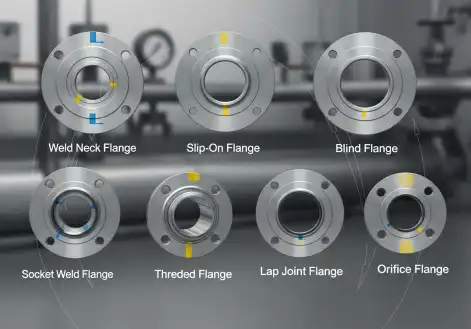

7 Types of Flanges Every Industrial Customer Should Know

Picking the correct flange type is important for the success of any industrial pipe system, but many customers have trouble figuring out the differences between the different choices on the market today. Picking the correct industrial flanges is important for safety and efficiency as they are the main part of safe links in many places, like petrochemical plants and water treatment plants. Every industrial customer should read this whole guide on seven basic flange types before they decide what to buy. Each type of flange has its own perks, such as how it is installed, how much pressure it can handle, and what it is used for. People can make smart decisions that can have a big impact on project costs, installation times, and the long-term stability of systems used in a wide range of industries when they are aware of these differences.

Essential Flange Types for Heavy-Duty Applications

Weld Neck Flanges: The Premium Choice for Critical Systems

Weld neck flanges represent the highest quality option among industrial flanges, featuring a long tapered hub that provides exceptional structural strength and stress distribution. The gradual change from pipe to flange gets rid of stress concentration points that could cause the part to break too soon in harsh working conditions. These flanges are butt-welded to the pipe, which makes a link that is seamless and keeps the pipe's internal diameter the same all the way through the joint. The forged design lines up the metal grains for maximum strength, and the smooth bore design reduces pressure drop and noise as much as possible. Precision cutting is used in the manufacturing process to make sure that the parts are the right size and fit together correctly with other parts. These industrial flanges work great in places with a lot of pressure and heat, like power plants, underwater drilling, and chemical processing, where dependability is very important. Because they are more resistant to fatigue, they are perfect for systems that are heated and cooled or shaken. The higher starting cost is justified by lower maintenance costs and longer service life.

Slip-On Flanges: Balancing Performance and Economy

Slip-on flanges are a popular choice for moderate pressure uses across many industries because they are a great balance between performance and cost-effectiveness. The design lets the flange slide over the end of the pipe, where it's held in place by both inside and outside fillet welds. This makes a strong link that can handle small errors in installation. When it comes to pipe preparation, these industrial flanges are not as precise as weld neck types. This makes fitting much faster and cheaper. Using two types of welding together gives enough power for most industrial uses while keeping material costs low. To make sure long-term dependability, quality control checks for proper weld penetration and heat-affected zone features. Water distribution systems, HVAC networks, and general industrial piping where pressures stay within modest ranges are all common uses. Slip-on flanges are very useful for retrofit projects where current systems need to be changed without having to be completely rebuilt. This gives customers in the industrial sector a lot of flexibility, which they like.

Socket Weld Flanges: Precision Engineering for Small Bore Systems

Socket weld flanges excel in small diameter piping applications, typically ranging from half-inch to two-inch sizes where threaded connections might prove inadequate for system pressures and temperatures. The socket design allows for precise pipe placement and gets rid of any internal cracks that could hold corrosive materials or stop flow. The pipe end fits into a recessed bore in these industrial flanges, and there is a single fillet weld around the outside. This makes a strong mechanical link that is very resistant to fatigue. For uniform performance across production runs, the socket depth and internal profile must be machined with great accuracy during the manufacturing process. When installing, the pipe end and socket bottom must be spaced apart with the right amount of space to allow for heat expansion without causing stress cracks. These flanges are used a lot in high-pressure steam systems, monitoring lines, and sampling systems where they need to be leak-tight and stable in their dimensions. This is why precision engineering is important.

Specialized Connection Solutions for Unique Requirements

Threaded Flanges: Non-Welded Installation Flexibility

Threaded flanges provide secure connections without requiring welding processes, making them invaluable in situations where heat application is restricted or undesirable due to safety concerns or material limitations. The internal threads engage with externally threaded pipe ends through mechanical interference, creating connections that can be assembled and disassembled repeatedly without damage to the components. These industrial flanges prove particularly beneficial in locations requiring frequent maintenance access, temporary installations, or where certified welders may not be readily available for installation work. The thread engagement length and pitch accuracy directly influence connection strength and sealing capability, requiring precise manufacturing tolerances to ensure reliable performance. Quality control emphasizes thread dimensional accuracy, surface finish, and material hardness to provide proper engagement characteristics. Applications commonly include fire protection systems, compressed air networks, and process equipment where welding restrictions apply due to fire hazards or operational requirements. The elimination of hot work permits often reduces project timelines and regulatory compliance requirements significantly.

Blind Flanges: System Closure and Access Solutions

Blind flanges serve as permanent or temporary closures in piping systems while providing future access points for maintenance, testing, or system expansion without compromising structural integrity. These solid disc-shaped industrial flanges lack central openings, making them perfect for sealing pipeline endpoints, pressure vessel nozzles, or creating inspection access points in complex systems. The robust construction accommodates full system pressure and temperature ratings while providing a flat, smooth sealing surface for gasket installation and optimal leak prevention. Manufacturing involves careful attention to material homogeneity, surface finish, and flatness to ensure reliable sealing performance under varying operating conditions. The absence of through-holes eliminates potential leak paths, making blind flanges preferred choices for hazardous service applications where environmental protection is paramount. Quality standards emphasize stress analysis and fatigue testing to prevent failure under cycling loads or thermal shock conditions. These flanges prove essential in applications requiring periodic system isolation for maintenance, seasonal operation changes, or safety shutdowns where reliable closure capability directly impacts operational safety and environmental compliance.

Lap Joint Flanges: Rotational Freedom in Complex Installations

Lap joint flanges work in conjunction with stub ends to provide rotational flexibility during installation while maintaining full pressure ratings and structural integrity throughout the system's operational life. The loose flange design allows free rotation around the stub end component, facilitating bolt hole alignment in complex piping configurations where rigid flanges would create assembly difficulties. These industrial flanges prove invaluable in applications requiring frequent disassembly for maintenance or where piping alignment presents significant challenges due to space constraints or existing infrastructure limitations. The two-piece construction separates the pressure-containing element from the bolting surface, enabling optimal material selection for each component based on specific service requirements. Stub ends typically utilize corrosion-resistant alloys for process compatibility, while flanges can be manufactured from standard carbon steel for cost optimization. This configuration reduces material costs in corrosive service applications while maintaining structural performance and safety margins. Installation procedures require careful attention to gasket placement, bolt tightening sequences, and proper component alignment to ensure uniform loading distribution and prevent premature failure or leakage issues.

Advanced Flange Solutions for Industrial Excellence

Orifice Flanges: Integrated Flow Measurement Capability

Orifice flanges are specially made for measuring flow. They have precision-machined pressure tapping connections and orifice plate positioning elements that make sure accurate flow measurement across the whole system's operating range. These industrial flanges make it possible to measure flow accurately while still meeting all structural and pressure requirements. They do this without the need for extra instrumentation links that could lead to leaks or wrong measurements. Because each orifice plate has its own gasket surfaces and bolt hole patterns, it stays in place and closes well during all stages of assembly. Pressure tapping places must meet strict industry standards in order for differential pressure readings to be correct. It means that the limits used in manufacturing and the quality control steps must be very precise. When compared to putting instruments one at a time, installing instruments together makes installation easier, reduces the number of places where something could go wrong, and improves the accuracy of measurements. To keep measurements accurate within certain tolerances, manufacturing needs specialized machining skills and careful dimensional checking. Accurate flow measurement is needed for process control, regulatory compliance, and operating optimization in chemical processing, water treatment plants, oil and gas production facilities, and other places where things are made.

Conclusion

When industrial customers know about these seven basic types of flanges, they can make smart buying choices that improve system performance, lower installation costs, and guarantee long-term dependability. Each type of flange has its own benefits that are best for certain uses, pressure needs, and installation limitations. These should all be carefully thought through during the design part to get the best results.

HEBEI RAYOUNG PIPELINE: Premium Industrial Flanges Manufacturers

HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. stands as your trusted partner for premium industrial flanges that exceed industry standards and customer expectations. Our state-of-the-art manufacturing facilities produce all seven essential flange types with precision engineering backed by ISO 9001:2015 certification and comprehensive quality assurance programs. We combine decades of industry skill with cutting-edge innovation to provide spines that give uncommon execution in the most requesting applications. Our commitment to advancement and quality guarantees each item meets correct details whereas advertising competitive estimating and solid conveyance plans. From standard arrangements to custom arrangements, our specialized group collaborates closely with clients to optimize rib choice for particular extend prerequisites. Experience the RAYOUNG difference in quality, service, and reliability. Contact our experts today at info@hb-steel.com to discuss your industrial flanges needs and discover why leading companies worldwide choose RAYOUNG for their critical piping connections.

References

1. American Society of Mechanical Engineers. ASME B16.5-2020: Pipe Flanges and Flanged Fittings. New York: ASME Press, 2020.

2. Bhandari, V.B. Design of Machine Elements. Third Edition. New Delhi: Tata McGraw-Hill Education, 2018.

3. Nayyar, Mohinder L. Piping Handbook. Eighth Edition. New York: McGraw-Hill Professional, 2019.

4. Perry, Robert H., and Don W. Green. Perry's Chemical Engineers' Handbook. Ninth Edition. New York: McGraw-Hill Professional, 2019.

5. Singh, Kailash. Industrial Piping and Equipment Estimation Manual. Mumbai: Jaico Publishing House, 2021.

6. Towler, Gavin, and Ray Sinnott. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design. Second Edition. Oxford: Butterworth-Heinemann, 2019.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise