commitment to quality, security, and development, RAYOUNG stands as a trusted accomplice in the channeling industry. Our products are supported by GOST-R and SGS certifications, guaranteeing compliance with universal measures and send out controls. Whether you're working on water frameworks, gas lines, or mechanical plants, our skill in pipe fittings can offer assistance you accomplish solid, long-lasting installations.

Don't compromise on quality when it comes to your channeling systems. Contact RAYOUNG nowadays to examine your particular needs and find how our run of steel pipe spines and fittings can contribute to the success of your ventures.

FAQ

Q1: What factors should I consider when selecting a flange class for my piping system?

A: When selecting a rib lesson, consider the following key components: most extreme working weight and temperature, spine fabric compatibility with the liquid being transported, pipe size and divider thickness, compliance with industry guidelines, rib sort and confronting, and gasket compatibility. These components collectively decide the fitting lesson that will guarantee the security, execution, and lifespan of your channeling system.

Q2: How do I determine the pressure rating of a specific flange class at different temperatures?

A: To decide the weight rating of a spine course at distinctive temperatures, consult the pressure-temperature rating tables given in the significant industry standard, such as ASME B16.5. These tables show how the most extreme admissible working weight changes with temperature for diverse materials and rib classes. Continuously utilize the most current adaptation of the standard to guarantee accuracy.

Q3: Can I use a higher-class flange in a lower-pressure system?

A: Yes, you can utilize a higher-class spine in a lower-pressure framework. For example, a Class 300 rib can be utilized in a system planned for Class 150 weight evaluations. Be that as it may, this may not be cost-effective as higher-class ribs are regularly more costly. It's imperative to adjust security requirements with financial considerations when making such decisions.

Expert Flange Selection Guide for Your Piping Projects | RAYOUNG

Ready to ensure the safety and efficiency of your piping system with the right pipe flange dimensions and flange selection? RAYOUNG is here to help. Our team of experts can guide you through the process of choosing the perfect flanges for your specific application, whether you're working on a small-scale project or a large industrial installation.

Don't leave your flange selection to chance. Contact us today at info@hb-steel.com for personalized assistance and access to our wide range of high-quality steel pipe flanges and fittings. Let RAYOUNG be your trusted partner in building reliable, long-lasting piping systems that meet and exceed industry standards.

References

1. American Society of Mechanical Engineers. (2017). ASME B16.5-2017 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard.

2. Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill Education.

3. American Petroleum Institute. (2018). API Specification 6A - Specification for Wellhead and Christmas Tree Equipment.

4. International Organization for Standardization. (2011). ISO 7005-1:2011 Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems.

5. Mohinder L. Nayyar, P.E. (2017). Piping Databook (2nd ed.). McGraw-Hill Education.

6. Smith, P., & Van Laan, R. (2018). Piping and Pipe Support Systems: Design and Engineering. CRC Press.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise