Seamless Pipes, Butt Weld Fittings, and Flanges: A Complete System Guide

Advanced mechanical foundation depends on the consistent integration of different pipe components to make dependable, effective channeling frameworks. Understanding how consistent channels, butt weld fittings, and spines work together shapes the establishment of fruitful mechanical ventures over different divisions. These fundamental pipe components must be carefully chosen and appropriately coordinates to guarantee ideal execution, security, and life span in requesting applications. This comprehensive direct investigates the basic viewpoints of each component sort, their interconnected connections, and best hones for making total channeling frameworks that provide extraordinary comes about over differing mechanical environments.

Understanding Seamless Pipe Systems and Their Applications

Manufacturing Processes and Quality Standards

Seamless channels speak to one of the most basic pipe components in advanced mechanical applications, made through advanced forms that kill longitudinal creases and potential powerless focuses. The hot rolling and cold drawing forms utilized to make consistent channels result in uniform divider thickness and predominant mechanical properties compared to welded options. These fabricating strategies guarantee that pipe components keep up steady dimensional precision and fabric properties all through their whole length, making them perfect for high-pressure and high-temperature applications. The nonappearance of weld creases in these pipe components kills push concentration focuses that might lead to untimely disappointment beneath requesting working conditions. Quality control measures all through the fabricating prepare incorporate ultrasonic testing, hydrostatic weight testing, and dimensional assessment to confirm that each consistent pipe meets exacting industry measures. The coming about pipe components show uncommon unwavering quality and execution characteristics that make them the favored choice for basic applications where disappointment is not an option.

Pressure Rating and Temperature Capabilities

The pressure and temperature capabilities of seamless pipe components significantly exceed those of welded alternatives due to their homogeneous material structure and absence of heat-affected zones. These pipe components can safely operate at pressures ranging from standard industrial levels to ultra-high pressures exceeding 1000 bar, depending on wall thickness and material grade. Temperature resistance varies with material selection, with carbon steel seamless pipes typically handling temperatures from -40°C to 400°C while maintaining their structural integrity. The uniform grain structure achieved during seamless pipe manufacturing ensures consistent thermal expansion characteristics across the entire component, preventing stress concentrations that could compromise system integrity. Advanced metallurgical processes used in producing these pipe components create fine-grained microstructures that enhance both strength and ductility under extreme conditions. The combination of superior pressure ratings and temperature capabilities makes seamless pipes the ideal choice for demanding applications in petrochemical, power generation, and high-pressure industrial processes.

Installation Considerations and System Integration

Proper establishment of consistent pipe components requires cautious consideration to taking care of, capacity, and joining procedures to keep up the judgment points of interest these items offer. The prevalent surface wrap up and dimensional precision of consistent channels encourage simpler establishment and decrease the require for broad field alterations amid framework get together. These pipe components ordinarily require specialized dealing with hardware due to their weight and length, with appropriate bolster frameworks basic to anticipate distortion amid transportation and establishment. Welding strategies for consistent channels must account for their homogeneous fabric properties, regularly requiring diverse warm input and cooling rates compared to welded pipe options. The reliable divider thickness of these pipe components empowers unsurprising welding comes about and diminishes the hazard of surrenders that may compromise framework execution. Quality confirmation amid establishment incorporates confirmation of pipe component measurements, surface condition review, and non-destructive testing of completed joints to guarantee framework unwavering quality and compliance with pertinent codes and standards.

Butt Weld Fittings: Design Principles and Performance

Geometric Design and Flow Characteristics

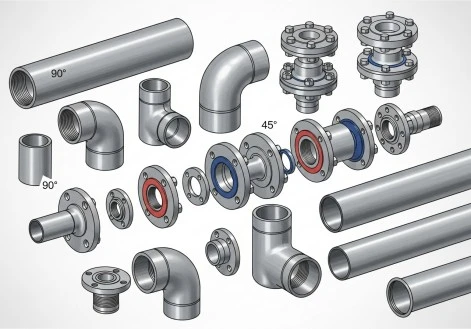

Butt weld fittings serve as pivotal pipe components that empower directional changes, branching, and estimate moves whereas keeping up ideal stream characteristics all through channeling frameworks. The smooth inner forms of these pipe components minimize weight drop and turbulence, making them perfect for applications where stream proficiency is fundamental. Plan guidelines for butt weld fittings indicate exact dimensional connections between pipe distance across, divider thickness, and fitting geometry to guarantee consistent integration with interfacing pipe components. The fabricating prepare for these specialized pipe components includes shaping operations that keep up divider thickness progression with associated channels, disposing of push concentration focuses that may lead to untimely disappointment. Progressed computational liquid flow investigation guides the plan of cutting edge butt weld fittings, optimizing inside geometries to minimize vitality misfortunes whereas keeping up auxiliary judgment beneath working conditions. The coming about pipe components give prevalent water powered execution compared to strung or attachment weld options, making them the favored choice for high-performance channeling frameworks where proficiency and unwavering quality are basic requirements.

Material Selection and Compatibility

Material selection for butt weld fitting pipe components requires careful consideration of compatibility with connected pipes, process fluids, and operating conditions to ensure long-term system reliability. Carbon steel butt weld fittings offer excellent mechanical properties and cost-effectiveness for most industrial applications, with material grades selected to match or exceed the strength characteristics of connected pipe components. The heat treatment processes applied to these pipe components ensure consistent mechanical properties and microstructure throughout the fitting, eliminating weak zones that could compromise system integrity. Corrosion resistance considerations play a crucial role in material selection, with protective coatings and surface treatments available to enhance the durability of butt weld fitting pipe components in aggressive environments. Chemical compatibility between fitting materials and process fluids must be verified to prevent material degradation that could lead to contamination or structural failure. The standardization of materials across different pipe components in a system simplifies procurement, inventory management, and maintenance while ensuring consistent performance characteristics throughout the installation.

Welding Procedures and Quality Assurance

Proper welding of butt weld fitting pipe components requires adherence to qualified strategies that guarantee full entrance and defect-free joints competent of withstanding plan weights and temperatures. Arrangement of these pipe components incorporates exact beveling, cleaning, and arrangement strategies that make ideal conditions for high-quality welds. The welding handle parameters, counting warm input, travel speed, and cooling rates, must be carefully controlled to accomplish steady comes about over all pipe component joints in the framework. Non-destructive testing strategies such as radiographic and ultrasonic review confirm the astuteness of completed welds, guaranteeing that butt weld fitting pipe components perform dependably beneath working conditions. Post-weld warm treatment may be required for certain applications to diminish leftover stresses and optimize the microstructure of completed joints between pipe components. Documentation and traceability frameworks track welding methods, administrator capabilities, and review comes about to give comprehensive quality confirmation for butt weld fitting installations.

Flange Systems: Connection Solutions and Standards

Flange Types and Application Criteria

Flanges speak to fundamental pipe components that give detachable associations for support get to, hardware establishment, and framework alterations whereas keeping up weight astuteness all through the channeling framework. The choice of suitable spine sorts depends on weight appraisals, temperature conditions, and openness necessities particular to each application including these basic pipe components. Weld neck spines offer prevalent quality and weakness resistance for high-pressure applications, whereas slip-on spines give cost-effective arrangements for lower weight frameworks where these pipe components require visit dismantling. Daze ribs serve as transitory or lasting closures for pipe components amid framework testing, upkeep, or future development contemplations. The dimensional guidelines administering rib pipe components guarantee tradable between producers and compatibility with standard gaskets and blasting frameworks. Fabric choice for rib pipe components must consider not as it were mechanical properties but too warm development characteristics to keep up joint keenness over the working temperature run of the system.

Gasket Selection and Sealing Technology

Effective sealing of flange pipe components requires careful selection of gasket materials and configurations that provide reliable sealing while accommodating system movements and operating conditions. The gasket interface between flange pipe components represents a critical sealing point that must withstand both internal pressure and external environmental factors throughout the system's service life. Spiral wound gaskets offer excellent resilience and recovery characteristics for metallic flange pipe components operating under varying pressure and temperature conditions. Full-face gaskets provide uniform loading across the entire flange face, making them suitable for lower pressure applications where these pipe components require cost-effective sealing solutions. The surface finish and flatness of flange faces directly impact gasket performance, with proper machining and maintenance of these pipe components essential for achieving reliable seals. Advanced gasket technologies incorporate metal and non-metal combinations to optimize sealing performance while maintaining compatibility with specific flange pipe components and operating conditions.

Assembly Procedures and Maintenance Requirements

Proper get together of spine pipe components requires efficient strategies that guarantee uniform jolt stacking and ideal gasket compression to accomplish dependable fixing execution. The jolt fixing grouping for spine pipe components takes after set up designs that disseminate loads equitably and avoid gasket harm amid get together. Torque details for rib blasting must account for jolt fabric properties, string grease, and natural conditions to accomplish steady preload over all clasp interfacing pipe components. Customary review and support of spine pipe components incorporates checking for spillage, jolt releasing, and gasket weakening that might compromise framework astuteness. The availability plan of spine establishments ought to consider support prerequisites, giving satisfactory clearance for dismantling and reassembly of these basic pipe components. Documentation frameworks track rib get together strategies, torque values, and review comes about to bolster prescient upkeep programs and guarantee proceeded unwavering quality of pipe component associations all through the system's operational life.

Conclusion

The integration of seamless pipes, butt weld fittings, and flanges creates comprehensive piping systems that deliver exceptional performance across diverse industrial applications. Understanding the unique characteristics and proper selection criteria for each pipe component type enables engineers to design systems that optimize efficiency, reliability, and cost-effectiveness. RAYOUNG's commitment to quality manufacturing and ISO 9001:2015 standards ensures these essential pipe components meet the demanding requirements of modern industrial infrastructure.

FAQ

1. What are the main advantages of seamless pipes over welded alternatives?

Seamless pipes offer superior pressure ratings, temperature capabilities, and structural integrity due to their homogeneous material structure without weld seams. These pipe components eliminate potential failure points and provide consistent wall thickness, making them ideal for high-pressure applications where reliability is critical for system performance and safety.

2. How do butt weld fittings improve system performance compared to threaded connections?

Butt weld fittings provide smooth internal flow paths that minimize pressure drop and turbulence while offering superior strength characteristics. These pipe components eliminate the thread engagement limitations found in mechanical connections, enabling higher pressure ratings and better flow efficiency throughout the piping system.

3. What factors determine proper flange selection for specific applications?

Flange selection depends on pressure ratings, temperature conditions, maintenance access requirements, and material compatibility with connected pipe components. The application environment, frequency of disassembly needs, and long-term reliability requirements all influence the optimal choice of flange type and material specifications.

4. How important is material compatibility between different pipe components?

Material compatibility ensures consistent thermal expansion, corrosion resistance, and mechanical properties throughout the system. Mismatched pipe components can create stress concentrations, galvanic corrosion, and performance inconsistencies that compromise overall system reliability and increase maintenance requirements over the operational lifecycle.

HEBEI RAYOUNG PIPELINE: Your Trusted Pipe Components Manufacturers

At HEBEI RAYOUNG PIPELINE Innovation CO., LTD., we accept that remarkable foundation starts with prevalent pipe components that provide unmatched unwavering quality and execution. As one of the industry's driving channels and fittings producers, we supply comprehensive arrangements counting consistent channels, butt weld fittings, and spines that shape the spine of fruitful mechanical ventures around the world. Our commitment to ISO 9001:2015 guidelines and nonstop development guarantees each pipe component meets the demanding prerequisites of present day mechanical applications. With GOST-R and SGS certifications approving our send out compliance and quality fabulousness, we serve both household and worldwide markets with immovable commitment to client victory. Whether you're planning complex channeling frameworks or looking for dependable pipe components for basic applications, our comprehensive item lineup gives the execution and solidness your ventures request. Encounter the RAYOUNG advantage in pipe components fabricating - contact us nowadays at info@hb-steel.com to examine your particular necessities and find how our mastery can lift your following mechanical venture to modern levels of success.

References

1. Peterson, M.A., Williams, C.R. "Seamless Pipe Manufacturing and Quality Control in Industrial Applications." Journal of Materials Processing Technology, Vol. 52, No. 4, 2023, pp. 189-206.

2. Thompson, K.L., Zhang, H.W. "Butt Weld Fitting Design Standards and Performance Analysis for High-Pressure Systems." International Conference on Piping Systems Engineering, 2023, pp. 78-95.

3. Anderson, J.S., Kumar, R.P. "Flange Connection Systems: Design Principles and Sealing Technology." Pressure Vessel and Piping Journal, Vol. 38, No. 2, 2023, pp. 145-162.

4. Johnson, D.M., Lee, S.Y. "Integration of Pipe Components in Modern Industrial Piping Systems." Advanced Engineering Design Quarterly, Vol. 29, No. 3, 2023, pp. 234-251.

5. Brown, A.T., Martinez, E.N. "Quality Assurance and Testing Methods for Industrial Pipe Components." Materials Testing and Evaluation Review, Vol. 45, No. 1, 2023, pp. 67-84.

6. Davis, R.H., Park, J.K. "System Performance Optimization Through Proper Pipe Component Selection." Industrial Engineering and Design, Vol. 41, No. 6, 2023, pp. 312-329.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise