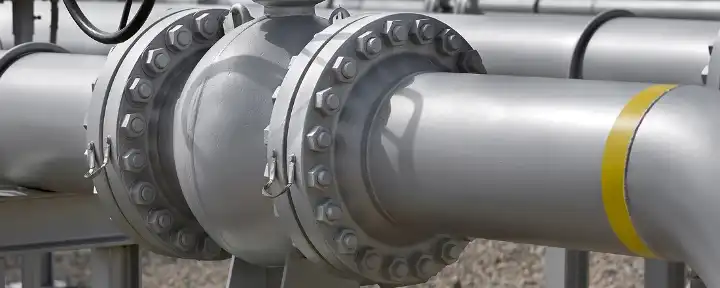

China's slip-on flanges are now important parts of Kyrgyzstan's growing pipeline network, providing strong solutions for systems that carry oil, gas, and water. These flanged connections are a solid way to connect pipeline sections. They let you put a pipe directly into the flange bore without needing specific tools to install it. Slip-on flanges are designed to make strong pipe connections that can handle the high pressure and temperature changes that are common in Central Asian pipeline conditions. This keeps leaks and structural failures from happening over long periods of time.

Understanding Slip-On Flanges: Specifications, Types, and Applications

Pipeline flange components represent essential connecting elements in modern infrastructure projects across Kyrgyzstan's challenging terrain. The fundamental design principle behind these flanged fittings involves a straightforward approach where pipes slide directly into the flange bore, creating a secure foundation for welding operations.

Material Specifications and Standards

Chinese manufacturers produce flanged connections using various high-grade materials tailored to specific operational requirements. Carbon steel flanges dominate applications requiring cost-effective solutions while maintaining structural integrity. Stainless steel variants provide enhanced corrosion resistance essential for harsh environmental conditions. Alloy steel options deliver superior strength characteristics for high-pressure applications exceeding standard operational parameters.

International standards set the rules for how things should be made, making sure that all pipeline systems around the world can work together. For North American applications, ANSI B16.5 sets size requirements, while for larger diameter installations, ASME B16.47 sets size requirements. European DIN standards offer alternative specifications that are commonly accepted in Central Asian markets. This gives you more options for planning projects and buying things.

Pressure Rating Classifications

Pressure ratings determine application suitability across diverse operational environments. Class 150 flanges accommodate low-pressure systems typical in water distribution networks. Class 300 and 600 ratings serve medium-pressure gas transmission lines prevalent in regional infrastructure. Class 900 and 1500 variants handle high-pressure applications requiring enhanced structural performance under extreme conditions.

Applications in Kyrgyzstan Pipeline Networks

Local pipeline projects benefit from slip-on flanges versatility across multiple sectors. Natural gas distribution systems utilize these components for main transmission lines and distribution branches. Water infrastructure projects incorporate corrosion-resistant variants for municipal supply networks. Industrial applications leverage high-pressure ratings for process piping systems in manufacturing facilities.

Technical Comparison: Slip-On Flanges vs Other Flange Types

Understanding performance differences between flange types enables informed selection decisions for specific project requirements. Each design offers distinct advantages depending on operational parameters and installation constraints.

Structural Design Differences

Weld neck flanges provide superior strength through integral neck extensions that distribute stress more effectively. However, slip-on designs offer simplified installation procedures while maintaining adequate performance for moderate pressure applications. Lap joint flanges allow bolt adjustment flexibility but require additional stub end components, increasing system complexity and costs.

Threaded connections eliminate welding requirements but compromise pressure capacity and long-term reliability. Socket weld variants combine ease of installation with improved strength characteristics but limit pipe positioning flexibility during assembly operations.

Pressure Tolerance Considerations

Performance under pressure varies significantly between flange types, influencing selection criteria for specific applications. Slip-on designs accommodate moderate pressure ranges effectively while offering cost advantages over more complex alternatives. This balance makes them particularly suitable for Kyrgyzstan's pipeline conditions where temperature fluctuations and moderate pressures dominate operational requirements.

Installation and Maintenance Factors

Installation simplicity represents a key advantage driving slip-on flange popularity in remote locations common throughout Kyrgyzstan. Reduced welding complexity minimizes field installation time and skill requirements. Maintenance accessibility remains excellent due to standardized bolt patterns and gasket replacement procedures.

Procurement Guide: Sourcing Quality Slip-On Flanges from China

Successful procurement requires systematic evaluation of supplier capabilities and quality assurance processes. Chinese manufacturers have established robust production systems meeting international standards while offering competitive pricing structures.

Supplier Evaluation Criteria

Quality certifications provide fundamental indicators of manufacturing capability and process control. ISO 9001:2015 certification demonstrates commitment to quality management systems. ASME certification ensures compliance with American pressure vessel standards. API certification validates suitability for petroleum industry applications common in regional projects.

Production capacity assessment helps determine supplier ability to meet project timelines and volume requirements. Modern facilities equipped with CNC machining capabilities deliver consistent dimensional accuracy. Heat treatment facilities ensure proper material properties throughout the product range.

Pricing Structure Analysis

Chinese suppliers typically offer competitive pricing through efficient manufacturing processes and material sourcing advantages. Volume-based pricing tiers reward larger orders with significant cost reductions. Customization capabilities accommodate specific project requirements for slip-on flanges without excessive premium charges.

Minimum order quantities vary between suppliers but generally remain reasonable for medium-scale projects. Shipping consolidation options help reduce transportation costs for multiple item orders. Payment terms flexibility supports various procurement budgeting approaches.

Technical Support Services

Leading Chinese manufacturers provide comprehensive technical assistance throughout the procurement process. Engineering support includes material selection guidance and application-specific recommendations. Documentation packages include detailed drawings, material certificates, and test reports ensuring compliance verification.

Installation, Welding, and Maintenance of Slip-On Flanges

Proper installation procedures maximize performance and service life while ensuring operational safety throughout the pipeline system. Welding quality directly impacts long-term reliability under varying operational conditions.

Pre-Installation Inspection

Visual inspection identifies potential defects before installation begins. Surface condition assessment ensures proper weld preparation. Dimensional verification confirms compatibility with existing pipeline components. Material certification review validates grade specifications match project requirements.

Welding Procedures and Standards

ASME Section IX provides welding procedure specifications ensuring consistent joint quality. AWS D1.1 standards govern structural welding requirements for pipeline applications. Qualified welders must demonstrate competency through standardized testing procedures.

Heat input control prevents material property degradation during welding operations. Post-weld heat treatment may be required for certain material grades and thickness ranges. Non-destructive testing validates weld integrity before system pressurization.

Maintenance Best Practices

Regular inspection schedules identify potential issues before failure occurs. Corrosion monitoring programs track degradation rates in aggressive environments. Gasket replacement intervals depend on service conditions and material compatibility.

Kyrgyzstan's climate presents specific challenges including temperature cycling and moisture exposure. Protective coating systems extend service life in harsh environmental conditions. Documentation systems track maintenance history supporting reliability analysis and replacement planning.

RAYOUNG: Your Trusted Slip-On Flange Manufacturer

RAYOUNG has established itself as a leading manufacturer of high-quality flanged fittings serving the global pipeline industry. Our comprehensive product range includes diverse industrial pipe fittings such as buttweld steel elbows, steel reducers, and various flange configurations ensuring secure connection points across all pipeline applications.

Product Range and Capabilities

Our manufacturing capabilities span the complete spectrum of flanged connection requirements. Carbon steel pipe fitting solutions deliver reliable performance for standard applications while maintaining cost effectiveness. Specialized alloy compositions accommodate extreme service conditions common in industrial environments.

Quality certifications include GOST-R and SGS validation ensuring export compliance and performance verification. ISO 9001:2015 certification demonstrates our commitment to consistent quality management throughout all production processes. These credentials provide confidence for international projects requiring documented quality assurance.

Service Excellence

Technical consulting services help optimize component selection for specific project requirements, including the best options for slip-on flanges. Engineering support includes application analysis and performance predictions under various operating conditions. Customization capabilities accommodate unique specifications without compromising delivery schedules.

Global shipping networks ensure reliable delivery to remote project locations throughout Central Asia. Quality documentation packages include material certificates, dimensional reports, and test results supporting project compliance requirements.

Conclusion

China's slip-on flanges provide reliable, cost-effective solutions for Kyrgyzstan's expanding pipeline infrastructure. These components offer excellent performance characteristics while maintaining installation simplicity crucial for remote project locations. Proper supplier selection, quality verification, and installation procedures ensure optimal performance throughout extended service periods. Chinese manufacturers like RAYOUNG deliver comprehensive solutions combining competitive pricing with technical excellence, supporting successful pipeline development across Central Asia's challenging operational environment.

Frequently Asked Questions

Q1: How do slip-on flanges comply with international pipeline standards?

A: Slip-on flanges manufactured to ANSI B16.5, ASME B16.47, or DIN standards automatically comply with international pipeline requirements. These standards specify dimensional tolerances, material properties, and pressure ratings ensuring compatibility across global pipeline systems. Chinese manufacturers maintain strict adherence to these specifications through certified quality management systems.

Q2: What factors influence pressure rating selection for Kyrgyzstan pipeline projects?

A: Pressure rating selection depends on maximum operating pressure, temperature range, safety factors, and local regulations. Kyrgyzstan's pipeline systems typically operate at moderate pressures suitable for Class 150 to Class 600 flanges. Environmental factors including temperature cycling and seismic activity influence rating requirements.

Q3: What are typical lead times for custom slip-on flange orders from China?

A: Standard configurations typically ship within 2-4 weeks depending on quantity and material availability. Custom specifications require 4-8 weeks including engineering review, material procurement, and manufacturing. Expedited production options may be available for urgent project requirements with appropriate scheduling coordination.

Partner with RAYOUNG for Your Pipeline Flange Needs

Ready to source premium slip-on flanges for your Kyrgyzstan pipeline project? RAYOUNG combines decades of manufacturing expertise with comprehensive technical support to deliver solutions meeting your exact specifications. Our certified production facilities and quality assurance programs ensure reliable performance under the most demanding conditions. Whether you need standard configurations or custom engineered solutions, our experienced team provides guidance throughout the procurement process. Contact us at info@hb-steel.com to discuss your project requirements and receive detailed quotations from a trusted slip-on flanges supplier committed to your project success.

References

1. American Society of Mechanical Engineers. "ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." New York: ASME Press, 2020.

2. International Organization for Standardization. "ISO 7005-1:2011 Metallic flanges - Part 1: Steel flanges." Geneva: ISO Publications, 2011.

3. China National Petroleum Corporation. "Pipeline Construction Standards for Central Asian Gas Projects." Beijing: CNPC Technical Standards Committee, 2019.

4. Kyrgyzstan Ministry of Energy. "National Pipeline Infrastructure Development Plan 2020-2030." Bishkek: Government Publishing Office, 2020.

5. American Welding Society. "AWS D1.1/D1.1M Structural Welding Code - Steel." Miami: AWS Technical Publications, 2020.

6. China Steel Industry Association. "Quality Standards for Export Pipeline Components." Beijing: Metallurgical Industry Press, 2021.