What’s the difference between blind flange and end cap?

Understanding the refinement between blind flanges and conclusion caps is basic for engineers and acquirement masters included in channeling framework plan. Whereas both components serve the principal reason of closing pipeline closes and avoiding liquid elude, they contrast essentially in development, establishment strategies, weight capabilities, and application appropriateness. Daze ribs connect to companion spines utilizing shot associations with gaskets, giving detachable closures perfect for frameworks requiring occasional get to for assessment, cleaning, or future extension. Conclusion caps, then again, ordinarily weld specifically onto pipe closes, making changeless closures suited for terminal focuses with negligible get to prerequisites. The choice between these closure strategies impacts establishment costs, support adaptability, weight evaluations, and long-term operational contemplations. This comprehensive examination looks at the basic contrasts, utilitarian characteristics, and application rules that educate ideal choice between daze spines and conclusion caps over differing mechanical environments.

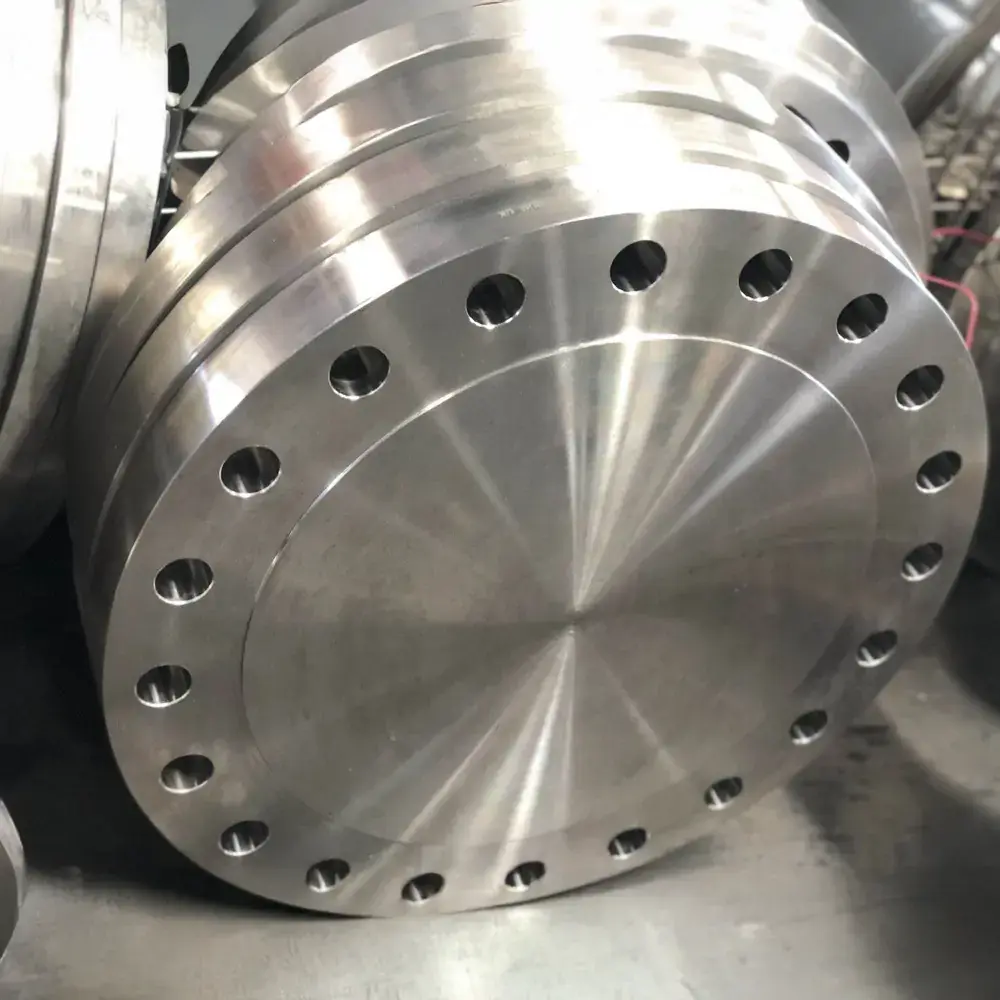

Structural and Design Differences Between Blind Flanges and End Caps

Construction and Configuration Characteristics

Blind ribs highlight strong disk development with jolt gaps organized in standardized designs around the outskirts, outlined to mate with companion spines on channels, valves, or gear spouts. The jolt circle breadth, gap amount, and dividing take after exact dimensional guidelines counting ASME B16.5 or EN 1092 determinations guaranteeing widespread compatibility. Raised confront setups on dazzle ribs give fixing surfaces that compress gaskets when jolts are fixed, making leak-tight obstructions against inside weight. The thickness shifts with weight lesson appraisals, with higher-pressure applications requiring significantly thicker disks to stand up to twisting minutes. Conclusion caps show on a very basic level diverse geometry, highlighting domed or circular head setups that move from the pipe distance across to a closed conclusion. Fabricating forms incorporate hot shaping, cold shaping, or machining from strong bar stock depending on estimate and fabric necessities. Butt-weld conclusion caps join beveled edges coordinating standard pipe divider arrangements, encouraging field welding amid installation.

Material Specifications and Manufacturing Standards

Both blind flanges and end caps are available in diverse material grades accommodating specific service requirements. Blind flanges typically comply with forging standards including ASTM A105 for carbon steel and A182 for stainless steels. The forging process imparts superior mechanical properties, making forged blind flanges preferred for critical high-pressure services. End caps follow separate standards like ASME B16.9 for wrought steel butt-welding fittings, while pressure vessel heads follow ASME Section VIII requirements. Material selection for both components must consider corrosion resistance, temperature capabilities, and mechanical strength requirements. Carbon steel serves general-purpose applications, while stainless steel grades address corrosive environments.

Pressure and Temperature Rating Capabilities

The pressure-containing capabilities of blind flanges and end caps differ fundamentally due to their distinct structural configurations. Blind flanges experience bending stresses as internal pressure acts uniformly across the solid disk, creating maximum stress at the bolt circle. ASME pressure class ratings for blind flanges account for these bending effects, with Class 150 through Class 2500 ratings accommodating progressively higher pressures. End caps distribute pressure loads differently, with curved geometries converting internal pressure into membrane stresses. This stress distribution proves more efficient, allowing end caps to achieve equivalent pressure ratings with less material thickness. However, welded attachment introduces stress concentrations requiring careful weld procedure qualification. Temperature ratings for both depend primarily on base material properties, with pressure derating required at elevated temperatures.

Installation Methods and Maintenance Requirements

Installation Procedures and Time Considerations

Installing dazzle spines includes mechanical blasting methods that permit generally fast get together without specialized welding gear or hot work grants. The prepare incorporates surface arrangement, gasket choice, situating the daze rib, and executing efficient fixing arrangements. This mechanical association regularly requires 30 to 60 minutes for standard establishments, allowing work in working plants with negligible disturbance. Conclusion cap establishment requests qualified welding methods, starting with legitimate fit-up between the beveled cap edge and arranged pipe conclusion. Total conclusion cap establishment counting welding, assessment, and potential post-weld warm treatment ordinarily requires a few hours to full days depending on measure and code requirements.

Removal and Replacement Procedures

The removable nature of blind flanges represents a key advantage for systems requiring periodic inspection or cleaning. Removal involves systematic bolt loosening and lifting the blind flange from the companion flange face, typically completing within an hour. Reinstallation follows the original procedure with new gasket material, making blind flanges ideal for applications anticipating regular maintenance cycles. End caps present substantial challenges for removal, requiring cutting operations that destroy the cap. Following internal work completion, new end caps must be welded in place, repeating the full installation procedure. This destructive removal process makes end caps economically unsuitable for applications requiring frequent access.

Long-Term Maintenance and Inspection Requirements

Blind flanges demand ongoing maintenance to ensure continued leak-tight performance. Periodic inspections verify bolt tightness, while leak detection surveys catch incipient gasket failures. Thermal cycling services may require periodic gasket replacement even without observed leakage. The gasketed joint configuration creates potential leak paths requiring vigilance in toxic or flammable services. End caps require less routine maintenance due to their welded construction, though weld integrity inspections remain important. Visual inspection identifies external corrosion, while ultrasonic thickness measurement and radiography assess weld quality. The permanent nature of welded end caps eliminates gasket-related maintenance concerns.

Application Selection Guidelines and Cost Considerations

Optimal Applications for Blind Flanges

Blind flanges excel in applications requiring removable access while maintaining full system pressure capability. Piping systems under construction often incorporate blind flanges at incomplete branches, allowing system pressurization while preserving future expansion options. Process equipment isolation during maintenance represents another ideal application, where removal provides access while adjacent systems remain operational. The mechanical connection method allows installation without hot work permits, valuable in operating facilities. Systems requiring periodic inspection or cleaning benefit from blind flange accessibility. High-pressure services demanding maximum pressure ratings favor blind flanges, as standardized ASME pressure classes extend through Class 2500.

Preferred End Cap Applications

End caps serve optimally in permanent closure applications where removal access is unlikely. Dead-end pipeline terminations typically employ end caps, as these locations rarely require opening. The streamlined profile of domed end caps reduces turbulence compared to flat blind flanges. Buried or inaccessible piping locations favor end caps, as welded construction eliminates potential leak points associated with gasketed joints. Applications involving frequent temperature cycling may prefer end caps, avoiding thermal expansion challenges. Space-constrained installations benefit from the compact profile of end caps, which eliminate the bolt circle projection required for blind flanges.

Economic Comparison and Life-Cycle Cost Analysis

Initial fabric costs favor conclusion caps for lasting establishments, with straightforward butt-weld caps costing significantly less than identical dazzle spines with gaskets and jolts. In any case, establishment costs present complexity, as welding strategies and assessment necessities considerably increment conclusion cap establishment costs. The life-cycle taken a toll condition must join upkeep and potential expulsion costs, where dazzle spines illustrate clear preferences in applications requiring intermittent get to. A single evacuation and reinstallation cycle regularly recoups the introductory fetched premium of daze ribs. Applications expecting intermittent future get to ought to indicate daze ribs from financial viewpoints. Alternately, affirmed lasting closures maximize conclusion cap financial benefits.

Conclusion

Blind ribs and conclusion caps serve particular parts in channeling frameworks, with daze ribs giving detachable get to through catapulted associations whereas conclusion caps offer lasting welded closures. Determination depends on get to necessities, weight appraisals, and financial contemplations. At HEBEI RAYOUNG PIPELINE Innovation CO., LTD., we fabricate both daze ribs and conclusion caps in comprehensive measure and fabric ranges, conveying components supported by ISO 9001:2015 certification, GOST-R compliance, and SGS approval for reliable quality over all applications.

FAQ

1. Can I replace an end cap with a blind flange?

Converting from welded end caps to blind flanges requires adding a companion flange to the pipe end through welding. This modification proves practical when future access becomes necessary. The companion flange must match pipe size and desired pressure rating, with proper weld procedures ensuring code compliance. Once installed, blind flanges provide removable access for inspection or future expansion without additional cutting operations.

2. Which closure method provides better sealing reliability?

Welded end caps theoretically provide superior long-term sealing reliability by eliminating gasketed joint leak paths, making them preferred for critical applications where leakage consequences outweigh access flexibility. However, properly installed and maintained blind flanges with appropriate gaskets achieve excellent sealing performance across most industrial services. The choice depends on service severity and access requirements rather than absolute sealing capability differences.

3. Do blind flanges and end caps require different pressure ratings?

Both blind flanges and end caps must be specified for pressure ratings matching or exceeding system design pressure with appropriate safety factors. Blind flanges follow ASME pressure class designations from 150 through 2500, while end caps specify wall thickness schedules providing equivalent pressure capability. The curved geometry of end caps creates more efficient stress distribution than flat blind flanges, though both achieve necessary pressure containment when properly specified.

4. What are typical lead times for blind flanges versus end caps?

Standard size blind flanges in common materials typically ship from stock or within two weeks, as their universal application drives manufacturer inventory programs. End caps in standard sizes also maintain good availability, though specialized sizes or materials may require manufacturing lead times of four to eight weeks. Custom components in non-standard dimensions or exotic materials face extended lead times potentially reaching 12 weeks or more.

Quality Blind Flanges and End Caps from HEBEI RAYOUNG PIPELINE: Trusted Manufacturers for Global Projects

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we believe that excellent infrastructure starts with dependable materials, and our comprehensive range of blind flanges and end caps exemplifies this commitment. As one of the leading pipes and fittings manufacturers, we supply high-quality closure components in carbon steel, stainless steel, and alloy materials. Our product lineup includes blind flanges from Class 150 through Class 2500 and end caps in all standard sizes, ensuring secure connection points for projects ranging from residential properties to industrial plants. We understand the importance of consistent quality, innovation, and reliability, backed by ISO 9001:2015 certification, GOST-R compliance, and SGS validation. Whether you need removable blind flanges for maintenance access or permanent end caps for terminal closures, our experienced team provides expert guidance. Contact us today at info@hb-steel.com to discuss your requirements and discover how RAYOUNG serves domestic and global markets as your dependable piping component supplier.

References

1. American Society of Mechanical Engineers. (2020). ASME B16.5: Pipe Flanges and Flanged Fittings NPS 1/2 through NPS 24. New York: ASME Press.

2. American Society of Mechanical Engineers. (2018). ASME B16.9: Factory-Made Wrought Buttwelding Fittings. New York: ASME Press.

3. Nayyar, M. L. (2021). Piping Handbook, Eighth Edition. New York: McGraw-Hill Education.

4. Becht, C. (2019). Process Piping Design Handbook Volume One: The Fundamentals of Piping Design. Houston: Becht Engineering Company.

5. European Committee for Standardization. (2018). EN 1092-1: Flanges and Their Joints - Circular Flanges for Pipes, Valves, Fittings and Accessories. Brussels: CEN Publications.

6. British Standards Institution. (2017). BS 10: Specification for Flanges and Bolting for Pipes, Valves and Fittings. London: BSI Standards Limited.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise