Pipe Flange Leakage Testing: Methods and Inspection Standards

Pipe flange leakage testing is an important part of industrial pipeline integrity management. It includes methodical ways to find and stop fluid or gas from escaping at connection points without permission. Effective flange leak testing procedures protect working efficiency and make sure that strict safety rules are followed. Industrial sites that know about thorough testing methods can keep their systems running at their best throughout their entire working lifetime, with less downtime and lower maintenance costs.

Understanding Flange Leakage and Its Implications

Common Causes of Flange Leakage

Fluid or gas leaks from industrial pipe junction connections without intention. Gasket wear and tear, particularly when covering materials break down from chemicals or high temperatures, is the major reason. When installation isn't straight, force is unevenly distributed over the flange surfaces, weakening the closing mechanisms.

Leaks develop due to operating pressures. Repetitive pressure changes degrade bolt links and sealing materials. Thermal expansion and contraction generate microscopic spaces that become leaks, worsening these issues. Not following bolt pressure requirements during assembly might result in insufficient compression force, preventing adequate sealing surface contact.

Safety and Financial Consequences

Leaks in flanges that aren't found can be very dangerous in industrial settings. Dangerous chemical spills put people's health at risk and pollute the environment, which is a liability. Explosive gas buildups pose huge dangers that can damage the whole building and lead to fines from regulators.

The effects on the economy go beyond the cost of repairs. When production stops for emergency leak fixes, it throws off working plans and responsibilities to meet contracts. When safety problems happen, insurance rates go up a lot, and government fines add to the cost of doing business. When it comes to cost-effectiveness, proactive leak discovery techniques beat reactive upkeep methods.

Regulatory Compliance Requirements

Modern factories have to follow strict rules and regulations that require them to regularly check for leaks. According to guidelines set by the Environmental Protection Agency, certain process uses need to have recorded review intervals. The Occupational Safety and Health Administration sets limits on how much contact workers can have, which must be met by taking certain steps to stop leaks.

International standards groups offer complete plans for putting systematic leak discovery into action. These standards make sure that flange leakage testing methods are the same across all businesses around the world and make it easier to follow the rules for government audits. Inspection records that are written down are very important as proof during regulatory reviews and insurance claim processes.

Comprehensive Overview of Flange Leakage Testing Methods

Traditional Pressure Testing Approaches

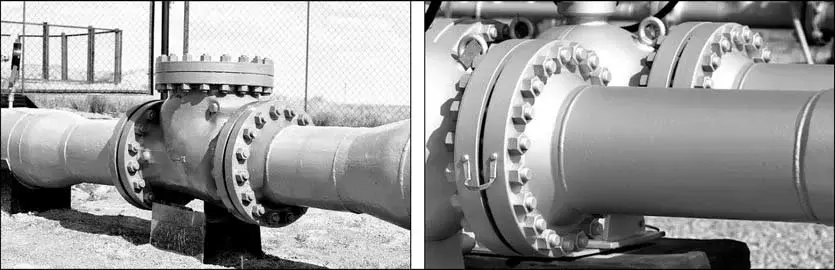

Hydrostatic testing is still the best approach to ensure a plate is solid when utilized. This technology fills pipes with water at high pressures. Air loss was absent at specific times, proving that all joint linkages were sealed.

When water pollution might damage process equipment or product quality, pneumatic testing is best. The testing medium, pressurized air or nitrogen, allows fast pressure and system drain. But pneumatic technologies require higher safety standards since compressed gases retain deadly energy if not released.

Visual inspection helps pressure testing detect leaks early. Professionals check for darkening, rust patterns, or solid layers on flanges to indicate long-term seepage. Digital imaging captures original conditions and tracks deterioration between examinations.

Advanced Non-Destructive Testing Technologies

Ultrasonic leak detection technology transforms repair by discovering microscopic leaks before they become visible. High-frequency sound sensors detect turbulent gas flow patterns generated by flange joint pressure variations. Testing may continue without disrupting production using this strategy.

Helium leak detection is sensitive and may be utilized in severe circumstances requiring strong sealing proof. Helium tracer gas may pass through invisible holes. Mass spectrometer monitors reliably evaluate leakage rates in nuclear, pharmaceutical, and military contexts.

Thermal imaging devices detect fluid- or gas-departure-related temperature variations. Evaporative cooling causes temperature variations near leaky flanges. However, infrared cameras can swiftly scan extensive pipe networks and identify sites for further research.

Modern Sensor Monitoring Systems

With continuous tracking technologies, asset management techniques can move from reactive repair to predictive asset management. Wireless sensor networks let you find leaks in real time and set off automatic alarms. Pressure, temperature, and sound signals are just some of the things that these sites measure at the same time.

Integrating smart sensors with plant control systems lets protocols start responding right away when leak detection levels are met. Collecting historical data helps with identifying trends and planning ahead for repair. Remote tracking lets experts who aren't on-site look at how the system is working and suggest ways to fix problems.

Flange Leakage Testing Standards and Inspection Procedures

International Standard Organizations

Standards set by the American Petroleum Institute include detailed instructions for managing the quality of flanges in the oil and gas businesses. API 570 gives detailed inspection routines for pipe systems that are already in use. These include risk-based inspection methods that find the best flange leakage testing rates based on how the system is being used.

The American Society of Mechanical Engineers sets the standards for how pressure vessels and pipes should be designed, which has a direct effect on how well flanges should work. The ASME B31.3 process pipe guidelines say how often tests should be done and what kind of leaks are allowed in different working situations. These rules make sure that testing procedures are followed the same way in all of a facility's activities.

Frameworks from the International Organization for Standardization (ISO) provide testing methods that are accepted all over the world. This makes it easier for countries to trade and share technology. The ISO 15848 standard sets standard measurement methods and acceptance criteria for checking stray emissions in valves and flanges.

Pre-Test Safety Preparations

To protect people and equipment, thorough safety measures come before all leak discovery activities. Lockout/tagout processes make sure that the system is completely shut down before testing starts. Atmospheric tracking makes sure that working conditions are safe around process fluids that could be harmful.

Personal safety equipment needs change depending on the properties of the process media and the way the tests are done. When checking systems that contain poisonous or suffocating fumes, it is important to wear respiratory protection. The emergency reaction methods cover possible situations where people could be exposed and how to evacuate.

Calibration checking of testing equipment makes sure that measurements are correct and that the equipment is in line with regulations. Calibration papers, user training, and records of machine upkeep are some of the things that need to be documented. Quality assurance rules make sure that testing methods and how results are interpreted are correct.

Documentation and Record Management

Structured paperwork systems help with making decisions about asset management and following the rules. Inspection records include thorough results, picture proof, and suggestions for what needs to be done to fix the problem. Trending research finds trends of wear and tear that help optimize repair schedules.

Database management systems group inspection records so that they are easier to find during insurance reviews or checks by the government. When you keep records electronically, you can compare them with working factors and repair reports. Standardized reporting forms make sure that all inspection teams and sites of a building follow the same rules.

Selecting the Right Flange Leakage Testing Equipment and Services

Equipment Selection Criteria

Application-specific leak-detecting limits are used to choose the right tools based on sensitivity requirements. For process safety uses, sensitivity levels need to be higher than for general utility systems. The cost-benefit study checks the powers of the tools against the needs of the business and the available funds.

Compatibility checks make sure that testing equipment works well with the pipes and materials that are already in place. For testing protocols to work correctly with ANSI, DIN, and JIS standard flanges, adapters must be set up in a certain way. For field uses, portable equipment gives you more options, while fixed systems let you keep an eye on things all the time.

The design of the user interface affects how quickly and correctly the operator can understand the results. Intuitive control systems cut down on the need for training while also lowering the chance of user mistake. Digital screens and the ability to log data improve the quality of documents and the usefulness of trend analysis.

Professional Service Provider Selection

Service provider qualifications show that they know how to do certain types of tests and follow safety rules. Certified worker skills make sure that the equipment is used correctly and that the results are understood correctly. Having worked with similar apps in the past shortens the learning curve and speeds up testing.

With local assistance, reaction times for pressing testing needs or equipment repair needs are kept to a minimum. Regional service centers make it easy to get specific tools and technology know-how quickly. Emergency reaction availability helps with important system reviews when systems shut down without warning.

RAYOUNG knows a lot about industrial pipe fittings and can help with all kinds of leak detection problems with their full flange integrity solutions. Our standard ANSI, DIN, and JIS flanges have precise CNC-machined sealing surfaces that make tests more accurate and improve the trustworthiness of their long-term performance. The RF, FF, and RTJ face choices that can be used for a variety of high-pressure tasks while still providing the same level of closing.

As part of our dedication to quality excellence, all of our flange parts can be fully tracked back to the MTC. This makes sure that they are made in accordance with the material specs and flange leakage testing requirements. Hot-dip galvanizing choices make things more resistant to rust, which extends their useful life in harsh environments. These advanced manufacturing skills help find leaks more accurately while lowering the number of times they need to be fixed.

Conclusion

Effective methods for checking for flange leaks are important parts of workplace safety and reliability plans that cover the whole business. Understanding the different testing methods helps you make smart choices about what tools to buy and how often to check it. Following the rules makes sure that regulations are followed and protects the safety of people and the surroundings. Long-term practical benefits come from spending money on the right testing tools and skilled service providers, like less downtime and lower repair costs.

Frequently Asked Questions

1. How often should flange leak testing be performed?

Testing frequency depends on several critical factors, including process media characteristics, operating pressure and temperature conditions, and regulatory requirements. High-risk applications involving hazardous chemicals typically require monthly or quarterly inspections. General utility systems may operate safely with annual testing cycles. Risk-based inspection methodologies optimize testing schedules by prioritizing high-consequence failure locations.

2. Can leak testing be performed without system shutdown?

Many modern leak detection techniques enable testing during normal operations without production interruptions. Ultrasonic detection and thermal imaging provide non-invasive screening capabilities suitable for routine monitoring. However, definitive pressure testing typically requires system isolation and may necessitate planned shutdown coordination.

3. What leak detection sensitivity is required for different applications?

Sensitivity requirements vary significantly based on process safety considerations and regulatory standards. Environmental applications may require detection thresholds below 10 ppm, while general industrial systems accept higher levels. Critical applications such as nuclear or aerospace often demand helium leak testing with sensitivity levels approaching 10^-10 standard cubic centimeters per second.

Partner with RAYOUNG for Superior Flange Solutions

RAYOUNG offers complete industrial pipe fitting solutions that make it easier to find leaks and make your building more reliable. Our precisely designed flanges support effective testing methods and require minimal upkeep over the course of their useful life. Get in touch with our technical experts at info@hb-steel.com to talk about unique flange leakage testing options that will help your system work better and meet legal requirements. Our skilled staff can help you choose the right flange combinations and testing methods for your unique needs. Find out how our advanced manufacturing skills and quality standards can help the safety and dependability goals of your business.

References

1. American Petroleum Institute, "API 570 Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping Systems," Fourth Edition, 2016.

2. American Society of Mechanical Engineers, "ASME B31.3 Process Piping: ASME Code for Pressure Piping," 2018 Edition.

3. International Organization for Standardization, "ISO 15848-1 Industrial valves—Measurement, test, and qualification procedures for fugitive emissions," Part 1: Classification system and qualification procedures for type testing of valves, 2015.

4. Environmental Protection Agency, "Method 21 - Determination of Volatile Organic Compound Leaks," Code of Federal Regulations, Title 40, Part 60, Appendix A-7, 2017.

5. British Standards Institution, "BS EN 1591-1:2013 Flanges and their joints—Design rules for gasketed circular flange connections," European Standard, 2013.

6. Occupational Safety and Health Administration, "OSHA Technical Manual Section IV: Chapter 2—Petroleum Refinery Process Safety Management," U.S. Department of Labor, 2019.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise