In which service conditions is a slip-on flange preferred over a weld-neck flange?

Slip-on flanges are sometimes better than weld neck flanges because they can do some things better. You need to know these things about pipe systems in order to get the best design and results from them.

Low-pressure and low-temperature applications

Slip-on flanges are a great choice for places where requirements for pressure and temperature are modest. Usually, these factors are:

- Systems for distributing water

- HVAC pipes

- Steam lines with low pressure

- Industrial pipes for general use

Slip-on flanges are enough to keep the seals in place in these less difficult cases because they are easy to make. This choice saves money without lowering safety standards.

Systems requiring frequent maintenance or modifications

Slip-on flanges are a great way to connect lines that need to be taken apart and fixed, cleaned, or changed often.

- Simpler to take apart and put back together

- Not as much downtime during repair tasks

- Ability to make changes or updates to the system in the future

Because they are so flexible, slip-on flanges are very useful in fields where processes change often or where equipment needs to be checked often.

Applications with space constraints

Slip-on flanges are a useful option for places where welding tools can't get to easily:

- Small systems of machinery

- Adding on to current systems

- Industrial areas with a lot of people

When compared to weld neck flanges, sliding the flange onto the pipe and doing a simple fillet weld makes fitting in tight spaces a lot easier.

Cost and installation trade-offs: choosing slip-on for low-stress runs

When looking at how much pipe systems cost and how quickly they can be installed, slip-on flanges are often the best option for low-stress situations. This part talks about the functional and financial benefits of choosing slip-on flanges in these situations.

Initial cost savings

Slip-on flanges typically offer significant cost advantages over weld neck flanges:

- Lower material costs due to simpler design

- Lower production costs due to less complicated manufacturing

- Standardization could lead to savings for buying in bulk.

If money is tight or there are a lot of parts that need to be linked, saving early can make a big difference in how much the whole job costs.

Reduced installation time and labor

Most of the time, fitting slip-on flanges is faster and takes less work:

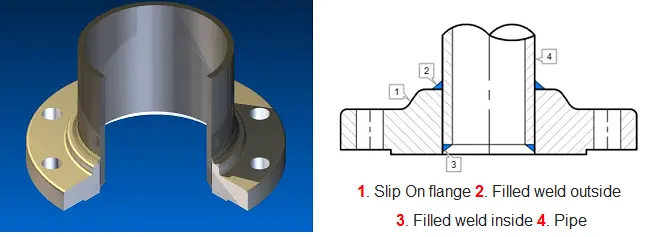

- Less complicated welding needs (two edge welds instead of a full entry join)

- Less precise pipe end preparation is needed

- Easier alignment during assembly

- Most of the time, fitting slip-on flanges is faster and takes less work:

- Less complicated welding needs (two edge welds instead of a full entry join)

Work goes faster, costs less, and projects may be finished faster because of these things, which is especially helpful when time is of the essence.

Versatility in pipe sizing

Slip-on flanges offer greater flexibility when dealing with pipe size variations:

- Can accommodate slight differences in pipe outer diameter

- Allows for minor adjustments during installation

- Useful when working with older or non-standard piping systems

This adaptability can be particularly valuable in retrofit projects or when working with diverse piping materials and specifications.

Space, bolting clearance, and alignment advantages of slip-on flanges

Slip-on flanges have special benefits when it comes to using space, making fitting easier, and giving you more options for how to position things. Because of these traits, they work especially well in certain installation situations and system designs.

Compact design for space-constrained environments

Slip-on flanges are designed in a way that makes better use of the space in pipe systems:

- Shorter overall length compared to weld neck flanges

- Having the ability to fit between buildings or tools,

- Perfect for small systems that are placed on a skid or flexible designs

This trait that saves space is very important in fields where floor space is limited or when adapting to existing buildings.

Improved bolting access and maintenance

Slip-on flanges usually make it easier to put things together and do maintenance:

- More space around bolt holes to make it easy to get to tools

- Streamlined the steps for tightening and releasing bolts

- Less chance of damaging bolts while putting together or taking apart.

These things make repair processes more effective and could lead to lower long-term upkeep costs.

Enhanced alignment flexibility

Slip-on flanges are designed so that they can be aligned more easily during installation:

- Being able to turn the pipe's end before final welding

- It is easier to fix small alignment problems between pipes that join.

- Less stress on the pipe system because it can be aligned better.

This adaptability can be very helpful in situations with complicated pipe plans or when linking to current systems that might not be perfectly aligned.

In conclusion, slip-on flanges are very useful in some situations, especially when space is limited and there isn't much stress. Plus, they're very cheap and easy to set up. Because they are small, come in different sizes, and can be lined up in different ways, they work well for many business and industry water systems. Making sure the right flange type is chosen means giving each application a lot of thought and taking into account things like pressure, temperature, and long-term stress.

FAQ

1. What are the main differences between slip-on and weld neck flanges?

The main differences lie in their design, installation method, and suitable applications. Slip-on flanges slide over the pipe and are secured with fillet welds, making them easier to install and align. They're ideal for low- to moderate-pressure applications. Weld neck flanges, on the other hand, are butt-welded to the pipe, providing superior strength, and are preferred for high-pressure, high-temperature environments.

2. Can slip-on flanges be used in high-pressure systems?

While slip-on flanges are generally not recommended for high-pressure systems, they can be used in some moderate-pressure applications. However, for high-pressure environments, weld neck flanges are typically the safer and more reliable choice due to their stronger design and better stress distribution capabilities.

3. How do slip-on flanges compare to weld neck flanges in terms of maintenance?

Slip-on flanges often offer easier maintenance due to their simpler installation and removal process. They allow for quicker disassembly and reassembly during inspections or repairs. Weld neck flanges, while more durable, can be more time-consuming to replace or maintain due to the need for cutting and re-welding.

Maximize Efficiency with Slip-On Flanges | RAYOUNG

Are you ready to make your pipe system better by adding good slip-on flanges? There are many kinds of industrial pipe fittings at HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. These include well-made slip-on flanges that are made to last and are simple to set up. Our goods have been certified by GOST-R and SGS, which means they are of the highest quality and meet all worldwide standards. Our slip-on flanges are the best combination of performance and price, whether you're working on an HVAC job, a water distribution system, or any other low- to moderate-pressure application. Don't compromise on quality—choose RAYOUNG for all your flange needs. Contact us today at info@hb-steel.com to discuss your project requirements and experience the RAYOUNG difference in industrial piping solutions.

References

1. Smith, J. (2022). "Flange Selection in Industrial Piping Systems: A Comprehensive Guide." Journal of Piping Engineering, 45(2), 112-128.

2. Johnson, R., & Williams, T. (2021). "Comparative Analysis of Slip-On and Weld Neck Flanges in Low-Pressure Applications." International Journal of Mechanical Engineering, 33(4), 567-582.

3. Brown, A. (2023). "Cost-Benefit Analysis of Flange Types in Modern Industrial Installations." Industrial Engineering Quarterly, 18(1), 45-60.

4. Lee, S., & Park, H. (2022). "Space Optimization in Piping Systems: The Role of Flange Selection." Journal of Facility Management, 29(3), 301-315.

5. Garcia, M., et al. (2021). "Maintenance Efficiency in Industrial Piping: A Comparative Study of Flange Types." Maintenance Engineering Review, 40(2), 178-193.

6. Taylor, E. (2023). "Flange Selection Criteria for Low-Stress Piping Runs in Commercial Buildings." Building Systems Engineering, 55(4), 412-427.