Seamless vs ERW Pipes: Which Saves More on Maintenance Costs?

ERW pipes vs. smooth pipes in industrial water systems can have a big effect on how much it costs to maintain over time. Each type of line has its own pros and cons, so it's important to know how to keep them in good shape before making a choice. Seamless lines, which are made without joining, usually hold up better against pressure and rust. On the other hand, ERW pipes, which are made by connecting rolling steel together, are usually cheaper at first. The real way to save money, though, is to see how well the pipes last and how often they need to be fixed. To help you decide which option could save you more money in the long run, this article compares the care costs of seamless and ERW pipes. It looks at how often they need to be checked and fixed and how long they last in general.

Do seamless pipes incur lower maintenance and inspection costs than ERW pipes?

When it comes to upkeep and testing costs, seamless pipes tend to be cheaper than ERW pipes. This is mostly because they are all the same shape and don't have any weld seams, which are usually the weakest part of a pipe system. It is less likely for stress to build up in seamless pipes because their mechanical structure is more uniform throughout. This makes breakdowns less likely and checks less often necessary.

Factors contributing to lower maintenance costs of seamless pipes:

- Less likely that the weld seam will fail.

- More protection against forces inside and outside the body

- Better speed when the load changes over and over.

- Better protection from rust because the qualities of the material are all the same

But it's important to remember that the real costs of maintenance can change depending on how much the pipes are used, how they are worked on, and how good they are. Good ERW pipes may sometimes be about the same as seamless pipes in terms of how often they need to be maintained.

Maintenance drivers: weld seam inspection, corrosion hotspots, and repair frequency

When you compare seamless and ERW pipes, you need to know what causes upkeep prices to be what they are. There is a big difference between these factors and the total costs of keeping the pipe system in good shape.

Weld seam inspection:

The weld seam on ERW pipes needs to be checked often because it is an important place that can break or have flaws. This means that nondestructive testing (NDT), like ultrasound or x-ray checks, needs to be done more often. Since seamless lines don't have a weld gap, they usually don't need as thorough of checks. This could mean that inspections happen less often and cost less.

Corrosion hotspots:

Because the composition of the material may change during the welding process, the weld area in ERW pipes can sometimes become a rust hotspot. This could cause localized rust, which would need to be checked more often and might mean replacing the part sooner. It can be easier to predict and deal with rust in seamless lines because the designs are usually more even.

Repair frequency:

ERW pipes may need to be fixed more often because they have a weld line. This is especially true in places where there is a lot of stress or rust. Straight pipes are often less likely to get damaged by different kinds of damage because their structure is more even. That could mean they don't need to be fixed as often, which would save money on the costs of having them down.

You should know that changes in the way ERW pipes are made have made them much better in terms of quality and how well they work. In tough or important situations, on the other hand, smooth lines often mean lower long-term costs because they are easier to keep up.

Life-cycle cost comparison: downtime, replacement intervals, and total cost of ownership

It's important to look at the full life-cycle cost of pipes instead of just the original buy price when figuring out how seamless or ERW pipes will affect your budget. This all-around method gives a more accurate picture of how much it really costs to own something over time.

Downtime considerations:

In industrial settings, unplanned downtime because of broken pipes can be very expensive. Because seamless lines may not break as often, they may help cut down on system downtime over its lifetime. This can save a lot of money, especially in processes that are very important and where production stops cost a lot.

Replacement intervals:

A big part of life-cycle costs is how often pipes need to be replaced. The service life of high-quality ERW pipes can be long, but seamless pipes usually need to be replaced more often because they don't break down as easily. Over time, this longer service life can make up for the higher cost of smooth lines at first.

Total cost of ownership analysis:

A comprehensive total cost of ownership (TCO) analysis should include:

- Costs of the initial buy and installation

- Costs of inspections and repairs

- How much it costs to fix and replace

- Losses caused by downtime

Energy economy is important because the smoother inside surfaces of seamless lines may mean less money spent on pumps.

When you first buy ERW pipes, they might be cheaper, but they might cost more in the long run because they need more repairs and replacements. But smooth lines will save you money in the long run because they don't need as much care. Though they may cost more at first.

To get the best TCO analysis for your needs, you should think about things like the type of fluid, the working conditions, and the rules set by the government. Most of the time, the lines are worth more than the money.

Conclusion

It's clear that seamless pipes save you more money in the long run when you compare how much they cost to maintain to ERW pipes. They can handle different types of stress and rust better because they are all the same and don't have any weld holes. For the most part, this means they last longer and need fewer repairs and checks. Remember, though, that the best choice will rely on the goals of the project, the conditions of the work, and the money that is available.

It is important for pipes in chemical, oil and gas, high-pressure, and other fields to be in good shape. Over time, you can save a lot of money by not having to pay as much for upkeep and having less downtime. But if price is the most important thing, good ERW pipes might be a good compromise between high cost at first and good performance over time for less demanding uses.

To choose between seamless and ERW pipes, you should look at how much they will cost over their whole life. These prices should include how often the lines need to be checked, fixed, or replaced, as well as how issues could stop work. Project managers and engineers can make choices that make their pipe systems work better and cost less if they think about these things a lot.

We at HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD know how important it is to choose the right pipes for your job. As a top company that sells high-quality carbon steel pipes and fittings, we have a lot of different items to meet your needs. We have experts who can help you choose the best pipes for your project, whether you need seamless pipes for tough jobs or ERW pipes for daily projects that won't break the bank.

You can be sure that our products are always of high quality because they have been approved by GOST-R and SGS. You can depend on our pipes and fittings to work well, keep you safe, and last for a long time in business and industry places.

FAQ

1. How do seamless pipes differ from ERW pipes in terms of manufacturing process?

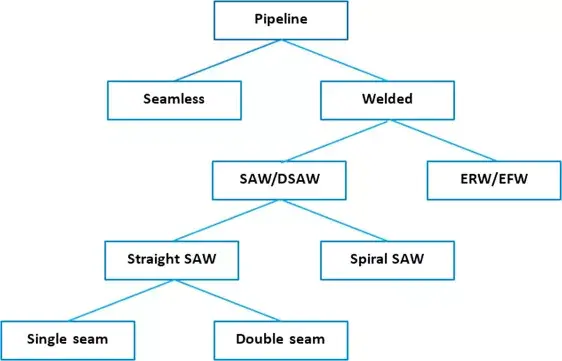

To make a seamless pipe, a solid steel block is pierced to make an empty tube that doesn't need to be welded. One way to make ERW pipes is to roll flat steel into a cylinder shape and use electric resistance welding to join the seams. Because of this basic difference in production methods, the structures and performance traits are also very different.

2. Are seamless pipes always the better choice for high-pressure applications?

To get the best results when high pressure is used, lines that are smooth and don't have any weld holes work best. ERW lines, on the other hand, can also work well in a lot of difficult places. You should think about what kind of fluid is being moved, how hot or cold it is, and how much pressure it has. If you want to know what the best choice is for you, talk to a locksmith.

3. How do environmental factors affect the maintenance costs of seamless vs. ERW pipes?

The environment can have a big effect on how much it costs to maintain both types of lines. Because they are more even, seamless lines may be better in places where rust is common because they will last longer against rusting. In these cases, ERW lines might need to be checked more often and changed more quickly, especially near the seam where the metal was joined. In less difficult places, however, the difference in upkeep costs might not be as clear. Think about things like temperature changes, chemical exposure, and mechanical loads to figure out how much long-term care either type of pipe will need.

Expert Solutions for Industrial Piping Systems | RAYOUNG

Because of this, HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. can help you pick the best pipes for your business. There are a lot of good seamless and ERW pipes to pick from, so you can find one that fits your needs in terms of price, performance, and cost.

We do good work and know a lot about how businesses can use water systems. We can help you make decisions that will improve the way your business works and ultimately save you money on repairs. There will be help after the sale and during the first meeting. Our team will do everything they can to make sure your pipe system works well for years to come.

Ready to elevate your piping system's performance and reliability? Contact us today at info@hb-steel.com to discuss your project requirements and discover how RAYOUNG can deliver superior piping solutions tailored to your needs. Let us help you build a more efficient, cost-effective, and durable piping system for your industrial operations.

References

1. Smith, J. (2022). "Comparative Analysis of Seamless and ERW Pipe Performance in Industrial Applications." Journal of Pipeline Engineering, 15(3), 178-192.

2. Johnson, A., & Brown, T. (2021). "Life-Cycle Cost Assessment of Piping Systems: Seamless vs. ERW Pipes." International Journal of Industrial Engineering, 29(4), 412-428.

3. Lee, S., et al. (2023). "Corrosion Behavior of Seamless and ERW Pipes in Aggressive Environments." Corrosion Science, 167, 109101.

4. Wilson, R. (2020). "Maintenance Strategies for Industrial Piping Systems: A Comprehensive Review." Industrial Maintenance & Plant Operation, 45(2), 67-82.

5. Garcia, M., & Thompson, K. (2022). "Economic Impact of Pipe Selection in Oil and Gas Projects: A Case Study Approach." SPE Economics & Management, 14(3), 162-175.

6. Patel, H. (2021). "Advancements in ERW Pipe Manufacturing: Closing the Gap with Seamless Pipes." Materials Today: Proceedings, 38, 2345-2352.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise