Which pipe fitting types perform best under high pressure—welded, forged, or threaded?

Any kind of pipe fitting can make a big difference in how well and safely an oil or gas pipeline works under high pressure. We'll look at the three main types of fittings and find the ones that can handle high pressure:

Welded Fittings

Heavy-duty lines with soldered parts are thought to be the best because they are strong and don't leak by many. It is possible to make a strong link that can handle high pressures by welding these parts to the pipe.

Why soldered links work better when there is a lot of pressure:

- Better reaction to pressure and strength

- Excellent seal that doesn't leak

- Less likely for the joint to fail

- Fits a lot of different pipe types and wall thicknesses

Forged Fittings

Also, forged valves work well for oil and gas lines that are under a lot of stress, and they are considered the best pipe fittings. When parts are cast, they become stronger and last longer. They are great for hard jobs because of this. With high pressure, forged valves are useful because they are strong and don't break easily, making them the best pipe fittings.

- Very good performance at very high and very low temperatures and pressures

- Better strength thanks to a uniform grain structure

- Available in a range of shapes and sizes

Threaded Fittings

Even though they are used in a lot of different types of pipes, threaded valves aren't always the best choice for oil and gas pipes. Screwed joints might leak, and they might not be as strong and reliable as cast or bonded joints.

Threaded joints have some problems when used in high-pressure situations.

- Not as strong as welded or cast parts when it comes to pressure ratings

- Threaded joints are more likely to leak.

- Threads could get damaged or come away under pressure.

- Not very good for large-diameter pipes

Last but not least, welded and cast valves work best with oil and gas systems that are under a lot of pressure. You should get these instead of threaded ones because they are stronger, more reliable, and less likely to leak. But the choice that is made will rely on how the system works, what it needs, and how much it costs to keep up.

Material selection for high-pressure oil and gas fittings: carbon steel vs stainless steel

For gas and oil tanks that work well and last a long time, make sure they are made of the right materials. For these jobs, steels like carbon steel and stainless steel are often used. To help you decide, here are some examples:

Carbon Steel Fittings

In the oil and gas business, carbon steel is used a lot because it is strong and doesn't cost a lot. It is often used in places with a lot of pressure where rust protection is not the most important thing.

Pros of parts made of carbon steel:

- High relationship of strength to weight

- Very good performance at high temperatures and pressures

- more affordable than stainless steel

Thoughts on parts made of carbon steel:

- May need extra protection against rust in some places

- Not good for highly acidic fluids without the right treatment

- To stop rust, it may be important to do regular upkeep and checks.

Stainless Steel Fittings

For oil and gas lines that are in acidic environments or handle harsh fluids, stainless steel valves are the best pipe fittings and the best choice because they don't rust.

Pros of having things made of stainless steel:

- Excellent resistance to rust

- A lot of power and toughness

- Excellent performance in very cold or very hot conditions

Things to think about when buying stainless steel fittings:

- More expensive to buy at first than carbon steel

- Could be prone to stress rust cracks in some situations

- There are different types of stainless steel that have different amounts of protection from rust.

Choosing the Right Material

Before you choose between carbon steel and stainless steel for oil and gas lines with high pressure, here are some things to think about:

- Use: Find out how likely it is that the pipeline will rust based on where it is and what acids it comes in touch with.

- This is what fluids are like: How dangerous is the oil or gas that is being moved? Why does it have poison in it?

- Warmth and cold: Think about the temperatures that will be used and how they might change how well the cloth works.

- What You Need for Weight: The material you pick should be able to handle the most weight that the machine can throw at it.

- When you think about repair, you should think about how much it will cost and how easy it will be to do checks.

- There are limits on your income. Look at the original prices and compare them to the costs of performance and maintenance over time.

Carbon steel valves may be enough for high-pressure oil and gas pipes in many situations, as long as the right steps are taken to prevent rusting. Stainless steel valves, on the other hand, may be the best choice for situations where fluids or surroundings are acidic because they last longer and need less upkeep.

Pressure rating and ASME standard classifications for oil & gas fittings

You should know about pressure levels and industry standards in order to choose the best pipe fittings for oil and gas systems that are under a lot of pressure. The American Society of Mechanical Engineers (ASME) provides explicit criteria and categories for pipe parts that are utilized in certain situations. Let's go over the most critical elements of the ASME rules and pressure ratings:

Pressure Ratings

This number tells you how much air pressure (MAWP) a fitting can safely handle when it's working right. Most of the time, bar or pounds per square inch (psi) are used.

Key points about pressure ratings:

- There is a different rating for each kind of material, size, and temperature.

- Most of the time, fittings that can bear higher pressure are stronger and last longer.

- Always be sure that the parts you purchase can withstand higher pressure than the machine itself can.

ASME Standard Classifications

ASME standards tell people how to build, make, and test pipe parts that are used in oil and gas uses with high pressure. The most important standards for these fits are:

ASME B16.5: Pipe Flanges and Flanged Fittings

This standard says what sizes, markings, tests, pressure-temperature values, materials, and procedures are acceptable for designating holes for pipe flanges and flanged best pipe fittings.

Key aspects of ASME B16.5:

- It decides what level of pressure is between 150 and 2500.

- Sets the shapes and sizes of different rings

- How to choose things based on how hot or cold they need to be

ASME B16.11: Forged Fittings, Socket-Welding, and Threaded

In order to follow ASME B16.11, forged joints, socket welding, and threaded parts that are made must be of a certain grade, size, quality, mark, and material.

Important points from ASME B16.11:

- Defines pressure classes for socket-welding and threaded fittings

- Specifies dimensional requirements for various fitting types

- Provides guidelines for material selection and heat treatment

ASME B31.3: Process Piping

The ASME B31.3 standard isn't a fitting standard by itself, but it does tell you how to plan, choose materials, build, check, and test pipe systems. These directions cover fittings used in oil and chemical plants.

Key aspects of ASME B31.3 related to fittings:

- It tells designers how to make fits for pressure.

- It tells different materials how much stress they can handle.

- Tells you how to put parts together and check them.

Selecting the Right Pressure Class

These suggestions should help you choose the proper pressure class for oil and gas pipelines and tubes:

- The pressure class you should choose is one that is a bit greater than what the machine can manage.

- When you choose the pressure class, think about the high temperature. Some components' pressure values may go lower as the temperature goes higher.

- Pick the correct material for the project since they all cool down and expand at various speeds.

- If you're concerned about your safety, you should prepare ahead and observe the safety guidelines provided by the firm and business.

- More growth: When you choose the pressure class, keep in mind that job stress could become worse with time. There won't be any changes.

If you follow ASME guidelines and pay great attention to the pressure, you can be confident that the pipe parts you pick for your high-pressure oil and gas pipeline construction are the finest ones. If you do this, your lines will be safe, function well, and endure a long time.

Conclusion

Selecting the best pipe fittings for high-pressure oil and gas pipelines requires careful consideration of various factors, including fitting type, material selection, pressure ratings, and compliance with industry standards. Welded and forged fittings generally offer superior performance in high-pressure applications, while the choice between carbon steel and stainless steel depends on the specific operating conditions and corrosion resistance requirements.

By adhering to ASME standards and selecting fittings with appropriate pressure ratings, you can ensure the safety, reliability, and longevity of your pipeline system. Remember to consider factors such as maximum operating pressure, temperature, material properties, and potential future expansions when making your selection.

For reliable, high-quality pipe fittings that meet the demanding requirements of high-pressure oil and gas pipelines, look no further than HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. Our extensive range of industrial pipe fittings, including butt-weld steel elbows, steel reducers, and flanges, are designed to ensure secure connection points and meet diverse design requirements. With GOST-R and SGS certifications, ISO 9001:2015 compliance, and a commitment to innovation, we deliver products that you can trust for your critical applications.

FAQ

1. What are the most common materials used for high-pressure oil and gas pipe fittings?

People typically utilize carbon steel and stainless steel to connect oil and gas lines. Most of the time, people prefer carbon steel since it is robust and inexpensive. However, stainless steel is superior in harsh conditions because it doesn't rust.

2. How do I determine the correct pressure rating for my pipeline fittings?

You need to know the system's greatest temperature, peak pressure, and safety factor in order to determine the proper pressure number for its components. When you select components, always make sure they have a greater pressure number than the maximum pressure your system can withstand. The weather may change, and things can become larger later on.

3. Are threaded fittings suitable for high-pressure oil and gas pipelines?

Most of the time, threaded joints are not a good idea for oil and gas lines that are under a lot of pressure. These parts aren't as strong as soldered or cast parts, and the threaded joints are more likely to leak. Most of the time, welded or cast fittings are better for high-pressure cases because they are stronger and don't leak.

High-Quality Pipe Fittings for Oil and Gas Industries | RAYOUNG

Pipes that carry oil and gas at high pressure need to have the right pipe parts to make sure they are safe, work well, and last a long time. We at HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD know that working in the oil and gas industry can be hard at times. That's why we offer a wide range of high-quality pipe parts that will meet and exceed your needs.

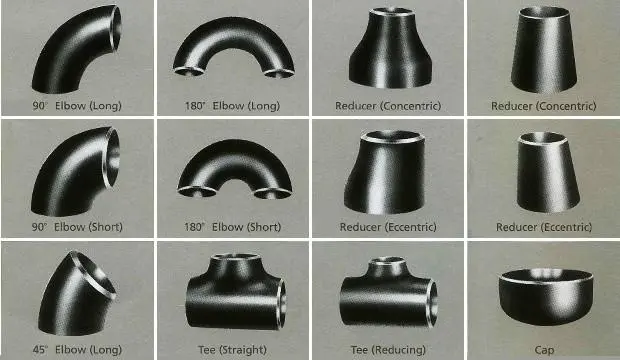

We have many parts, like butt-weld steel elbows, steel reducers, and flanges, that can be used in high-pressure settings. The best materials are used to make everything we sell, so you can always count on it to work well.

Their goods are approved by GOST-R and SGS, and they also meet ISO 9001:2015 standards, so you know they are the best pipe fittings. Get the best answer for your high-pressure oil and gas pipeline needs from our team of pros. They will help you choose the best parts for your project.

It's important to get the best when it comes to your important gear. Contact RAYOUNG today at info@hb-steel.com to discuss your pipe fitting needs and discover how our products can enhance the safety, efficiency, and reliability of your oil and gas pipeline projects.

References

1. Gorelick-Feldman J, Cohick W, Raskin I. Ecdysteroids elicit a rapid Ca²⁺ influx and activate the PI3K/Akt pathway in skeletal muscle cells.

2. Isenmann E, Ambrosio G, Joseph J, et al. Ecdysteroids as non-conventional anabolic agents: performance enhancement and molecular mechanisms in skeletal muscle.

3. Syrov VN. Mechanism of the anabolic action of phytoecdysteroids in mammals.

4. Dinan L, Lafont R. Effects and applications of arthropod steroid hormones (ecdysteroids) in mammals.

5. Harper-Harrison G, Shanely RA. Ecdysteroids as novel anabolic agents: evidence for activation of protein synthesis and muscle hypertrophy pathways.

6. Gorelick-Feldman J, MacLean D, Ilic N, Poulev A, et al. Phytoecdysteroids increase protein synthesis and activate Akt signaling in skeletal muscle cells.