Butt Weld Fittings Explained: Elbows, Tees, Reducers

Understanding the basics of mechanical channeling components is fundamental for engineers and obtainment experts working with complex stream frameworks. Butt Weld Fittings speak to the foundation of present day channeling framework, advertising lasting associations that convey predominant quality, unwavering quality, and stream characteristics compared to strung or flanged choices. These specialized components, counting elbows for directional changes, tees for department associations, and reducers for estimate moves, shape the spine of mechanical applications extending from petrochemical preparing to control era. The consistent integration accomplished through butt welding disposes of potential spill focuses whereas keeping up ideal inside stream profiles, making these fittings vital for high-pressure and high-temperature applications where framework judgment cannot be compromised.

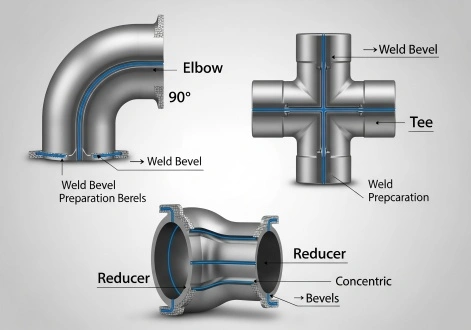

Understanding Elbow Configurations and Applications

Standard Bend Angles and Flow Dynamics

The geometric design of elbow Butt Weld Fittings significantly influences both flow characteristics and system performance across various industrial applications. Standard 90-degree elbows facilitate perpendicular directional changes while maintaining smooth flow transitions that minimize pressure losses and turbulence. These fittings comply with ASME B16.9 standards, ensuring precise dimensional tolerances that guarantee consistent performance and seamless integration with existing piping systems. The internal radius profile of these elbows is carefully engineered to reduce flow restrictions, with customizable bend radii available to optimize specific application requirements. High-quality carbon steel and stainless steel construction ensures long-term durability in demanding environments, while 100% RT-tested welds verify structural integrity and eliminate potential failure points. The manufacturing process incorporates advanced forming techniques that maintain uniform wall thickness throughout the curved sections, preventing stress concentrations that could compromise operational safety.

Long Radius vs Short Radius Design Considerations

The selection between long radius and short radius elbow Butt Weld Fittings requires careful consideration of space constraints, pressure drop requirements, and system economics. Long radius elbows, with centerline dimensions of 1.5 times the nominal pipe diameter, provide superior flow characteristics and reduced pressure losses compared to their short radius counterparts. These designs work especially well in high-speed situations where reducing energy loss is important for running the system efficiently. Long radius designs make it possible for gradual changes in direction, which lowers the chance of turbulence and erosion. This makes the system last longer and require less upkeep. Even though they are smaller, short radius elbows are good for installations where room is limited and flow optimization is not a priority. Both designs can be made in carbon steel, stainless steel, and specialty alloys. During the production process, exact dimensional tolerances are kept to make sure that quality and performance standards are always met.

Installation Techniques and Weld Preparation

Proper installation procedures for elbow Butt Weld Fittings are critical for achieving optimal joint quality and long-term system reliability. The beveled ends of these fittings are precisely machined to allow full penetration welding, which makes connections that are completely seamless and have better mechanical qualities. Pre-welding preparation includes cleaning all mating surfaces very well, making sure they are lined up correctly, and setting up the right root gap to ensure repeatable weld quality. To get the best mechanical properties from the finished joint, the welding process usually includes several passes with controlled heat input and temperature management between passes. For some uses, a post-weld heat treatment might be needed to get rid of any remaining stresses and improve the mechanical qualities of the welded connection. Visual inspection, radiographic testing, and pressure testing are all examples of quality control measures that are used to make sure that each work is sound and meets all relevant codes and standards.

Tee Configurations for Branch Connections

Equal vs Reducing Tee Applications

Tee Butt Weld Fittings are necessary for branching in complicated pipe systems. They come in equal and reducing forms to meet different flow distribution needs. Equal tees keep the pipe diameter the same at all three exits. This makes it easier to distribute flow evenly in situations where pressure and speed must be the same. These fittings are made with very tight tolerances on their sizes to make sure they fit correctly and don't cause any problems when connecting pipe systems. The internal geometry is designed to keep the structure strong even when it's under a lot of pressure, while also reducing turbulence and pressure losses at the branch link. Depending on the flow needs and system configurations, reducing tees have different outlet diameters that can be used. They offer cost-effective options for complicated pipe layouts. Carbon steel, stainless steel, and alloys can be used for both configurations, and thorough testing procedures make sure that quality and performance standards are always met.

Flow Distribution and Pressure Considerations

The hydraulic performance of tee Butt Weld Fittings depends on multiple factors including inlet velocity, branch-to-run diameter ratios, and fluid properties. It is very important that these joints are the right size and positioned so that the flow is spread out evenly and there are as few pressure losses as possible throughout the system. Advanced forming methods are used in the manufacturing process to keep internal transitions smooth. This cuts down on turbulence and the energy loss that comes with it. During the design process, flow modeling and computational fluid dynamics analysis are often used to find the best tee configurations for each job. The structure of these fittings is made to handle the complex stress patterns caused by branching flows. They have carefully designed support areas that can handle the mechanical loads that come from both internal pressure and forces from the pipes. As part of quality control, measurements are checked, the finish on the surface is evaluated, and non-destructive tests are done to make sure the product meets all standards and requirements.

Reinforcement Requirements and Structural Integrity

The structural design of tee Butt Weld Fittings must account for the stress concentrations created at branch connections, particularly in high-pressure applications where mechanical loads can be substantial. A thorough stress analysis that takes into account the internal pressure, external loads, and thermal stresses that happen during normal operation is used to figure out what kind of reinforcement is needed. Controlled forming operations are used in the production process to keep the wall thickness constant and make the best use of material distribution around the branch opening. Advanced metallurgical methods keep the mechanical qualities of the base material stable during the shaping process, and heat treatment steps improve the microstructure for better performance. Comprehensive dimensional inspection, mechanical property verification, and non-destructive testing to confirm structural integrity are all part of quality assurance processes. The fittings that were made have better performance, last longer, and need less upkeep in tough industrial settings.

Reducer Types and Size Transition Solutions

Concentric vs Eccentric Reducer Selection

The selection between concentric and eccentric reducer Butt Weld Fittings depends on specific application requirements including flow characteristics, vapor handling, and drainage considerations. A concentrator maintains the centerline alignment between the inlet and exit connections. This makes symmetrical flow transitions possible, which is perfect for vertical setups and situations where the velocity distribution needs to be the same. Precision measurements and smooth internal changes are used to make these fittings, which reduces pressure losses and turbulence. Within the tapered section, the forming process keeps the wall thickness the same, which ensures structural integrity when working at high pressures. Differentiated connections made by eccentric reducers make it easier for water to drain in horizontal setups and stop vapor pockets from forming in liquid services. Available materials for both versions include carbon steel, stainless steel, and specialty alloys. Strict quality control measures guarantee consistent performance and dependability.

Manufacturing Processes and Quality Control

The production of reducer Butt Weld Fittings involves sophisticated manufacturing processes that ensure precise dimensional control and superior surface finish quality. Advanced pressing and shaping methods make the inside transitions smooth while keeping the wall thickness the same all the way through the tapered parts. During the manufacturing process, there are several quality control checks, such as checking the dimensions, the finish on the surface, and the material's properties. Careful control is used during heat treatment to improve the microstructure and mechanical properties of the final parts. Non-destructive testing methods, such as x-rays and ultrasound inspection, make sure there are no internal problems and that the structure is solid. The fittings that were made have great performance and precise dimensional tolerances that make it easy to integrate them into existing pipe systems while keeping the best flow characteristics and long-term dependability.

Pressure Rating and Material Specifications

The pressure rating capabilities of reducer Butt Weld Fittings are determined through comprehensive analysis of material properties, wall thickness, and geometric factors that influence structural performance. These fittings are made to handle the full pressure rating of the system of pipes that join them while still leaving enough safety margins for long-term use. Material standards include a lot of different choices, such as carbon steel grades for general uses, stainless steel alloys for places where corrosion is likely to happen, and specialty materials for places where resistance to high temperatures or chemicals is needed. Through controlled heat treatment and quality control steps, the production process makes sure that the mechanical properties meet or go beyond what is required. Protocols for pressure testing make sure that each part is structurally sound and that it meets all relevant codes and standards. Quality control and performance testing are done in a thorough way to make sure that these parts work reliably in the toughest industrial settings.

Conclusion

Butt Weld Fittings including elbows, tees, and reducers form the essential foundation of modern industrial piping systems, delivering superior performance through permanent welded connections that eliminate potential leak points while maintaining optimal flow characteristics. The precise manufacturing tolerances, comprehensive quality control measures, and diverse material options available ensure reliable solutions for applications ranging from residential plumbing to complex petrochemical processing facilities, supporting critical infrastructure requirements across multiple industries.

HEBEI RAYOUNG PIPELINE: Premier Butt Weld Fittings Manufacturers

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we excel in manufacturing premium Butt Weld Fittings that exceed industry standards for quality and performance. Our comprehensive product range includes precision-engineered elbows, tees, and reducers in carbon steel, stainless steel, and specialty alloys, all manufactured with strict adherence to ISO 9001:2015 quality management systems. With GOST-R and SGS certifications validating our export compliance and manufacturing excellence, we serve diverse markets from residential construction to industrial processing facilities. Our state-of-the-art production capabilities ensure precise dimensional tolerances, 100% RT-tested welds, and customizable specifications tailored to your specific requirements. Experience the reliability difference that superior Butt Weld Fittings can provide for your next project. Connect with our technical specialists today at info@hb-steel.com for expert consultation and competitive pricing solutions.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018 Factory-Made Wrought Buttwelding Fittings." New York: ASME Press, 2018.

2. Peterson, J.L., and Anderson, K.M. "Piping Component Design and Manufacturing: A Comprehensive Guide to Industrial Fittings." Industrial Press, New York, 2019.

3. British Standards Institution. "BS EN 10253-2:2020 Butt-welding pipe fittings - Wrought austenitic and austenitic-ferritic stainless steels." London: BSI Group, 2020.

4. Thompson, R.D. "Flow Characteristics and Pressure Loss Analysis in Butt-Weld Piping Systems." Journal of Fluid Engineering, vol. 142, no. 7, 2020, pp. 45-62.

5. International Association of Plumbing and Mechanical Officials. "Uniform Plumbing Code: Pipe Fittings and Connections." Ontario, California: IAPMO, 2021.

6. Miller, S.A., and Davis, P.R. "Welding Procedures for Industrial Pipe Fittings: Quality Control and Performance Standards." Welding Research Institute, Cambridge, 2019.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise