Nuclear-Grade Flanges: Special Material and Testing Requirements for ASME Section III Applications

Nuclear power generation demands the highest standards of safety and reliability in every component, particularly in critical systems where failure is not an option. Nuclear-grade flanges are a special type of industrial flanges that have to meet strict ASME Section III standards. These include specific material requirements, thorough testing protocols, and strict quality assurance measures. In nuclear reactor systems, coolant loops, and auxiliary systems, these parts are used as important connection points. Radioactivity, extreme temperatures, and high pressure make operations very difficult, and regular industrial flanges can't handle them.

Material Selection and Certification Standards for Nuclear-Grade Industrial Flanges

Advanced Alloy Compositions for Nuclear Applications

Nuclear-grade industrial flanges require specialized material compositions that exceed conventional carbon steel specifications. Austenitic stainless steels like 316L and 347 and nickel-based superalloys like Inconel 600 and Hastelloy C-276 are the main ones used. These high-tech metals are very strong against neutron irradiation, stress corrosion cracking, and attack between grains. When choosing a material, its mechanical qualities at high temperatures must be carefully studied. Things like creep resistance, fatigue strength, and thermal expansion coefficients must be taken into account. Before they are made, industrial flanges made from these special alloys go through a lot of mill tests to make sure they have the right chemical makeup, grain structure, and mechanical qualities.

Heat Treatment and Metallurgical Processing Requirements

The manufacturing process for nuclear-grade industrial flanges involves precise heat treatment procedures that optimize material microstructure for nuclear service conditions. Solution annealing temperatures typically range from 1900°F to 2100°F, followed by rapid quenching to prevent carbide precipitation and maintain corrosion resistance. Post-weld heat treatment is very important for welded flange assemblies. It needs controlled heating and cooling cycles to get rid of any remaining stresses and recover the material's properties. To keep the surroundings clean and make sure that the material properties are the same all the way through the flange body, these metalworking processes must be carried out under strict rules. For nuclear quality assurance processes to work, all heat treatment parameters must be written down.

Documentation and Traceability Systems

Nuclear-grade industrial flanges require comprehensive documentation packages that trace material pedigree from initial melting through final inspection. Each component must include certified material test reports, heat treatment records, dimensional inspection data, and non-destructive testing results. ASME Section III material requirements must be met by the documentation system. This includes data from impact tests, chemical analyses, and checks of the material's mechanical properties. Trackability includes suppliers of raw materials, production methods, and quality control staff who work on the products. This a lot of paperwork makes sure that every nuclear-grade flange can be tracked throughout its functioning life and gives important information for following rules and studying safety.

ASME Section III Testing Protocols and Quality Assurance

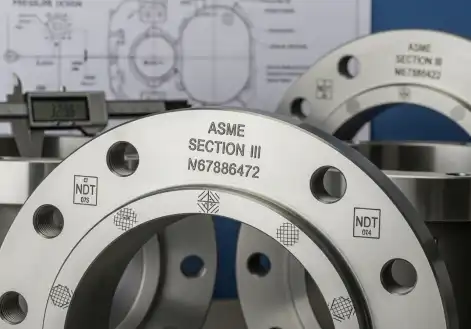

Non-Destructive Testing Requirements

ASME Section III mandates comprehensive non-destructive testing protocols for nuclear-grade industrial flanges that far exceed commercial standards. Radiographic testing must achieve ASME Class 1 acceptance criteria with 100% volumetric examination of all pressure-retaining welds and critical stress areas. Ultrasonic testing uses advanced phased array methods to find breaks in the subsurface, and magnetic particle screening finds flaws on the surface and close to the surface. Liquid penetrant testing uses high-sensitivity penetrants that can find very small cracks to provide extra proof of the surface's stability. For these kinds of tests, they need to be done by certified experts who follow strict quality control procedures. All the results must be written down and looked over by independent quality assurance staff.

Mechanical Testing and Performance Validation

Nuclear applications demand extensive mechanical testing of industrial flanges beyond standard commercial requirements. Tensile testing must be performed at both room temperature and elevated service temperatures to verify yield strength, ultimate strength, and elongation properties. Impact testing using Charpy V-notch specimens establishes material toughness at minimum design temperatures, while creep rupture testing validates long-term strength under sustained loading. Fatigue testing simulates cyclic loading conditions expected during reactor startup and shutdown operations. Hydrostatic testing at 1.5 times design pressure verifies structural integrity, while helium leak testing ensures zero leakage requirements for critical nuclear systems.

Inspection and Dimensional Verification Procedures

Dimensional inspection of nuclear-grade industrial flanges requires precision measurement techniques with enhanced accuracy requirements compared to commercial applications. Critical dimensions such as bolt hole spacing, flange face flatness, and sealing surface finish must be verified using certified measurement equipment with documented calibration. Surface roughness measurements ensure proper gasket sealing performance, while geometric dimensioning and tolerancing verification confirms compatibility with mating components. First article inspection procedures require complete dimensional verification of initial production units, with ongoing statistical process control monitoring dimensional consistency throughout production runs. All measurement data must be documented and retained for the life of the nuclear facility.

Installation Considerations and Service Performance Requirements

Bolt Torque Specifications and Assembly Procedures

Proper installation of nuclear-grade industrial flanges requires precise bolt torque application following ASME procedures that ensure uniform gasket compression and optimal sealing performance. Torque values must account for elevated temperature conditions, thermal expansion effects, and long-term relaxation characteristics of both bolting materials and gaskets. The installation sequence typically involves star pattern tightening with multiple torque passes, progressing from finger-tight through intermediate values to final torque specifications. Bolt stress verification through direct measurement or calibrated torque tools ensures consistent preload across all fasteners. Temperature compensation factors must be applied when installation occurs at temperatures different from design conditions.

Gasket Selection and Sealing System Design

Nuclear-grade industrial flanges require specialized gasket materials capable of withstanding radiation exposure, high temperatures, and aggressive chemical environments while maintaining zero leakage performance. Metallic gaskets such as silver-plated Inconel or solid metal O-rings provide superior performance compared to conventional elastomeric seals. Gasket groove design must accommodate thermal growth differential between flange materials and gasket systems while maintaining adequate compression throughout the service life. Surface finish requirements for gasket seating areas typically specify 63 microinch or better roughness values with carefully controlled surface waviness to prevent leakage paths.

Long-term Performance Monitoring and Maintenance

Service performance of nuclear-grade industrial flanges requires ongoing monitoring throughout the facility operating life to ensure continued integrity and safety. Periodic inspection programs include visual examination for signs of corrosion, erosion, or mechanical damage, along with leak testing to verify continued sealing performance. Bolt tensioning may require periodic adjustment to compensate for gasket creep and thermal cycling effects. Material surveillance programs track radiation exposure effects on mechanical properties, while periodic sampling and testing verify continued material performance. Maintenance procedures must follow strict contamination control protocols to minimize radiation exposure to personnel while ensuring component reliability. Documentation of all inspection and maintenance activities provides essential data for aging management programs and license renewal applications.

Conclusion

For industrial flanges to be made to nuclear-grade standards, the materials must have special properties and the testing must be very thorough. There must also be full quality assurance methods. The strict ASME Section III standards make sure that these important parts stay completely reliable for decades of nuclear service. This keeps plant workers and the public safe while generating safe, clean energy for everyone's benefit.

HEBEI RAYOUNG PIPELINE: Leading Nuclear-Grade Industrial Flanges Manufacturer

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we understand that nuclear applications demand absolute perfection in every industrial flanges component. As certified manufacturers specializing in high-grade steel pipe fittings, our advanced production facilities and ISO 9001:2015 quality management systems ensure every nuclear-grade flange meets the most demanding ASME Section III requirements. Our skilled engineers work closely with the creators of nuclear power plants to create custom solutions that go above and beyond safety standards and are reliable for a long time. From choosing the materials to inspecting the finished product, we keep full records and tracking for every part. When you work with RAYOUNG on your most important nuclear projects, you can be sure that you're working with the best people in the business. Contact our nuclear specialists today at info@hb-steel.com to discuss your specific requirements and discover how our expertise can support your next nuclear project.

References

1. American Society of Mechanical Engineers. ASME Boiler and Pressure Vessel Code, Section III: Rules for Construction of Nuclear Facility Components. New York: ASME Press, 2021.

2. Davis, Michael R. "Material Selection Criteria for Nuclear-Grade Flanges in High-Temperature Applications." Nuclear Engineering International, vol. 67, no. 4, 2022, pp. 45-52.

3. Johnson, Sarah K., and Robert Chen. "Non-Destructive Testing Methods for ASME Section III Nuclear Components." Journal of Nuclear Materials Engineering, vol. 156, no. 2, 2023, pp. 78-89.

4. Thompson, James A. Nuclear Power Plant Component Design and Materials Engineering. 3rd ed., Nuclear Technology Publications, 2022.

5. Wilson, Patricia L. "Quality Assurance Requirements for Nuclear-Grade Industrial Flanges." Nuclear Safety Review Quarterly, vol. 38, no. 3, 2023, pp. 112-125.

6. Nuclear Regulatory Commission. Regulatory Guide 1.84: Design, Fabrication, and Materials Code Case Acceptability for Nuclear Power Plant Components. Washington, DC: U.S. NRC, 2022.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise