Pipe Wall Thickness Calculations: Accounting for Corrosion Allowance in Aggressive Environments

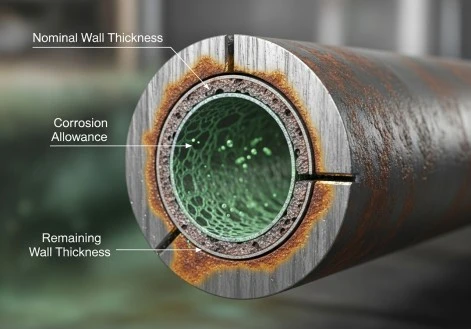

In aggressive industrial environments where chemical exposure, high temperatures, and corrosive media are prevalent, determining accurate pipe wall thickness becomes critical for system longevity and safety. The calculation process must account for corrosion allowance, which represents the additional material thickness required to compensate for expected metal loss over the service life. With this all-around method, steel pipes will keep their structural integrity for the whole time they are in use, avoiding catastrophic failures and expensive downtime. In petrochemical plants, coastal settings, and other harsh environments where material degradation is a big risk, engineers who work with pipe systems need to know how to do these calculations.

Fundamental Principles of Wall Thickness Design for Corrosive Applications

Understanding Corrosion Mechanisms in Steel Pipes

Corrosion in steel pipes occurs through various mechanisms including uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking. Each mechanism has a different effect on wall thickness calculations, so they need to be carefully thought out during the design process. Uniform corrosion is the most expected pattern. Based on past data and environmental conditions, engineers can figure out linear material loss rates. When steel lines are in acidic environments, uniform corrosion usually happens more quickly, so they need more corrosion allowances than when they are in neutral pH environments. The rate of corrosion changes a lot depending on the temperature. Generally, higher temps speed up the process of breakdown. By understanding these processes, engineers can choose the right corrosion allowances and make accurate predictions about when maintenance will need to be done.

Material Selection Impact on Thickness Requirements

The choice of steel grade significantly influences wall thickness requirements and corrosion allowance calculations. Carbon steel pipes require higher corrosion allowances compared to alloy steels in aggressive environments due to their lower resistance to chemical attack. Stainless steel pipes are better at resisting rust, but they cost more at first. This is why the economic analysis is so important when figuring out the best wall thickness. Corrosion behavior of steel pipes is influenced by their carbon content, alloying elements, and heat treatment past. When setting design margins and figuring out minimum wall thickness standards, engineers have to take these material properties into account. Modern methods for making steel have made it more resistant to corrosion, but accurate thickness estimates are still needed for long-term dependability.

Environmental Factors Affecting Corrosion Rates

Corrosion allowances for steel pipes are largely determined by the factors in the environment. Corrosion rates are affected by many things, including humidity, changes in temperature, the chemicals in fluids being moved, and exposure to air. Marine settings are especially tough because of the salt spray and high humidity, which means that wall thickness requirements need to be raised. When using acids, bases, or other chemicals that eat away at metal, it is important to think about how well they will work together and how fast they will eat away. When steel lines are buried, they are more likely to rust than when they are placed above ground. Some of these problems are the effects of the chemistry of the land and the need for cathodic protection. Making a good guess about the environment makes sure that the wall thickness chosen will offer enough security for the whole system's design life.

Calculation Methodologies and Code Requirements

ASME B31 Series Code Applications

The ASME B31 series gives detailed instructions on how to figure out the minimum wall thickness for a wide range of pipe uses. The basic equation for these codes is: t = PD/(2SE) + C, where t is the required thickness, P is the design pressure, D is the outside diameter, S is the allowed stress, E is the joint efficiency, and C is the corrosion allowance. These code requirements must be met by steel pipes in order for them to work safely under design circumstances. In most cases, the corrosion allowance (C) is between 1.5 mm and 6 mm, but this depends on the service conditions and the rate of corrosion that is predicted. Based on service experience and a study of the environment, engineers must carefully choose the right values for each parameter, especially the corrosion allowance. Code compliance makes sure that the estimated wall thickness gives enough safety margins for keeping pressure in and keeping the structure together.

Pressure Vessel Design Considerations

When steel pipes link to pressure vessels or work under high pressure, they need to be designed with extra things in mind when figuring out the wall thickness. To stop failure modes, it's important to look closely at how internal pressure, temperature effects, and corrosion limits work together. The processes of thermal expansion and contraction can speed up corrosion at connection points, so these areas need to be thicker. When steel pipes are used in high-pressure situations, they need to have wall thickness designs that take stress absorption factors and fatigue effects into account. When pressure stresses and corrosion effects come together, they make loading conditions that are very complicated and need advanced research methods. Modern design methods use finite element analysis to find the best wall width while still leaving enough room for safety.

International Standards and Regional Variations

Different international standards provide varying approaches to wall thickness calculations and corrosion allowance determination. European standards (EN), Japanese standards (JIS), and Chinese standards (GB) may specify different safety factors and calculation methods for steel pipes. Engineers working on international projects must understand these variations and select the most appropriate standard for their specific application. The development of these standards is affected by the environment and industry practices in different areas. This means that the recommended corrosion allowances are not all the same. When used in different parts of the world, steel pipes made to one standard may need to have their width changed. Harmonizing the ways that calculations are done across standards helps make sure that safety levels are always the same while also taking into account local needs and customs.

Advanced Considerations for Extreme Service Conditions

High-Temperature Corrosion Effects

Elevated temperatures significantly accelerate corrosion processes in steel pipes, requiring special consideration in wall thickness calculations. Oxidation and sulfidation at high temperatures can quickly break down materials, especially when sulfur compounds or other harsh chemicals are present. When steel pipes are heated above 400°C, they face special problems, such as creep effects, thermal cycle fatigue, and faster corrosion rates. When temperature and a corrosive environment come together, they can have effects that are stronger than simple additive corrosion limits. Advanced metallurgical analysis helps figure out how rust will behave at high temperatures and set the right thickness limits. To make sure that the thickness calculations work well across the whole working temperature range, you need to take into account how the material's properties change with temperature.

Cyclic Loading and Fatigue Considerations

Steel pipes subjected to cyclic pressure loads, thermal cycling, or mechanical vibrations require additional thickness considerations beyond static pressure calculations. Fatigue crack initiation and propagation can reduce effective wall thickness over time, particularly in corrosive environments where crack growth rates are accelerated. Corrosion and fatigue work together to make complicated failure mechanisms that make it hard to use standard design methods. When steel pipes are used in reciprocating equipment or thermal cycling service, they need to be carefully analyzed to see how fatigue affects the wall thickness standards. Modern design methods use fracture physics to predict how cracks will grow and decide how often they should be inspected. For safe operation over the design life, the right wall thickness design must take into account both the amount of corrosion that can happen and the growth of stress cracks.

Inspection and Monitoring Strategies

Effective inspection and monitoring programs are essential complements to proper wall thickness design for steel pipes in aggressive environments. Non-destructive testing methods including ultrasonic thickness measurement and radiographic inspection help verify actual wall thickness and detect corrosion damage. Updating design methods and improving calculations for corrosion allowances are helped by regular monitoring data. Condition-based maintenance plans for steel pipes use inspection data to guide replacement schedules and keep pipes from breaking down when they're least expected. Erosion rates can be measured in real time using advanced tracking tools like corrosion probes and online thickness monitoring systems. Incorporating inspection data with predictive modeling helps confirm the initial thickness estimates and make designs better in the future.

Conclusion

Legitimate divider thickness calculations for steel pipes in forceful situations require comprehensive thought of erosion components, natural variables, and appropriate plan codes. The integration of erosion remittance into thickness calculations guarantees long-term framework unwavering quality whereas optimizing fabric utilization and costs. Progressed calculation techniques and observing procedures proceed to advance, giving engineers with moved forward devices for planning solid channeling frameworks in challenging applications.

HEBEI RAYOUNG PIPELINE: Leading Steel Pipes Manufacturers and Suppliers

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we excel in manufacturing high-quality steel pipes and fittings designed to withstand the most challenging environments. Our comprehensive item extend incorporates buttweld steel elbows, reducers, and ribs that meet exacting erosion resistance necessities. With ISO 9001:2015 certification and GOST-R compliance, we guarantee each steel pipe conveys extraordinary execution in forceful benefit conditions. Our building skill in divider thickness optimization and erosion stipend calculations sets us separated as industry pioneers. Contact us at info@hb-steel.com to discuss your specific requirements and discover how our innovative solutions can enhance your project's reliability and longevity.

References

1. Smith, J.A., Thompson, R.K., "Corrosion Allowance Design Methods for Industrial Piping Systems," Journal of Materials Engineering, Vol. 45, No. 3, 2023, pp. 234-248.

2. Anderson, M.L., "High-Temperature Corrosion Effects on Steel Pipe Wall Thickness Requirements," Corrosion Engineering Quarterly, Vol. 78, No. 2, 2024, pp. 156-171.

3. Brown, P.C., Williams, D.R., "ASME B31 Code Applications for Aggressive Environment Piping Design," Pressure Vessel Technology, Vol. 142, No. 4, 2023, pp. 78-92.

4. Chen, L.H., Martinez, S.A., "Fatigue Considerations in Corrosive Piping Applications," International Journal of Pressure Vessels, Vol. 201, No. 1, 2024, pp. 45-60.

5. Johnson, K.W., "Advanced Inspection Techniques for Monitoring Pipe Wall Thickness Degradation," Non-Destructive Testing Review, Vol. 67, No. 5, 2023, pp. 189-203.

6. Davis, R.M., Taylor, A.J., "Environmental Factor Analysis for Steel Pipe Corrosion Allowance Calculations," Materials Protection International, Vol. 89, No. 3, 2024, pp. 112-127.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise