Are seamless pipes always better than welded pipes for high-pressure service?

It's not always better to have pipes that aren't joined together than pipes that are. When used with high pressure, seamless lines are often better. The answer is based on several things:

Pressure Ratings

Seamless pipes can take more pressure because their structure is more even. But as welding technology has gotten better, smooth lines have become much better at withstanding pressure. This has often closed the gap.

Cost Considerations

Most of the time, it's cheaper to buy longer lines that have been joined together. Don't need to rush or have a lot of money? This could be very helpful for projects like those.

Availability

Most of the time, welded pipes are easy to find, come in more forms, and can be made more quickly. This can help with quick or small jobs.

Specific Application Requirements

For instance, some users may need to use smooth lines because of the rules of the code or because they have to work in tough circumstances. But sometimes, connected lines may work better and cost less.

Once you've made your choice, give it a lot of thought to see how it will fit with your idea. You should think about the power you need, how safe it is, how much it will cost, and business standards.

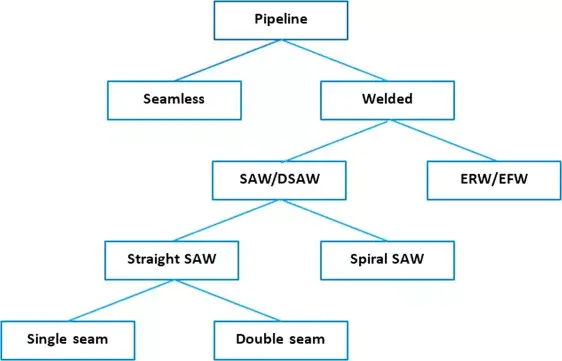

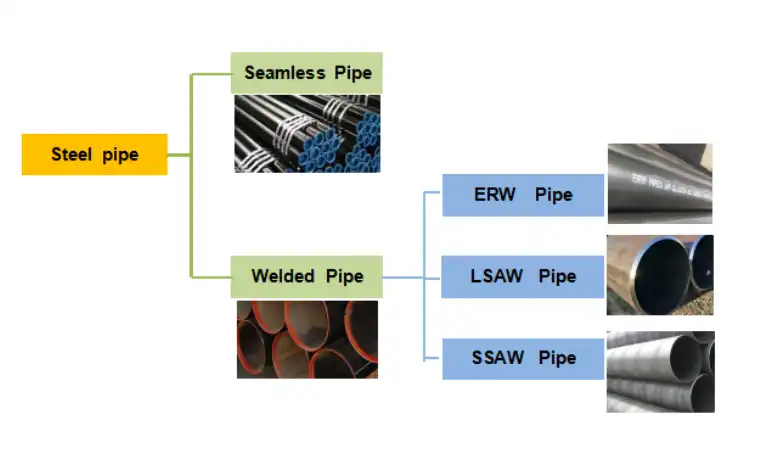

Structural differences: absence of seam in seamless pipes vs. welded seam implications

The way smooth pipes are made and the materials they are made of are different from linked pipes. This difference tells you a lot about how well they work and meet your goals.

Seamless Pipe Structure

You get an empty tube when you heat solid cylinder billets and then push or pull them over a mandrel. This is how you make lines that don't meet. With this method, a pipe is made that has a straight structure all the way through and no breaks along its length.

Advantages:

- Higher pressure resistance due to uniform wall thickness

- Better fatigue resistance

- Reduced risk of failure along seam lines

Limitations:

- Higher manufacturing costs

- Limited availability in very large diameters

Welded Pipe Structure

To make a welded pipe, you roll metal sheets or plates into a cylinder shape and then join the gap. The joint can go along the length of the pipe or around it in a circle.

Advantages:

- More cost-effective production, especially in larger sizes

- Greater flexibility in diameter and wall thickness options

- Faster production times

Limitations:

- Potential for weld defects if not properly manufactured

- May have lower pressure ratings compared to seamless pipes of the same material and dimensions

Implications for High-Pressure Applications

Smooth pipes are strong all the way through because they don't have any holes in them. When there is a lot of stress on them, this helps them work better. However, welded pipes are now much safer because of better welding methods and strict quality control checks. They can also be used in many high-pressure conditions.

Most of the time, seamless pipes are the best choice when safety and stability are very important, like in nuclear power plants or the oil and gas business. When the needed pressure is within the range of welded pipes, they can be a cost-effective choice that doesn't sacrifice performance.

Performance trade-offs: pressure capability, testing requirements, and certification

You should think about the changes in performance between seamless and welded pipes for high-pressure uses. These include how much pressure they can handle, how they need to be checked, and how they get approved.

Pressure Capability

Because they are all the same, seamless pipes can usually handle higher pressures. But the real pressure number is based on things like

- Material properties

- Wall thickness

- Pipe diameter

- Operating temperature

Welded lines used to be thought to be less able to handle high pressures, but they have come a long way since then. In many situations, high-frequency welded (HFW) and submerged arc welded (SAW) pipes can now handle the same amount of pressure as seamless pipes.

Testing Requirements

Both seamless and soldered pipes are put through a lot of tests to make sure they work well and aren't damaged. But pipes that have been joined often need extra tests that focus on the weld seam:

Seamless Pipes:

- Hydrostatic testing

- Non-destructive testing (NDT) such as ultrasonic testing

- Material composition analysis

Welded Pipes:

- All tests applied to seamless pipes

- Additional weld seam inspections (e.g., radiographic testing)

- Bend tests to evaluate weld ductility

Certification Processes

High-pressure pipes have strict certification needs that can change based on the business and the purpose. Important parts are:

- Material certifications, such as those based on ASTM or API standards

- Certifications for the process of making it

- Certifications for methods that keep an eye on quality, such as ISO 9001

- Third-party checks and inspections

This set of approval standards can be met by pipes that are either smooth or bonded. But because of how they are made, smooth pipes may work better in some high-pressure situations. But pipes that are protected and have the right licenses can also work in many high-pressure situations.

Making the Right Choice

When selecting between seamless and welded pipes for high-pressure lines, consider:

- Specific pressure requirements of your application

- Applicable industry standards and codes

- Cost-effectiveness over the project lifecycle

- Availability and lead times

- Some ideas for long-term maintenance

If you pay close attention to these things, you can choose a high-pressure pipe system that works well, is safe, and doesn't cost too much.

Conclusion

There is no one right answer when it comes to the question of whether high-pressure lines should be made of smooth or soldered pipes. Seamless pipes are better at withstanding pressure and being regular, but welded pipes have come a long way and can be used for many high-pressure tasks. The choice you make will rely on the needs of your job, your income, and your long-term operating needs.

When industrial end-users, EPC workers, and project managers need reliable, high-quality pipe solutions, they need to work with a reputable source that can offer a lot of choices and expert advice. HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD has a huge selection of seamless and welded pipes, valves, and other project-specific items.

It might be hard to pick the right lines for your wants. The skilled people on our team can guide you through the process and help you make the best choice. The goods we sell are strong and work well because they have been passed by ISO 9001:2015 and are very carefully checked for quality.

Don't let not knowing which pipes to use hurt the success of your project. Get in touch with RAYOUNG right away to talk about your high-pressure pipe needs and find out how our knowledge can help make your industrial systems safer, more efficient, and longer lasting.

FAQ

1. How do I determine if I need seamless or welded pipes for my high-pressure application?

The price you want to spend, the pressure you need, and the temperature where the lines will be used will all affect your choice. When there is a lot of pressure or the use is important, smooth pipes are often the best choice. On the other hand, modern lines that are joined together can handle a lot of high pressure well. It can help you make the right choice if you talk to someone you can trust, like RAYOUNG.

2. Are welded pipes always less expensive than seamless pipes?

Most of the time, bigger widths mean that welded pipes cost less than smooth pipes. Price gaps can change, though, depending on the market, the size, and the type of material used. Smooth pipes may be better in the long run than welded pipes sometimes, even if welded pipes cost less in the short term. Before you make a choice, you should think about the pros and cons in both the short and long run.

3. Can welded pipes be used in high-pressure oil and gas applications?

Welded pipes can be used in many high-pressure oil and gas uses as long as they meet the standards and requirements. The reliability of soldered pipes has greatly increased thanks to modern welding methods and strict quality control measures. However, smooth pipes may be required for uses with very high pressure or where industry standards say so. When choosing lines for oil and gas projects, you should always look at the appropriate industry norms and talk to professionals.

Expert Pipe Solutions for High-Pressure Applications | RAYOUNG

Are you ready to make sure you have a safe and well-working high-pressure pipe system? Ra Young has a lot of seamless and soldered pipes for you to choose from, and they can also help you figure out which one is best for your needs. We have strict quality control measures in place to make sure that our goods work well in any business setting. ISO 9001:2015 says that our goods are good.

If you want good high-pressure lines, don't skimp on them. Contact RAYOUNG today at info@hb-steel.com to discuss your project requirements and discover how our expertise can contribute to your success. Let us help you build a safer, more efficient, and cost-effective piping system that stands the test of time.

References

1. American Petroleum Institute. (2018). API Specification 5L: Specification for Line Pipe. Washington, D.C.: API Publishing Services.

2. American Society of Mechanical Engineers. (2019). ASME B31.3: Process Piping. New York: ASME.

3. Nayyar, M. L. (2000). Piping Handbook (7th ed.). New York: McGraw-Hill Education.

4. Singh, R. (2017). Applied Welding Engineering: Processes, Codes, and Standards (2nd ed.). Butterworth-Heinemann.

5. Antaki, G. A. (2003). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. CRC Press.

6. International Organization for Standardization. (2018). ISO 3183:2019 Petroleum and natural gas industries — Steel pipe for pipeline transportation systems. Geneva: ISO.