Properly installing pipe flanges is crucial to keeping workers safe and ensuring smooth operations. There are more problems than just leaks when engineers and supply managers forget to do important steps during installation. Downtime costs a lot of money, creates safety risks, and makes it difficult to follow the rules. This will help the system stay stable, pipe flange installation keep project costs low, and keep everyone safe on the job. Just remember to stay away from these common pipe flange installation mistakes. This full guide talks about the most common mistakes that people make when installing pipe systems on industrial projects and gives engineers, procurement managers, dealers, and OEM clients who need reliable pipe system performance real-world answers.

Understanding Common Pipe Flange Installation Mistakes

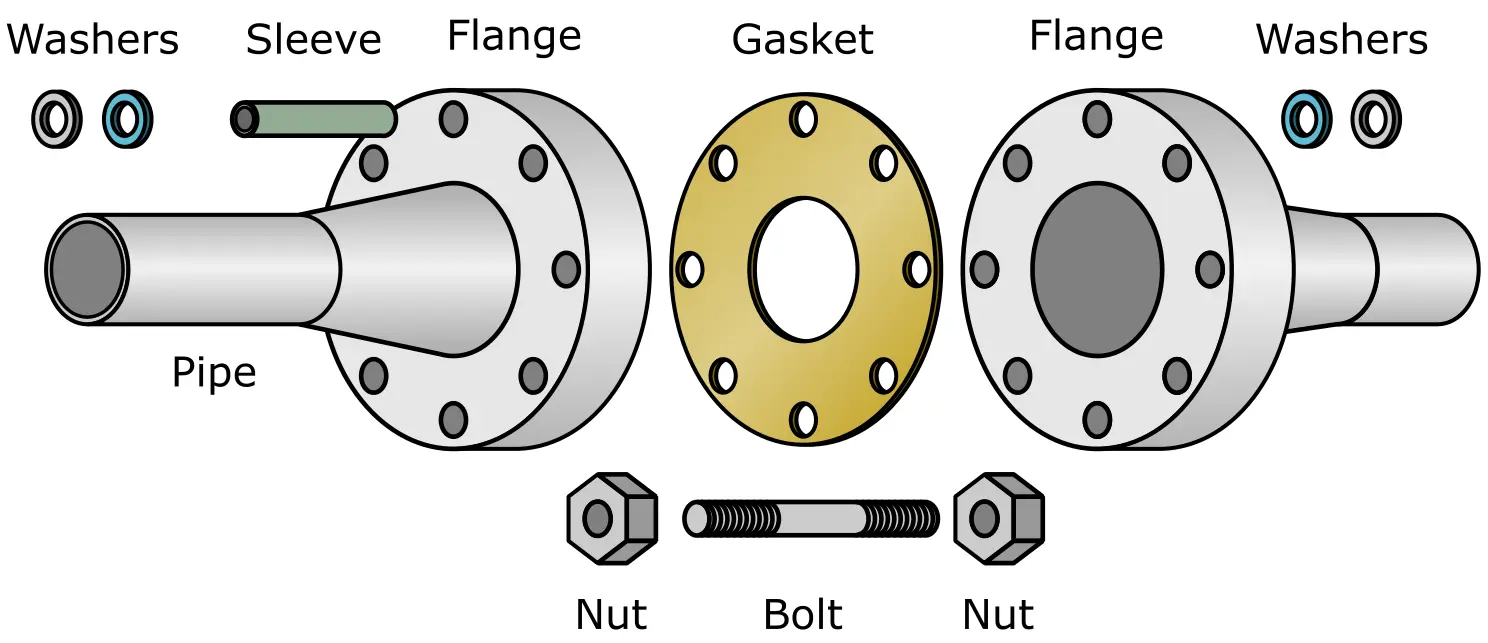

Putting on a pipe flange requires several important steps, such as making sure the flange is lined up properly, putting the gaskets in the right place, and tightening the bolts in a certain order. For each step, you need to pay close attention to the details and follow the rules set by groups like ANSI, DIN, and JIS.

Flange Misalignment Issues

It is very usual for fitting mistakes to be out of alignment, which means that the faces of the flanges don't sit parallel or concentric. The stress on the gasket surface is spread out widely because of this mistake. This makes the seal fail before it should. A difference of just 0.5 mm can cut a gasket's life by as much as 40%, according to a study. It's even worse when there is a lot of pressure, because precise CNC-machined sealing areas are needed to keep the seal's integrity.

Incorrect Bolt Tightening Procedures

If bolt torque is not applied properly, it can lead to uneven gasket compression and stress concentrations, reducing the flange's sealing performance and stability. When over-tightened, the seal materials can crack, and the sides of the flange may bend. Not being tight enough can lead to leaks. Industry standards say that calibrated torque wrenches must be used for cross-pattern tightening to make sure that the preload is the same in all bolt places.

Gasket Selection and Placement Errors

The sealing performance is greatly affected by choosing the wrong gasket materials or face types. Different types of joints, like ring-type joint (RTJ), raised face (RF), and flat face (FF), need different types of gaskets and ways to place them. When spiral wound gaskets are used on flat face flanges or when gaskets are placed outside of bolt circles, it can lead to improper sealing, causing leakage or failure of the flange connection.

Root Causes Behind Frequent Installation Failures

Installation problems don't usually happen by themselves; they're usually caused by problems with how the project is being run and how resources are being used. When buying teams know these root causes, they can take preventative steps that stop problems from happening again.

Inadequate Tooling and Equipment

A lot of repair teams use old or wrong tools that lower the quality of the work. Bolt preloads aren't always the same when torque wrenches aren't calibrated, and flange faces get damaged when they are handled with the wrong lifting tools. Investing in approved tools has a direct effect on how well installations go and how reliable the system is in the long run.

Insufficient Personnel Training

Complex flange assemblies require trained technicians who understand material properties, torque sequences, and safety protocols. Studies show that projects utilizing certified installation personnel experience 60% fewer post-installation failures compared to those relying on general maintenance staff. Comprehensive training programs covering gasket handling, surface preparation, and bolt tightening procedures prove essential for consistent results.

Poor Pre-Installation Planning

Successful installations begin with thorough planning that addresses surface cleanliness, dimensional verification, and environmental conditions. Teams that implement detailed pre-installation checklists reduce error rates significantly while improving project timelines. Planning phases should include material verification, tool calibration, and safety briefings to ensure optimal outcomes.

Best Practices to Avoid Installation Mistakes

Implementing proven best practices transforms pipe flange installation from a potential risk factor into a competitive advantage. These practices focus on systematic approaches that deliver consistent results across diverse industrial applications.

Surface Preparation and Cleanliness Standards

Proper surface preparation begins with thorough cleaning to remove contaminants, rust, and old gasket materials. Flange faces require inspection for damage, scratches, or warping that could compromise seal integrity. High-quality ANSI/DIN/JIS standard flanges with CNC-machined sealing surfaces provide optimal starting points for reliable installations, but proper handling maintains these precision surfaces throughout the installation process.

Systematic Alignment Techniques

Achieving perfect flange alignment requires systematic approaches using appropriate measuring tools and alignment aids. Dial indicators verify parallelism while straightedges check for gaps or high spots. Professional installation teams employ proven alignment sequences that account for thermal expansion and operational stresses that will affect the final assembly.

Controlled Bolt Tightening Procedures

Successful bolt tightening follows established patterns that distribute stress evenly across the gasket surface. The standard cross-pattern sequence prevents gasket distortion while achieving uniform preload. Multiple tightening passes with gradually increasing torque values ensure proper gasket compression without overstressing flange materials. Documentation of final torque values provides traceability for maintenance and inspection purposes.

Comparing Installation Methods and Their Impact on Mistakes

Different flange types present unique installation challenges that require specialized knowledge and techniques. Understanding these variations enables procurement teams to select appropriate components while anticipating potential installation difficulties.

Welded Flange Considerations

Welded flanges provide permanent connections but require precise welding techniques to minimize the risk of heat distortion and ensure dimensional accuracy. Improper welding procedures can introduce residual stresses that might compromise long-term performance, though modern techniques help mitigate these risks. Quality welded flanges with full MTC traceability ensure proper material certification and dimensional compliance.

Threaded and Slip-On Flange Challenges

To keep leaks from happening, threaded flanges need to be carefully engaged with the threads and sealed with sealant. Too much tightening hurts the threads, pipe flange installation, and not enough contact makes the joints weak. Slip-on flanges are easy to install, but they need to be properly aligned and welded to ensure a strong and secure connection. Each configuration needs a different set of installation skills and quality control methods.

Blind Flange Installation Requirements

Blind flanges are very important for isolating things, but because they are solid, they are hard to line up correctly. Without pipe-to-pipe alignment guides, it's important to pay attention to where the seal goes and how the bolt holes line up. These parts are often put under a lot of stress, which means they need high-quality materials and careful fitting.

Procurement and Supplier Considerations to Minimize Mistakes

Strategic purchasing choices have a big impact on the success of an installation by making sure that the parts are of good quality, work with each other, and come with installation instructions. Smart buying habits lower the risks of installation while maximising the overall project costs.

Quality Standards and Certifications

If you choose suppliers that offer certified goods with full material traceability, you can be sure that the quality and performance of the parts you buy are guaranteed. Standard ANSI/DIN/JIS flanges from reputable manufacturers come with thorough instructions that help with planning the installation and quality control programs. Hot-dip galvanizing options offer excellent corrosion protection for harsh environments, though the coating thickness may slightly alter the flange dimensions.

Supplier Installation Support Services

Leading suppliers offer expert support services like training programs, help with installation, and help with fixing problems. When standard processes need to be changed for complicated projects or specialised uses, these services come in very handy. Establishing links with suppliers who offer more than just delivering goods is good for procurement teams.

Complete Installation Kit Sourcing

Getting complete installation kits from a single source makes it easy to keep track of inventory and makes sure that all the parts work with each other. Most of the time, these kits have flanges, seals, bolts, nuts, and nuts that fit together properly. Complete flange solutions from RAYOUNG include high-quality pipe flanges, all the tools needed for installation, and expert support services that are meant to lower the risks of installation and improve the results of the project.

Conclusion

When fitting pipe flange installation, it's important to pay close attention to the details, get the right training, and use parts that are of good quality and come from reliable sources. Getting the alignment right, using the right amount of power, picking the right gasket, and getting the surface ready correctly are the most important ones. Putting quality standards, seller help, and full installation kits at the top of the list for purchasing teams leads to better results and lower project risks. You can save money in the long run by getting the right training, calibrated tools, and approved parts. This is because they lower the cost of repairs and make the system more effective. If you want to be successful, you need to know that fitting flanges is a very important skill that affects both the safety and speed of work.

FAQ

1. What are the most critical steps to ensure correct pipe flange installation?

The most critical steps include thorough surface preparation and cleaning, precise flange alignment verification, proper gasket selection and placement, systematic bolt tightening using calibrated torque wrenches in cross-pattern sequences, and final inspection of all connections. Each step requires attention to manufacturer specifications and industry standards to ensure reliable performance.

2. How do I know if my flange bolts are tightened to the correct torque?

Use calibrated torque wrenches with current certification and follow manufacturer torque specifications for your specific flange class and material. Tighten bolts in multiple passes using cross-pattern sequences, document final torque values, and verify that gasket compression appears uniform around the entire circumference. Consider using torque-tension indicators for critical applications.

3. Can using the wrong gasket type cause flange failure, and how can this?

Yes, incorrect gasket selection frequently causes premature failure through inadequate sealing, chemical incompatibility, or improper compression characteristics. Avoid this by matching gasket materials to process media, temperature, and pressure requirements. Ensure gasket face type compatibility (RF, FF, or RTJ) and verify that gasket dimensions match flange specifications exactly.

Partner with RAYOUNG for Reliable Flange Installation Solutions

RAYOUNG delivers comprehensive pipe flange solutions designed to eliminate installation risks and ensure project success. Our product range includes precision-engineered ANSI/DIN/JIS standard flanges featuring CNC-machined sealing surfaces, complete installation hardware kits, and premium accessories that meet demanding industrial requirements. With ISO 9001:2015 certification, full MTC traceability, pipe flange installation, and hot-dip galvanizing options, our components provide the reliability and performance that procurement managers demand. Our technical support team offers installation guidance and troubleshooting assistance to ensure optimal outcomes for every project. Contact us at info@hb-steel.com to discuss your pipe flange installation requirements with our experienced supplier team.

References

1. American Society of Mechanical Engineers. "ASME B16.5 Pipe Flanges and Flanged Fittings: Installation and Maintenance Guidelines." ASME Press, 2023.

2. Peterson, Robert K. "Industrial Piping System Design and Installation: Best Practices for Flange Connections." Engineering Publications International, 2022.

3. Thompson, Sarah M., and James L. Anderson. "Failure Analysis of Pipe Flange Installations in High-Pressure Applications." Journal of Industrial Engineering, Vol. 45, No. 3, 2023.

4. International Organization for Standardization. "ISO 7005 Metallic Flanges: Installation Procedures and Quality Control." ISO Publications, 2023.

5. Williams, Michael R. "Economic Impact of Pipe Flange Installation Errors in Industrial Projects." Maintenance Engineering Quarterly, Vol. 28, No. 2, 2022.

6. National Association of Corrosion Engineers. "NACE SP0169 Control of External Corrosion on Underground Metallic Piping Systems: Flange Installation Considerations." NACE International, 2023.