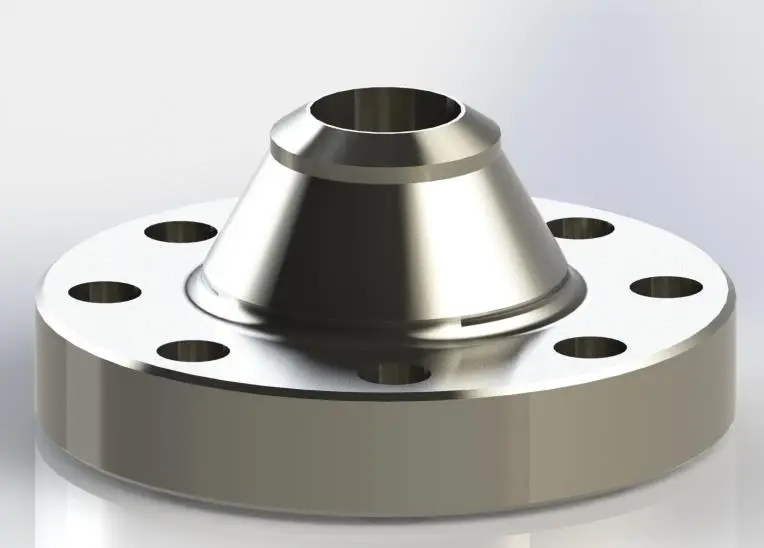

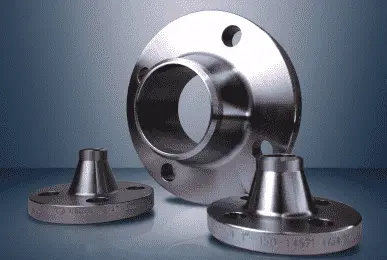

Why are welding neck flanges preferred for offshore oil and gas pipelines?

Some of the most difficult places on Earth are where offshore oil and gas pipes work. When high-pressure, acidic fluids, and constant exposure to seawater come together, they create a perfect storm of stress factors that can weaken pipeline integrity. For these important uses, welding neck flanges are the best option because of how well they are designed and how well they work.

Superior stress distribution

One of the best things about welding neck plates is that they make the joint less stressed all over. The slow change from the flange to the pipe wall makes the flow of forces easier. This lowers stress levels that can cause fatigue and failure. For ocean pipes, this is especially important because wave movement and changes in temperature can cause parts of the pipeline to wear out faster.

Enhanced weld integrity

Full penetration welds, which are stronger and more reliable than other types of flange joints, can be made with welding neck flanges because of the way they are made. This full-strength weld makes the connection between the flange and the pipe smooth, so they work together as one unit. This level of weld quality is necessary to keep people safe and protect the environment in remote settings where a leak could have terrible effects.

Improved flow characteristics

Welding neck flanges have a smooth internal hole that helps the flow of fluids inside the pipeline. This lowers the chance of damage and turbulence, which can be very important in ocean pipes that carry rough materials. Keeping the inside width the same is what welding neck flanges do to help the pipeline stay strong over its entire working life.

Safety and reliability benefits: high fatigue resistance and leak prevention

Because of what could happen if these important systems break down, the safety and dependability of ocean pipes are very important. Welding neck flanges has a number of important advantages that make overseas uses safer and more reliable.

High fatigue resistance

Offshore pipes are always being loaded and unloaded because of waves, changes in temperature, and changes in operating pressure. If you don't handle this stress correctly, it can cause tiredness and failure. Welding neck flanges is the best in this case because they are better at spreading the load. There aren't as many stress concentrations where the joint meets the pipe wall because of the slow change. Stress concentrations are where fatigue cracks usually start.

In addition, the full entry weld used in welding neck flange setups makes the joint stronger, more regular, and less likely to fail because of wear and tear. This better resistance to stress helps the pipeline last longer and means it doesn't need to be maintained or replaced as often, which can be hard and expensive to do in remote settings.

Effective leak prevention

Leak protection is an important part of marine pipeline safety, both for the environment and for the people who work on the pipeline. Neck plates that are welded are better at stopping leaks because of the following:

- When welding neck flanges are put together correctly with the right seals, the raised face form of the sealing surface makes it stronger. This makes sure that the link is tight and doesn't leak.

- Stress spread out evenly: Welding neck flanges lowers the risk of localized warping that could damage the seal's integrity by spreading loads out evenly across the joint.

- Resistance to thermal cycling: Welding neck flanges are less likely to come free because they are integrally designed. This means that they can keep a tight seal even when the temperature changes.

When used abroad, where finding and fixing leaks can be very hard and expensive, these features that stop leaks are especially useful. Welding neck flanges helps protect the environment, keep operations going, and lower the overall costs of ocean pipeline systems over their whole lifetime by lowering the chance of leaks.

Compliance with offshore standards: API 6A, DNV, and ASME codes

As part of your job, you have to follow strict rules to make sure that faraway pipe parts are safe and reliable. API 6A, DNV, and ASME all have rules that welding neck flanges must follow when they are used outside of the United States. There are a lot of strict rules about what can be used, how it should be made, and how it should be checked.

API 6A compliance

Specification 6A from the American Petroleum Institute is a very important rule for wellhead and Christmas tree tools, like flanges used in marine situations. Welding neck flanges made for use abroad must meet the strict standards of API 6A, which includes:

- Choice of materials and quality

- Processes for design and production

- Needs for performance under different temperature and pressure situations

- How to test and inspect things

Following the rules in API 6A ensures that welding neck flanges can handle the rough conditions and high pressures that are typical in oil and gas production off the coast of the United States.

DNV certification

The company Det Norske Veritas (DNV) certifies underwater parts, such as welding neck flanges. In the ocean business, DNV guidelines are generally known and focus on:

- Management and measurement of risk

- Strength of the structure and reaction to tiredness

- How to stop corrosion and choose the right materials

- Processes for quality control and security

Welding neck flanges that meet DNV approval standards shows that they can be used in harsh ocean settings and that they can stay safe and reliable for long periods of time.

ASME code compliance

There are important rules for planning and making pressure vessels in Section VIII, Division 1 of the Boiler and Pressure Vessel Code from the American Society of Mechanical Engineers (ASME). These rules cover things like welding neck flanges and other parts of pipes. In line with ASME standards,

- Correct estimates for the plan and a strength study

- The right choice of materials and heat treatment

- How to weld and what skills you need

- Needs for testing and inspection

When welding neck flanges that are made according to ASME codes, you can be sure that they can safely hold pressure and handle the practical loads that come up in remote pipes.

Boat pipe welding neck flanges that follow these strict rules and guidelines show that they care about safety, trustworthiness, and performance. By following the guidelines set by API 6A, DNV, and ASME, these important parts are planned, built, and tested to be able to handle the unique problems that come up in offshore settings. This helps keep offshore pipeline systems safe and sound overall.

Conclusion

Welding neck flanges are a big part of making ocean lines safer. They are well-made, can spread stress evenly, and have to meet strict industry standards. They keep buried pipe systems together and make them last a long time by making them less likely to break, stopping leaks, and being able to stand up to the bad ocean weather. In the naval oil and gas business, strong and reliable parts like welding neck flanges are very important because they are used in tough conditions.

If EPC contractors, suppliers, and end-users in the industry want to lower project risk, make sure safety rules are followed, and get uniform quality, they need to make sure they choose the right welding neck flanges. The welding neck flanges and other industrial pipe fittings made by Hebei Rayoung Pipeline Technology Co., Ltd. are of high quality and are made to work in the toughest situations abroad. Since we are certified by GOST-R and SGS for quality, we can help you with your important pipeline projects in a way that works well, is safe, and lasts a long time.

Don't skimp on safety and dependability when it comes to your ocean pipeline systems. Talk to RAYOUNG right away to learn more about our welding neck flanges and how we can assist you with your job. We can help you pick out the right parts so that your trips are safe and stress-free.

FAQ

1. What materials are commonly used for welding neck flanges in offshore applications?

Nickel alloys, carbon steel with the right finishes, or stainless steel (316L, duplex, or super duplex types) can be used to make welding neck flanges in rural areas. These don't rust. It depends on how the machine is used, the fluid it uses, how hot it is underground, and what kind of material is used.

2. How do welding neck flanges compare to slip-on flanges for offshore use?

On most occasions, welding neck flanges are better for naval use than slip-on flanges. This is because they better spread stress, stop wear, and protect the weld. It is safer and works better in rough ocean conditions to weld neck flanges instead of slip-on flanges in the long run.

3. What factors should be considered when selecting welding neck flanges for offshore pipelines?

Need welding neck plates for pipes in the ocean? Think about the pressure and temperature that will be used, the type of fluid, the climate (like being near saltwater), the standards (API, DNV, ASME), how well the materials work together, how well they don't rust, and what you need for your project or installation. Also, you should only buy flanges from a company you know will give you high-quality ones that meet or go above and beyond what the industry requires.

Ensure Offshore Pipeline Safety with Premium Welding Neck Flanges | RAYOUNG

Are you ready for your naval wire projects to be safer and work better? Some welding neck flanges are made to be used in other countries, where the rules are very strict. They come in many different styles. There are strict rules that our products must follow, such as those set by API 6A, DNV, and ASME. There aren't many risks in our project because we only use good parts and know a lot about how they work. This project will go on for a long time, even if the sea is rough. That's something we can help you do. You shouldn't guess about how safe your water line is. Contact us today at info@hb-steel.com to discuss your specific needs and discover how our welding neck flanges can contribute to the success of your offshore operations.

References

1. American Petroleum Institute. (2018). Specification for Wellhead and Christmas Tree Equipment. API Specification 6A.

2. DNV GL. (2020). Offshore Standards for Piping Systems and Components. DNVGL-OS-E201.

3. ASME. (2019). Boiler and Pressure Vessel Code, Section VIII, Division 1: Rules for Construction of Pressure Vessels. American Society of Mechanical Engineers.

4. Bai, Y., & Bai, Q. (2018). Subsea Engineering Handbook. Gulf Professional Publishing.

5. Palmer, A. C., & King, R. A. (2008). Subsea Pipeline Engineering. PennWell Books.

6. Nayyar, M. L. (2000). Piping Handbook. McGraw-Hill Education.