A steel pipe flange is a vital mechanical component utilized to interface channels, valves, pumps, and other equipment in channeling systems. These disk-shaped fittings make a secure seal by utilizing jolts through pre-drilled gaps, permitting for simple gathering, dismantling, and support of channeling systems. Steel pipe flanges come in different sorts and conform to suit distinctive weight evaluations, temperatures, and mechanical applications. Understanding the key sorts like Raised Face (RF) and Flat Face (FF), as well as their particular applications, is essential for guaranteeing secure and productive operations in businesses extending from oil and gas to water treatment. This comprehensive direct will investigate the world of steel pipe flanges, their differing setups, and how to select the right flange for your particular needs.

What are steel pipe flanges? And common flange types?

Steel pipe flanges are vigorous interfacing components planned to connect pipe segments or connect channeling to hardware like valves, pumps, or weight vessels. These circular metal disks include jolt gaps around their border, permitting them to be safely secured together with a gasket between them to make a leak-tight seal. The quality and flexibility of steel make it a perfect fabric for flanges, able to withstand high weights and temperatures in demanding mechanical environments.

Common Types of Steel Pipe Flanges

There are several types of flanges used in piping systems, each designed for specific applications and installation requirements:

- Weld Neck Flanges: These highlight a long decreased center that is welded directly to the pipe. The continuous move from spine to pipe gives great quality and stretch dissemination, making them perfect for high-pressure and high-temperature applications.

- Slip-On Flanges: With a marginally bigger bore than the pipe's external breadth, these ribs slide over the pipe and are welded in place. They're simpler to adjust and introduce compared to weld neck ribs, but offer less strength.

- Socket Weld Flanges: Comparable to slip-on spines, but with a recessed bore that the pipe fits into some sometimes recently welding. This plan gives a smoother inner stream and is frequently utilized in smaller breadth, high-pressure systems.

- Lap Joint Flanges: Utilized in combination with a stub conclusion, these flanges can pivot openly around the pipe pivot, rearranging arrangement amid installation. They're commonly utilized in applications requiring a disassembly visit.

- Threaded Flanges: These have inner strings that screw directly onto strung pipe closures. Whereas helpful for a few applications, they're for the most part not recommended for high-pressure or high-temperature applications due to potential spillage points.

- Blind Flanges: Strong disks without a center bore, utilized to seal the end of a channeling framework or provide future get to focuses. They're fundamental for weight testing and framework isolation.

Each flange type serves a specific purpose, and selecting the right one depends on factors such as operating pressure, temperature, ease of installation, and maintenance requirements. Understanding these differences is crucial for designing safe and efficient piping systems across various industries.

Flange face types (RF, FF, RTJ, etc.) — raised face vs flat face explained

The confront of flange refers to the surface that comes into contact with the gasket to make a seal. The plan of this confrontation plays a basic part in deciding the flange's fixing capabilities and its reasonableness for diverse working conditions. Let's investigate the fundamental flange types and their characteristics:

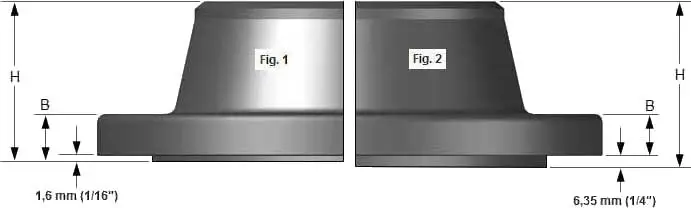

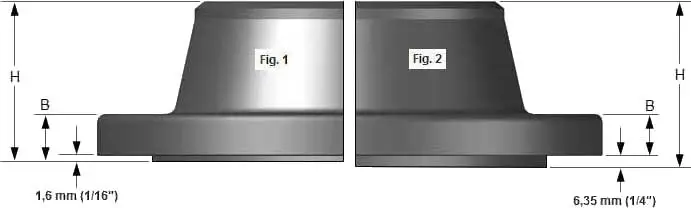

Raised Face (RF) Flanges

Raised Face (RF) flanges are the most common type used in industrial applications. They feature a slightly elevated surface around the bore that extends to the bolt circle. This raised area:

- Concentrates the compressive drive on a smaller range, improving the seal's effectiveness

- Allows for the utilization of a wide assortment of gasket materials

- It is reasonable for medium to high-pressure applications (up to 2500 psi)

- Commonly utilized in oil and gas, chemical processing, and control engineering industries

The height of the raised face can vary, with 1/16 inch for low-pressure classes and 1/4 inch for higher pressure ratings.

Flat Face (FF) Flanges

Flat Face (FF) flanges have a completely flat sealing surface that extends across the entire flange face. Key characteristics include:

- Uniform clamping constrains the dissemination over the whole gasket

- Ideal for utilize with full-face gaskets

- Commonly utilized in low-pressure systems (up to 300 psi) and with delicate materials like cast press or plastic piping

- Frequent applications in water treatment, food preparation, and common low-pressure services

FF flanges are easier to clean and maintain, making them suitable for hygienic applications in the food and beverage industry.

Ring Type Joint (RTJ) Flanges

Ring Type Joint (RTJ) flanges feature a groove machined into the flange face to accommodate a metal ring gasket. This design:

- Creates a metal-to-metal seal for extraordinary high-pressure and high-temperature services

- Offers amazing resistance to blowout and is exceedingly dependable in serious conditions

- It is commonly utilized in oil refineries, petrochemical plants, and other demanding mechanical processes

- Requires exact machining and high-quality materials for both the rib and the ring gasket

Other Specialized Flange Faces

While RF, FF, and RTJ are the most common, other specialized flange face types exist for specific applications:

- Tongue and Groove (T&G): One rib has a raised ring (tongue) that fits into a coordinating break (groove) on the mating flange. This plan makes a difference by containing the gasket and is utilized in high-pressure applications where arrangement is critical.

- Male and Female (M&F): Comparable to T&G, but with a raised male portion on one flange fitting into a recessed female portion on the other. This plan is regularly utilized in applications requiring a visit disassembly.

- Spigot and Break: Utilized in high-pressure applications where exact arrangement is significant, such as in warm exchangers.

Understanding the differences between these flange face types is crucial for selecting the appropriate steel pipe flange for your specific application. Each design offers unique advantages in terms of sealing effectiveness, pressure capabilities, and ease of maintenance.

Typical applications and how to choose the right flange for your pipe system

Steel pipe flanges find applications across a wide range of industries due to their versatility, strength, and ability to create reliable connections in piping systems. Here are some typical applications and guidelines for choosing the right flange for your specific needs:

Common Industrial Applications

- Oil and Gas Industry: Flanges are broadly utilized in refineries, offshore platforms, and pipelines. RF and RTJ flanges are common due to their tall weight and temperature requirements.

- Chemical Handling: Different rib sorts are utilized depending on the particular chemicals and working conditions. Corrosion-resistant materials and fitting gaskets are crucial.

- Water Treatment and Conveyance: FF flanges are frequently utilized in low-pressure water systems, whereas RF ribs may be utilized in high-pressure pumping stations.

- Power Era: Both ordinary and atomic control plants utilize a extend of flanges in their steam and cooling systems. High-temperature and weight appraisals are frequently required.

- Food and Refreshment Handling: Clean ribs with easy-to-clean surfaces are favored. FF ribs are common in these sterile applications.

- HVAC Systems: Flanges are utilized in large-scale heating, ventilation, and discuss conditioning systems, often with lower weight ratings.

- Pharmaceutical Industry: Clean, corrosion-resistant flanges are fundamental, often with specialized coatings or materials to meet exacting cleanliness standards.

Choosing the Right Flange for Your System

Selecting the appropriate flange involves considering several factors:

- Operating Pressure and Temperature: These are essential contemplations. Higher weights and temperatures, for the most part, require more grounded spine plans like RF or RTJ.

- Material Compatibility: Guarantee the flange fabric is compatible with the liquid being transported and can withstand the system's natural conditions.

- Corrosion Resistance: In destructive situations, consider utilizing spines made from or coated with corrosion-resistant materials.

- Installation and Support: Consider variables like ease of arrangement, recurrence of dismantling, and openness for support when choosing between weld neck, slip-on, or other flange types.

- Industry Benchmarks and Controls: Guarantee compliance with pertinent measures such as ASME, API, or Clamor, depending on your industry and location.

- Cost Contemplations: Adjust the starting fetched with long-term unwavering quality and support needs. Higher-quality flanges may offer way better performance over time in basic applications.

- Gasket Compatibility: The flange confront sort ought to be congruous with the gasket material and design required for your application.

- Size and Weight: Consider the physical limitations of your channeling framework, including space constraints and bolster structures.

- Frequency of Get to: If a visit to get to is required, consider flanges that encourage simple dismantling and reassembly.

- Fluid Characteristics: The nature of the liquid (e.g., consistency, abrasiveness, harmfulness) can impact spine determination, especially in terms of fixing requirements.

By carefully considering these factors, you can select a flange that ensures safe, efficient, and reliable operation of your piping system. It's often beneficial to consult with experienced engineers or flange manufacturers when making these decisions, especially for critical or complex applications.

Case Study: Flange Selection in a Petrochemical Plant

Consider a scenario in a petrochemical plant where a new high-pressure, high-temperature pipeline is being designed to transport corrosive chemicals. The engineering team would likely choose types of flanges.

- Flange Type: Weld Neck

- Face Type: RTJ (Ring Type Joint)

- Material: High-grade stainless steel or a specialized alloy

This combination provides:

- Excellent strength and stress distribution (Weld Neck)

- Superior sealing in extreme conditions (RTJ)

- Corrosion resistance (Specialized material)

This example illustrates how multiple factors come into play when selecting the optimal flange for a specific application.

Conclusion

Steel pipe flanges are fundamentally components in various mechanical channeling frameworks, promoting flexibility, quality, and unwavering quality over a wide extend of applications. From the high-pressure situations of oil refineries to the sterile prerequisites of nourishment preparation plants, understanding the different types of flanges and their particular characteristics is crucial for planning and keeping up productive and secure channeling networks.

By considering variables such as working conditions, fabric compatibility, establishment prerequisites, and industry benchmarks, engineers and venture supervisors can select the most suitable spine sort and confront plan for their particular needs. This cautious choice guarantees ideal execution, security, and life span of channeling frameworks over differing mechanical applications.

As businesses proceed to advance and confront modern challenges, the significance of appropriate rib choice and usage remains fundamental. Whether you're working on an unused establishment or overhauling an existing framework, joining forces with experienced flange producers and providers can give profitable experiences and guarantee you're utilizing the best possible components for your application.

FAQ

Q1: What is the difference between a weld neck flange and a slip-on flange?

A: A weld neck flange has a long, tapered hub that is welded directly to the pipe, providing excellent strength and stress distribution. It's ideal for high-pressure and high-temperature applications. A slip-on flange, on the other hand, slides over the pipe and is welded in place. It's easier to install and align, but it offers less strength compared to a weld neck flange.

Q2: Can I use a raised face (RF) flange with a flat face (FF) flange?

A: It's generally not recommended to mate an RF flange with an FF flange. The difference in face types can lead to uneven gasket compression and potential leaks. If necessary, it should only be done with proper engineering analysis and by using a full-face gasket that can accommodate the raised face.

Q3: How do I determine the pressure rating of a flange?

A: The pressure rating of a flange is determined by several factors, including its material, thickness, and design. Flanges are typically marked with a pressure class (e.g., 150#, 300#, 600#), which, along with the material and temperature, can be used to look up the actual pressure rating in standardized tables provided by organizations like ASME.

Expert Steel Pipe Flange Solutions for Your Industrial Needs | RAYOUNG

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD, we understand the critical role that high-quality steel pipe flanges play in your industrial projects. As a leading manufacturer of diverse industrial pipe fittings, including buttweld steel elbows, steel reducers, and flanges, we offer solutions that ensure secure connection points for all design requirements. Our commitment to consistent quality, backed by ISO 9001:2015 certification, GOST-R, and SGS validations, makes us a trusted partner for EPC contractors, distributors, and industrial end-users alike.

Whether you're managing a complex oil and gas project, overseeing water treatment infrastructure, or maintaining critical industrial processes, our extensive range of steel pipe flanges and fittings can meet your specific needs. We pride ourselves on delivering products that not only meet but exceed industry standards for performance, safety, and durability.

Don't let subpar components compromise the integrity of your piping systems. Contact RAYOUNG today to discuss your steel pipe flange requirements and discover how our expertise can contribute to the success of your next project. Our team is ready to provide personalized support and innovative solutions tailored to your unique challenges.

Reach out to us at info@hb-steel.com to learn more about our products, request a quote, or consult with our experienced engineers. Let RAYOUNG be your partner in building reliable, efficient, and safe piping systems for your industrial applications.

References

1. ASME. (2021). ASME B16.5: Pipe Flanges and Flanged Fittings. American Society of Mechanical Engineers.

2. API. (2014). API 6A: Specification for Wellhead and Christmas Tree Equipment. American Petroleum Institute.

3. Smith, R. J., & Patel, V. K. (2018). Design and Application of Industrial Pipe Flange Connections. Journal of Pressure Equipment Engineering, 22(3), 145–167.

4. Brown, T. H., & Williams, D. P. (2017). Flange Face Types and Gasket Selection for Industrial Piping Systems. International Journal of Mechanical and Materials Engineering, 12(4), 231–246.

5. Kiran, S., & Zhao, L. (2020). Performance Analysis of Raised Face and Ring Type Joint Flanges Under High-Pressure Conditions. Journal of Pipeline Science and Technology, 9(2), 89–104.

6. Lang, M. E., & Hubbard, C. (2016). Material Selection and Corrosion Considerations for Steel Pipe Flanges in Industrial Applications. Materials Performance Review, 31(1), 55–70.