To ensure safe and effective performance, installing a weld neck flange on stainless steel pipe must be performed with care, using the right tools, and following industry standards. A weld neck flange spreads stress to the pipe, making the area at the base of the flange less highly stressed. Because of this, weld neck flanges can be used in the oil and gas business. To get the best joint stability, the installation process includes careful planning, exact welding, and a lot of quality checks.

Understanding Weld Neck Flanges and Their Role in Stainless Steel Piping

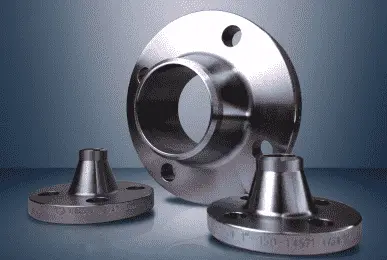

Weld neck flanges are a special kind of pipe part that is designed to operate efficiently in stainless steel pipe systems. These flanges have a unique long curved hub that gradually changes from the thickness of the pipe wall to the thickness of the flange. This makes the joining point very strong.

Design Characteristics and Stress Distribution

Weld neck flanges are better at distributing stress than other types of flanges because of their unique curved shape. The slow change successfully moves mechanical stresses away from the weld joint, lowering the risk of stress buildup factors that could cause the joint to fail too soon. In high-pressure situations, where managing stress is key to keeping the system safe and reliable, this design feature becomes even more important.

Material Selection and Corrosion Resistance

304, 316, and duplex stainless steel alloys are all types of stainless steel that are often used for weld neck flanges. Grade 304 is very good at resisting corrosion in most conditions, while grade 316 is better at resisting salt corrosion. Duplex stainless steels are great for chemical handling and marine uses because they are both strong and resistant to corrosion. In toxic conditions, the choice of material has a direct effect on the service life and upkeep needs.

These flanges are very important in industries like petrochemical processing, power generation, and offshore oil platforms because they can stay strong in harsh conditions. Weld neck flanges are the best choice for important uses where failure could have major safety and cost effects because they are both strong and resistant to corrosion.

Preparing for Installation: Dimensions, Materials, and Tools

Preparation is the most important part of installing a weld neck flange correctly. To get reliable, code-compliant results in this phase, you need to pay close attention to checking the dimensions, making sure the materials are compatible, and choosing the right tools.

Dimensional Verification and Standards Compliance

For accurate dimensional verification, check the outer diameter of the flange, the width of the bolt circle, the thickness, and the pressure number against standards like ASME B16.5. To make sure the pipe fits and lines up correctly, the flange hole must exactly match the pipe's outer diameter. Design rules say that pressure values must be higher than the working pressures of the system with the right safety factors.

Essential Tools and Equipment

Professional work needs special tools to get the same effects every time. For proper completion, you must have the following tools:

- Welding Tools: TIG or MIG welders that can work with stainless steel, along with the right filling metals and protective gases for the best penetration and rust protection.

- Measurement Tools: Accurate tools, gap gauges, and alignment fixtures are used to make sure that the measurements are correct during the fitting process.

- Preparation and cutting tools, including pipe beveling machines, drills, and cleaning agents, are used to prepare areas for welding.

- Safety Gear: To keep the workplace safe, there are welding hats, protective clothes, air systems, and fire safety gear.

With these tools, techs can do tasks that meet strict quality standards and safety standards. Weld quality and measurement accuracy are directly affected by how well the tools are chosen and calibrated.

Step-by-Step Guide to Installing a Weld Neck Flange on Stainless Steel Pipe

To get reliable, long-lasting links, the installation process needs each step to be done in a methodical way. Paying close attention to every step saves money on rework and makes sure the method works right.

Surface Preparation and Pipe Beveling

To make the best weld joint shape, start the fitting by beveling the pipe end the right way. Depending on the thickness of the wall and the requirements of the welding process, the bevel angle is usually between 30 and 37.5 degrees. Thoroughly clean all areas to get rid of dirt, oils, and rust layers that could lower the quality of the weld. To get the amount of cleanliness you need, use the right chemicals and mechanical cleaning methods.

Alignment and Tack Welding

Place the weld neck flange on the pipe end, making sure it is lined up correctly and that there are sufficient root gaps as required by the welding process. During tack welding, keep things in place with alignment tools or pins. Put tack welds in key spots around the edge to hold the flange in place while letting it expand during the full welding process. After each tack weld, check the alignment to avoid problems with warping.

Complete Welding and Post-Weld Treatment

Follow the correct welding steps for stainless steel uses and complete the whole welding process. For important jobs, TIG welding usually gives you better control and quality, while MIG welding might make you more productive for less important jobs. Keep the interpass temperatures correct and use the right filler metals to get the mechanical qualities and rust protection you need.

After the work is done, it should be carefully checked using nondestructive testing methods such as liquid penetrant testing and, where required by code, radiographic or ultrasonic examination. Pressure testing proves that the joint can safely hold system stresses, which means that the fitting was completed successfully.

Comparing Weld Neck Flanges with Other Flange Types for Stainless Steel Pipes

After learning about the pros and cons of the different types of flanges, you can make smart buying choices based on your application needs and your budget.

Performance Comparison Analysis

When it comes to strength and stress resistance, weld neck flanges are better than slip-on flanges, which are easier to install but not as strong. When it comes to smaller pipe sizes, socket weld flanges are strong, but their crevice design can increase the risk of crevice corrosion in stainless steel applications. While threaded joints make upkeep easier, they can only handle a certain amount of pressure and could be a leaky path.

Cost-Benefit Considerations

Although weld neck flanges cost more in materials and work to install at first, they are more valuable in the long run because they need less upkeep and last longer. The way the stress is distributed keeps fatigue breakdowns to a minimum, which prevents costly unexpected shutdowns. This economic benefit is especially important in key process uses where dependability has a direct effect on profits.

Best Practices and Common Pitfalls in Weld Neck Flange Installation

Using tried-and-true best practices and avoiding common installation mistakes will make sure that the quality and dependability of all projects are the same. Knowing from experience helps keep you from making mistakes that could cost a lot of money and damage the system.

Critical Success Factors

Attention to material tracking, welding process training, and worker approval are always shown by setups that go well. Keeping detailed records throughout the process helps with quality control and meeting legal standards. Controlling the temperature while welding stops warping and makes sure that the finished joint has the right metallic qualities.

Maintenance and Inspection Requirements

Set up regular review times to check on the flanges and find issues before they get worse. If you look at it, you can tell if there is surface rust, mechanical damage, or worn seals that need to be fixed. Making sure that the nuts' strength is checked often keeps the closing force at the right level over time. Preventative maintenance systems work better and find the best times to fix things when check data is kept.

RAYOUNG: Your Trusted Weld Neck Flange Manufacturer

RAYOUNG is a leading manufacturer of high-quality weld neck flanges and complete pipe systems for use in factories all over the world. Our large selection of products includes a wide range of industrial pipe fittings, butt-weld steel elbows, steel reducers, and flanges that make sure all design requirements are met.

As a reliable steel pipe and fitting provider, As a reliable steel pipe and fitting provider, RAYOUNG always serves markets in Southeast Asia and around the world with goods that have GOST-R and SGS approvals to show that they are safe for export and meet quality standards. Our steel pipe fittings and steel pipes offer top-notch performance, safety features, and long-lasting sturdiness for a wide range of uses, from homes and businesses to factories and industrial sites.

RAYOUNG is certified to ISO 9001:2015, which means they know how important it is to provide steady quality and new ideas in all of their work. We use advanced quality control methods in our production processes to make sure that every weld neck flange meets the highest international standards. Our fittings support key flow systems with accuracy and dependability that industry users count on for their most important uses. They work with water and gas lines.

Conclusion

The process of installing weld neck flanges on stainless steel pipe systems requires careful attention to detail in terms of planning, carrying out, and evaluating the quality of the installation. Due to the fact that these flanges are so effective at distributing stress, they are ideal for usage in demanding settings such as the oil and gas industry as well as other significant areas. In order to achieve success, it is necessary to choose the appropriate materials, adhere to the appropriate procedures, and implement comprehensive quality control systems. Weld neck flange configurations that are executed correctly provide dependable, long-term service that, over time, not only pays for itself via reduced maintenance expenses but also improves the overall efficiency of the system.

Frequently Asked Questions

Q1: What pressure rating should I select for my weld neck flange application?

A: Selecting the correct pressure rating requires evaluating maximum system operating pressure, temperature conditions, and applicable design codes. Choose a rating that exceeds operating pressure by the safety factor specified in your design standard, typically 1.5 to 4 times depending on the application and code requirements.

Q2: Can weld neck flanges be reused after removal from a piping system?

A: Weld neck flanges are generally not recommended for reuse after removal due to potential weld integrity compromise and stress concentration changes. The cutting and removal process typically damages the flange structure, making replacement the safer option for maintaining system reliability.

Q3: What welding considerations are specific to stainless steel weld neck flanges?

A: Stainless steel welding requires specific techniques, including proper heat input control, appropriate filler metals, and post-weld cleaning to maintain corrosion resistance. Use low-carbon filler metals, control interpass temperatures, and avoid contamination from carbon steel tools or surfaces that could compromise corrosion resistance.

Partner with RAYOUNG for Superior Weld Neck Flange Solutions

RAYOUNG delivers comprehensive technical support and premium weld neck flange solutions tailored to your specific industrial requirements. Our experienced engineering team provides expert consultation on flange selection, installation guidance, and custom procurement solutions that minimize project risk while ensuring compliance with international standards. Access our extensive inventory of certified stainless steel weld neck flanges backed by comprehensive quality documentation and testing certifications. Contact us at info@hb-steel.com to request detailed quotations, technical specifications, or sample products that demonstrate our commitment to excellence as your trusted weld neck flange supplier.

References

1. American Society of Mechanical Engineers. "ASME B31.3 Process Piping Code." New York: ASME Press, 2020.

2. Bickford, John H. "Gaskets and Gasketed Joints, Second Edition." New York: Marcel Dekker, 1998.

3. Cunningham, John P. "Understanding Pipe Stress Analysis." Houston: Gulf Professional Publishing, 2018.

4. Harvey, John F. "Theory and Design of Pressure Vessels." New York: Van Nostrand Reinhold, 1991.

5. Paulin Research Group. "Handbook of Bolted Connections." Montreal: Paulin Research Group Publications, 2017.

6. Rothwell, A.B. "Optimization of Piping Systems." London: Mechanical Engineering Publications, 1995.