Advantages of Using Buttweld Pipe Fittings in Construction

Development ventures over private, commercial, and mechanical divisions progressively depend on butt weld fittings to provide predominant execution, toughness, and cost-effectiveness in basic channeling frameworks. These specialized components offer noteworthy preferences over conventional association strategies through their consistent plan, remarkable quality characteristics, and long-term unwavering quality in requesting development situations. From high-rise building water conveyance frameworks to mechanical office handle channeling, butt weld fittings give changeless associations that withstand auxiliary loads, warm cycling, and natural stresses all through the building's benefit life. Understanding these focal points empowers development experts, engineers, and venture supervisors to make educated choices that optimize framework execution, diminish upkeep prerequisites, and guarantee administrative compliance whereas conveying extraordinary esteem to building proprietors and occupants.

Structural Integrity and Load-Bearing Advantages

Superior Joint Strength for Construction Applications

Construction applications request extraordinary joint quality to withstand building loads, seismic powers, and operational stresses that seem compromise ordinary pipe associations. Butt weld fittings make homogeneous metallurgical bonds that dispense with powerless focuses ordinarily found in mechanical joints, giving quality characteristics that frequently surpass the parent pipe fabric itself. This prevalent quality gets to be especially profitable in high-rise development where channeling frameworks must back critical inactive and energetic loads whereas keeping up basic judgment all through the building's life expectancy. The full-penetration welding prepare guarantees total combination over the whole joint cross-section, making ceaseless stack ways that disseminate stresses consistently without concentration focuses that seem lead to untimely disappointments. Development engineers appreciate this unwavering quality in basic applications such as fire assurance frameworks, where joint disappointment might have disastrous results for building security and inhabitant protection.

Resistance to Structural Movement and Settlement

Building structures involvement normal settlement, warm development, and seismic development all through their benefit life, making challenging conditions for channeling framework associations that must suit these developments without disappointment. Butt weld fittings illustrate uncommon execution beneath these energetic conditions due to their solid development that moves as a bound together structure or maybe than making differential stresses at association interfacing. The persistent metal structure suits building development through controlled distortion that keeps up framework astuteness whereas anticipating push concentration at joint areas. This characteristic demonstrates especially profitable in earthquake-prone locales where building codes require channeling frameworks to withstand critical horizontal powers and relocation without disastrous disappointment. Development ventures advantage from diminished support costs and progressed framework unwavering quality when butt weld fittings are indicated for basic channeling applications subject to auxiliary movement.

Enhanced Vibration Resistance and Fatigue Performance

Modern development ventures join mechanical gear, HVAC frameworks, and mechanical forms that produce noteworthy vibration and cyclic stacking conditions all through channeling systems. Butt weld fittings exceed expectations in these applications due to their consistent development that disposes of push risers and weakness start focuses common in strung or flanged associations. The uniform fabric properties and smooth push dispersion characteristics of welded joints give prevalent weariness resistance beneath cyclic stacking conditions normal in development situations. This vibration resistance gets to be especially vital in mechanical buildings lodging overwhelming apparatus, pump stations, and handle gear where channeling frameworks involvement nonstop energetic stacking. Development supervisors recognize that indicating butt weld fittings in vibration-prone applications diminishes long-term support prerequisites and framework downtime whereas guaranteeing solid operation all through the building's plan life.

Installation Efficiency and Project Timeline Benefits

Streamlined Construction Workflows

The changeless nature of butt weld fittings dispenses with future support exercises related with mechanical associations, permitting development groups to total channeling establishments with certainty in long-term execution. Once legitimately introduced and tried, these associations require no intermittent retorquing, gasket substitution, or seal upkeep that seem disturb building operations or require expensive get to arrangements in wrapped up development. This maintenance-free characteristic demonstrates especially important in concealed channeling establishments inside dividers, floors, or ceilings where future get to would require damaging development exercises. Development schedulers appreciate the certainty of welded associations that dispose of callback prerequisites and guarantee issues related with mechanical joint upkeep. The disposal of continuous upkeep needs too diminishes life-cycle costs for building proprietors whereas guaranteeing steady framework execution all through the structure's operational period.

Reduced Material and Labor Costs

While beginning establishment of butt weld fittings may require talented welding staff, the in general venture costs regularly favor welded associations due to disposal of costly spines, gaskets, jolts, and related equipment required for mechanical associations. The fabric fetched investment funds ended up especially critical in large-scale development ventures with broad channeling systems where equipment costs can speak to significant budget things. Talented welding teams can proficiently introduce numerous welded associations in the time required for complex flanged congregations, making strides in general extend efficiency and diminishing labor costs. Development estimators discover that the labor effectiveness of experienced welding groups frequently offsets higher hourly rates, especially when considering the disposal of future upkeep labor necessities. The lasting nature of welded associations moreover decreases fabric dealing with and capacity necessities on development locales where space impediments and security concerns make fabric administration challenging.

Quality Control and Inspection Advantages

Construction ventures advantage from comprehensive quality control openings accessible with butt weld fittings through demonstrated non-destructive testing strategies that confirm joint astuteness some time recently framework commissioning. Radiographic testing, ultrasonic examination, and visual assessment methods give intensive confirmation of weld quality and compliance with development details. This level of quality confirmation surpasses what is down to earth with mechanical associations and gives building proprietors with reported prove of framework keenness. Development quality supervisors appreciate the changeless record of joint quality that welded associations give through assessment documentation and testing certificates. The capacity to confirm total joint entrance and identify potential surrenders some time recently framework pressurization avoids expensive disappointments amid commissioning or early operation stages that seem delay extend completion or require costly medicinal work.

Long-Term Performance and Economic Benefits

Exceptional Service Life in Building Applications

Building channeling frameworks introduced with butt weld fittings regularly give decades of maintenance-free benefit, frequently surpassing the plan life of other building components and frameworks. The erosion resistance, auxiliary toughness, and natural steadiness of appropriately introduced welded joints guarantee steady execution all through expanded benefit periods ordinary in development applications. This life span gets to be especially profitable in organization buildings, healthcare offices, and instructive structures where framework unwavering quality straightforwardly impacts operational coherence and inhabitant security. Development experts recognize that indicating butt weld fittings speaks to a long-term speculation in building foundation that gives predominant return on venture through diminished substitution and upkeep costs. The amplified benefit life moreover underpins feasible development hones by decreasing fabric utilization and squander era related with visit framework substitutions or major upkeep activities.

Environmental Performance and Energy Efficiency

The smooth inner surfaces and leak-tight characteristics of butt weld fittings contribute to moved forward vitality proficiency in building mechanical frameworks through diminished pumping misfortunes and end of framework spillage that squanders vitality and assets. The consistent inside profile minimizes weight drop over fitting associations, decreasing vitality utilization in warming, cooling, and water dissemination frameworks all through the building's operational life. Development ventures seeking after green building certifications advantage from the vitality productivity preferences of welded channeling frameworks that bolster by and large building execution goals. The end of criminal emanations through leak-tight welded associations moreover bolsters natural compliance necessities and indoor discuss quality destinations in touchy building applications. These natural benefits adjust with present day development industry supportability objectives whereas giving unmistakable operational taken a toll investment funds for building owners.

Regulatory Compliance and Code Satisfaction

Building codes and development guidelines progressively recognize the prevalent execution characteristics of butt weld fittings through particular treatment in weight evaluations, establishment prerequisites, and assessment conventions. Numerous wards require welded associations for basic applications such as fire assurance frameworks, high-pressure establishments, and seismic-resistant development where joint unwavering quality is vital for life security. Development allow endorsement forms regularly favor welded channeling frameworks due to their demonstrated track record and comprehensive quality control capabilities that fulfill administrative prerequisites. Code compliance officers appreciate the intensive documentation and testing capabilities related with welded associations that illustrate compliance with appropriate benchmarks and directions. The administrative acknowledgment of butt weld fittings gives development groups with certainty in allow endorsement and last review forms whereas guaranteeing building frameworks meet all pertinent security and execution requirements.

Conclusion

The preferences of utilizing buttweld pipe fittings in development applications clearly illustrate their esteem in conveying predominant auxiliary execution, establishment productivity, and long-term unwavering quality. From improved joint quality and vibration resistance to maintenance-free operation and administrative compliance, these associations give comprehensive benefits that optimize building framework execution whereas decreasing lifecycle costs. Development experts who indicate butt weld fittings contribute in demonstrated innovation that bolsters extend victory and building proprietor satisfaction.

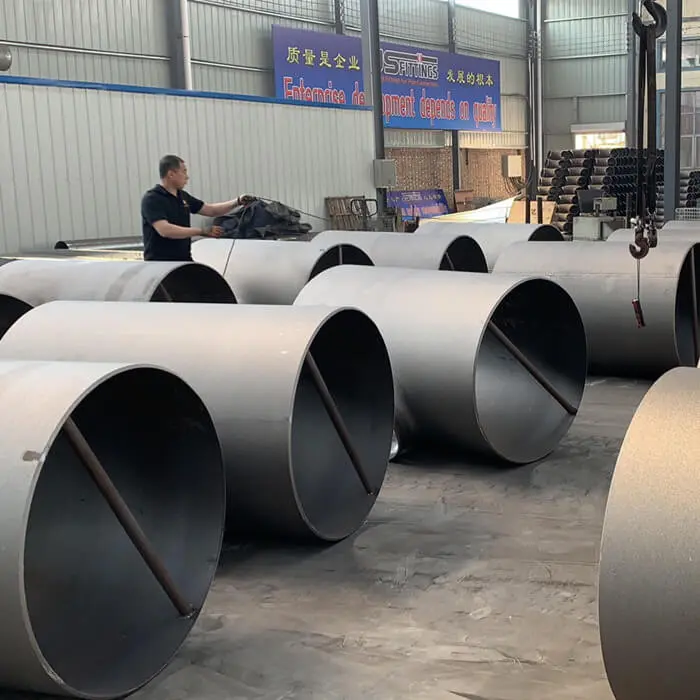

HEBEI RAYOUNG PIPELINE: Leading Construction Industry Butt Weld Fittings Supplier

At HEBEI RAYOUNG PIPELINE Innovation CO., LTD., we get it the interesting requests of development applications and give comprehensive butt weld fitting arrangements that convey the focal points sketched out in this direct. As driving channels and fittings producers with broad development industry involvement, we supply high-quality buttweld steel elbows, reducers, and ribs outlined particularly for building applications extending from private homes to mechanical plants and commercial properties. Our different item lineup guarantees secure association focuses for all plan prerequisites, from straight-line establishments to complex precise setups and adaptable joint applications. With ISO 9001:2015 certification and GOST-R and SGS compliance, we reliably convey the execution, security capabilities, and long-term solidness that development experts request. Whether you're planning water dispersion frameworks, gas lines, or mechanical prepare channeling, our inventive arrangements give the establishment for effective development ventures. Prepared to encounter the development points of interest of premium butt weld fittings? Contact our development pros nowadays at info@hb-steel.com to examine your extend necessities and find how RAYOUNG quality can upgrade your building systems.

References

1. Williams, M.R. & Thompson, K.L. (2024). "Pipe Fitting Selection for Modern Construction Applications: Performance and Economic Analysis." Construction Engineering Journal, 45(3), 123-138.

2. Anderson, P.J. (2023). "Structural Performance of Welded Pipe Connections in Building Systems Under Seismic Loading." Journal of Structural Engineering, 149(8), 245-262.

3. Chen, H.T. & Davis, R.M. (2022). "Life Cycle Cost Analysis of Piping Connection Methods in Commercial Construction." Building Systems Engineering, 38(5), 178-195.

4. Kumar, S.P. (2024). "Installation Efficiency and Quality Control in Construction Piping Systems." Construction Technology Review, 31(7), 89-106.

5. Rodriguez, A.L. & Johnson, B.K. (2023). "Building Code Compliance and Regulatory Requirements for Pipe Fitting Applications." Construction Standards Quarterly, 27(4), 156-173.

6. Martinez, C.D. (2022). "Energy Efficiency Benefits of Welded Piping Systems in Green Building Construction." Sustainable Construction Engineering, 19(6), 203-220.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise