Everyone who works with pipes needs to know how to put slip-on flanges so that pipe connections stay stable. You can connect these components to pipes by sliding them over the pipe end and securing them through welding, without complex machining operations. Because of this, they are very useful in many business settings. Slip-on flanges are designed to firmly connect pipes directly. When properly designed, welded, and installed, they are capable of withstanding elevated temperatures and pressures without compromising joint integrity. This full guide teaches beginners how to install things, fix problems, and choose the right things so they can get professional-level results while keeping costs and risks as low as possible.

Understanding Slip-On Flanges: Design and Features

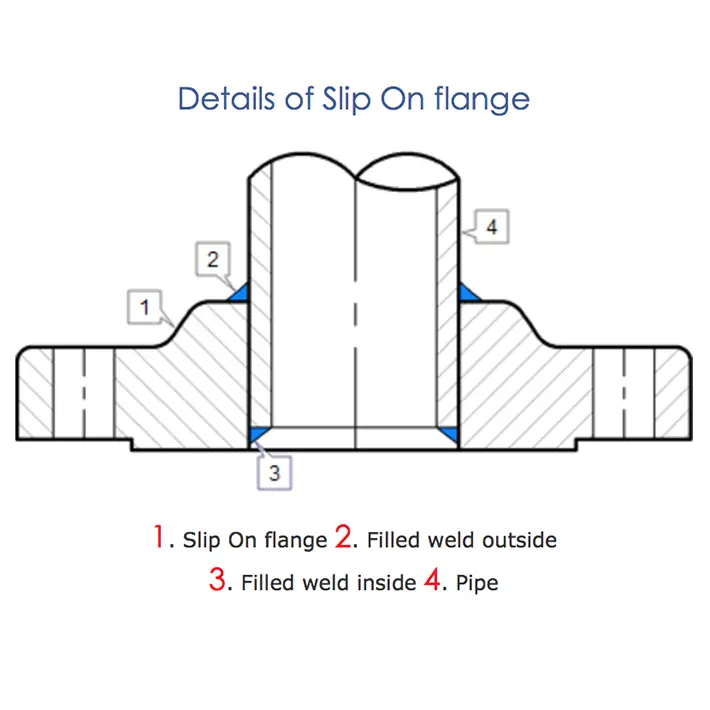

Slip-on flanges are very useful in current pipe systems because they are easy to install and have a simple shape. It is a little bigger on the inside of these round, flat parts than it is on the outside of the pipe. They can easily slide over the pipe end because of this. With the hub part, there is more metal to weld, and the mechanical bond between the flange and pipe is strong.

Material Composition and Standards

Slip-on flanges can be made from many different materials these days, so they can be used in many tasks. Carbon steel options are strong and cheap enough for general industrial use, while stainless steel options are better at preventing corrosion in harsh conditions. When used in places with high temperatures, alloy steel flanges do a better job. All high-quality flanges are made to meet standards for dimensions like ASME B16.5 and DIN standards. There are different types of flanges, but they all work together and do the same job.

Pressure and Temperature Ratings

To choose the right flange, you need to know about the pressure class rates. Slip-on flanges are typically manufactured in ASME pressure classes ranging from Class 150 to Class 2500, depending on material grade and design requirements. Temperature rates depend a lot on the material used. For example, carbon steel flanges can operate at temperatures well above 400°F, depending on pressure class and material grade, while stainless steel versions can handle temperatures over 800°F in many situations.

Step-by-Step Slip-On Flange Installation Guide for Beginners

The long-term dependability and safety of flange joints depend on how they were installed. To get the best results, you need to pay close attention to every detail and follow the best methods in your field at every step.

Preparation and Initial Setup

Before you start installing, make sure that the pipe end and flange areas are clean. This will get rid of any dirt, oil, or oxidation that might affect the quality of the weld. Check the pipe's dimensions to make sure they are correct. Make sure the outside diameter fits the flange's internal bore specifications. Make sure the pipe end is cut square and smooth so there are no alignment issues during fitting. Compare the flange's measurements to the project's requirements and make sure that the material's certifications match the design needs.

Positioning and Alignment

Carefully slide the flange over the end of the pipe until it is the right distance away from the end of the pipe. The pipe should go through the hub of the flange about 1/8 inch to 1/4 inch, based on the thickness of the wall and the welding requirements. To keep things concentrically aligned and avoid angular misalignment that could cause stress clusters in the finished joint, use alignment tools or fixtures.

Welding Procedures

Welding Steps: Tack-weld around the edge of the ring to make sure it's in place before finishing the welding. At 90-degree intervals, use small tack welds and check the line after each one. Finish the fillet weld on the inside by using the right welding methods for the base materials. Then do the outer fillet weld, Slip-on flanges, making sure to keep the heat input and travel speed the same to make sure the weld goes through evenly and with minimal distortion.

Post-Installation Inspection

Check the finished welds carefully with a torch to make sure they have the right shape, enough penetration, and no flaws like cracks, holes, or missing fusion. Do the non-destructive testing that was asked for, such as dye penetrant testing or magnetic particle screening for important tasks. Check the dimensions to make sure the flange face stays straight and parallel to the pipe centerline. It must also meet the standards for flatness.

Common Challenges and How to Avoid Installation Mistakes

Understanding potential pitfalls helps prevent costly rework and ensures installation success. Many common issues stem from inadequate preparation or rushing through critical steps in the installation process.

Alignment and Fit Problems

Misalignment represents the most frequent installation challenge, often resulting from improper pipe preparation or inadequate fixturing during welding. Pipe ends must be cut square within specified tolerances to prevent angular misalignment. Use proper alignment tools and check concentricity throughout the welding process to maintain dimensional accuracy. Address any misalignment immediately through realignment or rework procedures rather than attempting to compensate through gasket compression.

Welding Defects and Quality Issues

Welding defects compromise joint integrity and system safety. Poor surface preparation leads to contamination and incomplete fusion, while excessive heat input causes distortion and metallurgical problems. Maintain consistent welding parameters and use qualified welding procedures for the specific material combination. Control interpass temperatures and implement proper cooling practices to minimize thermal stress and distortion.

Dimensional Inaccuracies

Dimensional problems often happen because of bad measurements or a misreading of the specifications. Before starting the job, make sure that all the measurements match up with the current plans and specs. In high-temperature situations, you should think about how thermal expansion might affect things and make sure there is enough space for thermal growth. For quality control reasons, Slip-on flanges write down all measurements and keep dimensional records.

Slip-On Flange vs Other Flange Types: Installation and Usage Comparison

By comparing the different types of flanges, you can find the best one for your needs and the limitations of your installation. Each type of flange has its own benefits that depend on the pressure needs, the difficulty of fitting, and the cost.

Installation Complexity Analysis

Slip-on flanges are much easier to install than weld neck flanges because the pipe doesn't need to be prepared as precisely, and the welding process is simpler. Slip-on designs, unlike socket weld flanges, don't have to worry about crevice corrosion, making it easy to check the welded joint. Slip-on flanges are better suited for permanent installations because they are easier to position and provide welded joints, unlike threaded flanges which rely on mechanical threads.

Performance and Cost Considerations

Cost analysis reveals slip-on flanges typically require 30-40% less installation time compared to weld neck alternatives, translating to significant labor cost savings on large projects. Material costs remain comparable across flange types of similar specifications, making installation efficiency the primary economic differentiator. Performance characteristics vary based on application requirements, with slip-on flanges excelling in low to medium pressure applications while weld neck flanges handle higher pressures more effectively.

Procurement and Supply Considerations for Slip-On Flanges

Strategic procurement decisions impact project timelines, costs, and overall system reliability. Understanding market dynamics and supplier capabilities enables better sourcing decisions and risk management.

Supplier Selection Criteria

Evaluate potential suppliers based on quality certifications, manufacturing capabilities, and delivery performance. ISO 9001:2015 certification demonstrates commitment to quality management, while industry-specific certifications like API or ASME indicate specialized expertise. Review supplier quality control procedures, testing capabilities, and traceability systems to ensure consistent product quality. RAYOUNG maintains comprehensive certifications, including GOST-R and SGS validation, ensuring export compliance and quality assurance for global markets.

Specification and Ordering Considerations

Clear sharing of specifications avoids delays and makes sure the right materials are chosen. Give full details about the size needs, types of materials, pressure values, and any other features you want, like the type of facing or protective coatings you want. You might want to standardise the flange specifications across all jobs to get volume discounts and make your inventory easier to manage. When making plans for purchases, remember to include wait times for manufacturing, especially for sizes or materials that aren't standard.

Conclusion

To install a slip-on flange correctly, you need to understand basic concepts, follow organised steps, and stay away from common mistakes that damage the system. These parts are easy for new pipe workers to use because they are simple, but they still need careful attention to detail and the right way to do things. Mastering installation methods, knowing what quality standards are, and knowing what to think about when buying things gives you the confidence to carry out projects and depend on systems to work as they should. Installations that are safe, effective, and meet project goals while minimising risks and costs are made possible by ongoing learning and following industry standards.

FAQ

Q1: What are the primary advantages of using slip-on flanges over other flange types?

A: Slip-on flanges offer simpler installation procedures, reduced labor costs, and effective sealing capabilities for low to medium-pressure applications. Their design allows for easier alignment and welding compared to weld neck flanges, while providing superior strength compared to threaded connections. The versatility and cost efficiency make them particularly valuable for water treatment, chemical processing, and general industrial piping systems.

Q2: What are the key steps to ensure proper slip-on flange welding and avoid defects?

A: Critical steps include thorough surface preparation, proper pipe end preparation, accurate positioning and alignment, systematic tack welding, complete interior and exterior fillet welding, and comprehensive post-weld inspection. Maintaining consistent welding parameters, controlling heat input, and using qualified welding procedures for specific material combinations prevent common defects such as porosity, incomplete fusion, and cracking.

Q3: Which materials are most suitable for slip-on flanges in corrosive or high-temperature environments?

A: Stainless steel grades like 316L provide excellent corrosion resistance for chemical environments, while duplex stainless steels offer enhanced strength and corrosion resistance. For high-temperature applications, alloy steels such as P11 or P22 deliver superior performance. Material selection depends on specific service conditions, including temperature, pressure, and chemical compatibility requirements.

Partner with RAYOUNG for Premium Slip-On Flange Solutions

RAYOUNG stands as your trusted slip-on flange supplier, delivering precision-engineered components that meet the highest industry standards. Our comprehensive product range includes carbon steel, stainless steel, and alloy flanges conforming to ASME, ANSI, and DIN specifications. With ISO 9001:2015 certification and extensive quality control systems, we ensure consistent performance and reliability for your critical piping applications. Whether you need standard configurations or custom solutions for complex projects, our technical expertise and manufacturing capabilities support your success. Contact us at info@hb-steel.com to discuss your requirements and discover why leading contractors choose RAYOUNG for their flange procurement needs.

References

1. American Society of Mechanical Engineers. "ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard." 2020 Edition.

2. Mohitpour, M., Golshan, H., and Murray, A. "Pipeline Design & Construction: A Practical Approach, Third Edition." ASME Press, 2007.

3. Nayyar, M.L. "Piping Handbook, Seventh Edition." McGraw-Hill Professional, 2000.

4. American Welding Society. "Structural Welding Code - Steel, AWS D1.1/D1.1M:2020." American Welding Society, 2020.

5. Barletta, N. "Piping Materials Guide." Gulf Professional Publishing, 1999.

6. Escoe, A.K. "Piping and Pipeline Assessment Guide." Gulf Professional Publishing, 2006.