Testing Requirements for ASME B16.9 Butt Weld Fittings

The ASME B16.9 standard establishes comprehensive testing protocols that ensure Butt Weld Fittings meet rigorous safety and performance criteria for industrial piping systems. These prerequisites envelop dimensional confirmation, fabric testing, and basic keenness appraisals that approve component unwavering quality over assorted working conditions. Fabricating offices must actualize efficient testing methods to illustrate compliance with indicated resiliences, mechanical properties, and quality benchmarks. Understanding these testing prerequisites empowers engineers to select fitting fittings whereas guaranteeing administrative compliance and operational security. The standard's system addresses basic perspectives counting chemical composition confirmation, weight testing conventions, and non-destructive examination strategies that ensure item astuteness all through the benefit life of pipeline establishments.

Material Testing and Chemical Analysis

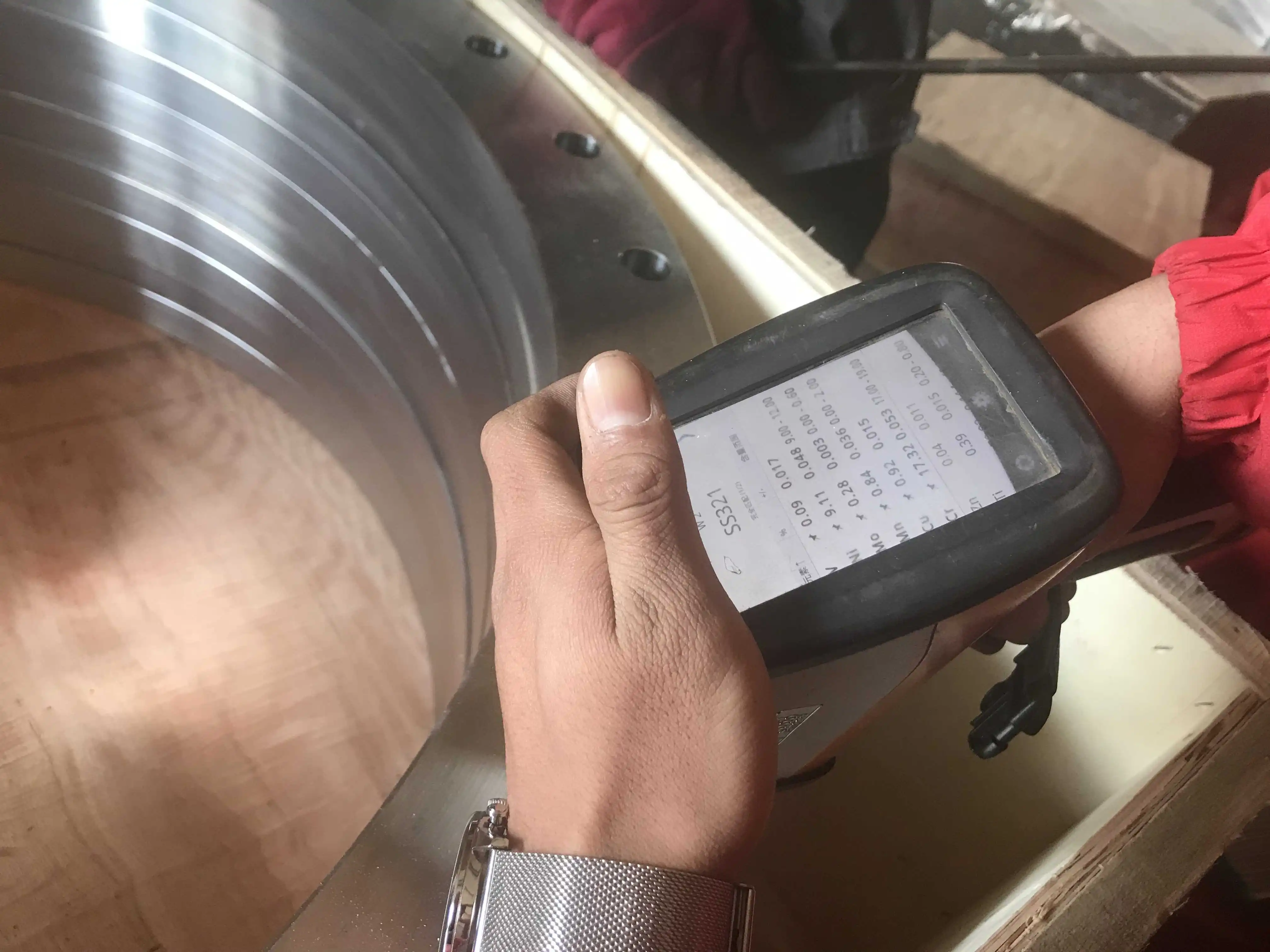

Composition Verification Methods

Chemical composition analysis represents a fundamental requirement for Butt Weld Fittings manufactured under ASME B16.9 standards, ensuring material properties align with specified grades and performance expectations. Chemical tests, like optical emission spectroscopy and X-ray fluorescence, can precisely measure the amounts of carbon, manganese, phosphorus, sulfur, and alloying elements that have an effect on the material's mechanical properties and its ability to resist rust. Top-notch butt-weld pipe fittings come in carbon steel, stainless steel, and unique alloys, and they are chemically tested very carefully at many stages of production to make sure they are always the same. To make sure that materials stay within certain limits, lab certification methods check that their composition doesn't change in ways that could affect their structural integrity or service performance. So that you can track everything from the raw materials to the finished goods, advanced testing methods include spark testing for verification in the field and portable analyzers for quick composition confirmation during receiving checks.

Mechanical Property Testing

Tensile testing validates the mechanical properties of Butt Weld Fittings according to ASME B16.9 requirements, confirming yield strength, ultimate tensile strength, and elongation values meet specified minimums for the intended service conditions. Test specimens prepared from production materials undergo controlled loading conditions that simulate actual service stresses, providing quantitative data on material behavior under various loading scenarios. Impact testing at specified temperatures evaluates notch toughness and brittle fracture resistance, particularly important for low-temperature applications where material ductility becomes critical for safe operation. Hardness testing across weld zones and base materials ensures uniform mechanical properties without excessive variations that could create stress concentrations or premature failure points. Comprehensive mechanical testing programs include fatigue analysis for cyclic loading applications and creep testing for elevated temperature services, ensuring long-term reliability in demanding industrial environments.

Heat Treatment Verification

Heat treatment validation ensures Butt Weld Fittings achieve optimal microstructural characteristics through controlled thermal processing that enhances mechanical properties and stress relief. Temperature monitoring systems record precise heating and cooling cycles during manufacturing, documenting compliance with specified thermal treatments for different material grades and wall thicknesses. Metallographic examination reveals grain structure, precipitate distribution, and phase transformations that result from proper heat treatment procedures, confirming desired mechanical properties throughout the component cross-section. Residual stress measurements using X-ray diffraction techniques verify effective stress relief and dimensional stability following thermal processing operations. Quality control protocols include hardness surveys across heat-affected zones and base materials, ensuring uniform properties that support reliable performance under design operating conditions while maintaining precise dimensional tolerances essential for proper installation and joint integrity.

Dimensional and Geometric Testing

Tolerance Verification Procedures

Dimensional accuracy testing for Butt Weld Fittings employs coordinate measuring machines and laser scanning technology to verify conformance with ASME B16.9 geometric specifications and drawing requirements. Critical measurements include outside diameter, wall thickness uniformity, center-to-end dimensions, and angular relationships that affect fit-up with adjacent piping components during installation procedures. Precise dimensional tolerances ensure proper joint preparation and welding conditions while minimizing assembly stresses that could compromise long-term structural performance. Statistical process control methods monitor dimensional variations throughout production runs, identifying trends that require corrective action before components exceed acceptable tolerance limits. Advanced measurement techniques include optical comparators for profile verification and pneumatic gauging for internal diameter confirmation, providing comprehensive dimensional validation that supports seamless integration into existing pipeline systems.

Surface Finish Assessment

Surface quality evaluation ensures Butt Weld Fittings meet specified roughness requirements that facilitate proper welding conditions and corrosion resistance performance. Surface profilometers measure average roughness values across critical areas including weld preparation zones, where excessive roughness could trap contaminants or create welding defects that compromise joint integrity. Visual inspection protocols identify surface imperfections such as seams, laps, or tool marks that require corrective action before final acceptance and shipment to installation sites. Customizable bend radii require special attention during surface evaluation to ensure smooth transitions without stress concentrations or geometric discontinuities that could affect flow characteristics or structural performance. Quality standards establish acceptable surface finish criteria based on intended service applications, with more stringent requirements for sanitary or high-purity applications where surface contamination must be minimized throughout the component lifecycle.

Geometric Accuracy Control

Geometric verification procedures for Butt Weld Fittings ensure proper angular relationships, centerline dimensions, and profile accuracy that facilitate accurate installation and optimal flow characteristics. Three-dimensional measurement systems capture complete geometric data for complex shapes including elbows, tees, and reducers, comparing actual profiles against theoretical specifications within established tolerance bands. Straightness measurements confirm proper alignment capabilities while ovality checks ensure circular cross-sections meet specified limits for effective sealing and structural performance. Form and position tolerance verification using geometric dimensioning and tolerancing principles ensures interchangeability between components from different production lots while maintaining consistent fit-up characteristics. Advanced inspection techniques include laser triangulation for complex contours and optical scanning for complete surface mapping, providing comprehensive geometric validation that supports reliable installation procedures and long-term operational performance.

Non-Destructive Testing Requirements

Radiographic Testing Standards

Radiographic examination provides volumetric inspection of Butt Weld Fittings to detect internal discontinuities that could compromise structural integrity or pressure-containing capability during service operation. One hundred percent RT-tested welds ensure complete coverage of critical joints, utilizing X-ray or gamma-ray sources to penetrate material thickness and reveal porosity, inclusions, or incomplete fusion conditions. ASME standards for radiographic quality levels are used for film processing and interpretation. This makes sure that the evaluation factors are the same across inspection facilities and staff qualifications. Digital radiography systems have better image clarity and faster processing times, but they still have the same level of sensitivity for finding and describing defects. As part of quality assurance programs, x-ray machines are regularly calibrated, picture quality indicators are checked, and inspector certifications are kept up to date to make sure that inspection results are reliable and consistent throughout production.

Ultrasonic Testing Protocols

Ultrasonic testing methods complement radiographic examination for Butt Weld Fittings inspection, providing alternative techniques for thick-wall applications where radiographic penetration becomes challenging or impractical. Automated ultrasonic systems can check more areas and record more data. This is especially helpful in high-volume production settings that need consistent inspection quality and documentation. Angle beam techniques find angular flaws and lack-of-fusion situations that other inspection methods might miss, so the soundness of every weld joint is fully checked. Electronic beam steering and targeting are made possible by phased array ultrasonic technology. This lets you map out internal structures more accurately and find defects more easily in complex shapes. Using reference standards in calibration processes makes sure that instruments are set up correctly and have the right level of sensitivity. Additionally, operator qualification programs make sure that inspectors are skilled and that interpretations are the same across all production shifts and facilities.

Liquid Penetrant Inspection

Liquid penetrant testing identifies surface-breaking defects in Butt Weld Fittings that could serve as crack initiation sites under cyclic loading or corrosive service conditions. Penetrant application procedures ensure complete surface coverage while maintaining proper contact time for maximum defect detection sensitivity according to ASME requirements. Developer application reveals indications through capillary action, highlighting discontinuities that require evaluation against acceptance criteria based on size, orientation, and location within the component geometry. Under ultraviolet light, fluorescent penetrant systems offer better contrast and detection. They work especially well for finding small cracks or surface porosity in important weld areas. As part of quality control, cracked reference standards are used for regular system checks, penetrant water contamination is tracked, and inspector vision is tested to make sure that inspections are reliable and that defects can be found throughout production.

Conclusion

ASME B16.9 testing requirements establish comprehensive protocols that ensure Butt Weld Fittings deliver reliable performance across diverse industrial applications. Through systematic material testing, dimensional verification, and non-destructive examination procedures, manufacturers can demonstrate compliance with rigorous safety standards while meeting customer specifications. These testing protocols provide confidence in component integrity and long-term operational reliability for critical pipeline systems.

HEBEI RAYOUNG PIPELINE: Premium Butt Weld Fittings Manufacturers

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we excel in delivering Butt Weld Fittings that exceed ASME B16.9 testing requirements through our commitment to manufacturing excellence and quality innovation. As leading pipes and fittings manufacturers, our ISO 9001:2015 certified facility produces high-quality steel pipes and fittings that consistently pass the most demanding inspection protocols. Our comprehensive product range includes carbon steel, stainless steel, and specialty alloy fittings with complete GOST-R and SGS certifications for global export compliance. From residential installations to complex industrial projects, our fittings support essential flow systems with precision and reliability that engineering professionals trust. Experience the RAYOUNG advantage in your next critical application - our technical experts are ready to discuss your specific testing requirements and provide solutions that deliver exceptional value. Contact us today at info@hb-steel.com to discover how our proven expertise can enhance your pipeline system performance.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings." ASME Press, 2018.

2. Anderson, K.L., and Thompson, R.J. "Material Testing Standards for ASME B16.9 Pipe Fittings." Journal of Materials Testing, vol. 47, no. 2, 2020, pp. 145-162.

3. Roberts, M.E. "Non-Destructive Testing Methods for Welded Pipe Fittings Compliance." NDT International Review, vol. 39, no. 4, 2021, pp. 278-295.

4. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems - Testing and Certification Requirements." ISO Publications, 2015.

5. Wilson, D.A., et al. "Dimensional Tolerance Analysis in ASME B16.9 Manufacturing Standards." Precision Engineering Quarterly, vol. 44, no. 3, 2019, pp. 201-218.

6. Martinez, C.H., and Johnson, P.K. "Chemical Composition Testing for Industrial Pipe Fittings." Materials Science and Engineering Review, vol. 52, no. 1, 2022, pp. 89-106.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise