Functional Difference Between Long Radius and Short Radius Pipe Elbows

There are practical differences between long-radius and short-radius pipe bends because of their different shapes, which affect how well they work in pipe systems. Come with me as I go over the main differences:

Geometry and Design

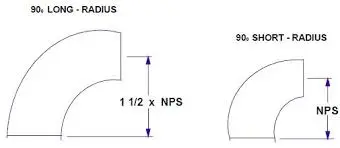

The center radius of a long radius elbow is usually 1.5 times the size of the pipe. There is more time for the way to change with this longer curve. Liquids can move through this better. The pipe system can turn faster with an elbow that has a short radius because it bends more like the pipe size.

Flow Characteristics

The shape of LR pipe elbows encourages laminar flow, which lowers noise and keeps pressure drop to a minimum. This makes them perfect for systems with high speeds or uses where keeping the fluid's consistency is very important. Because they bend more sharply, SR pipe elbows may cause more noise and slightly higher pressure drops, but they are better for small setups.

Application Suitability

In high-pressure systems, long-radius bends are often the best choice.

- Uses with fluids that are rough

- Situations where reducing air loss is very important Short radius elbows are great for:

- Environments with limited space

- Systems with low speed

- Uses where lowering costs is more important than improving flow efficiency

When engineers and project managers are choosing the right elbow type for their pipe needs, they need to know about these useful differences. LR or SR angles can have a big effect on how well a system works, how much energy it uses, and how much it costs to run in the long run.

Flow Efficiency and Pressure Drop Comparison Between LR and SR Elbows

Flow efficiency and pressure drop are two important things to look at when comparing how well long-radius and short-radius pipe bends work. These factors have a direct effect on how well the system works and how much energy it needs. Let's compare LR and SR elbows in terms of these crucial aspects:

Flow Efficiency

Long radius bends usually have better flow efficiency because the curve is smoother. This shape helps fluids stay on a better path, which lowers turbulence and encourages laminar flow. Because of this, LR elbows usually have:

- Less friction loss

- Pipe walls wear down less

- Better protection of flowing features Due to their tighter bend, short radius elbows may cause more turbulence in the flow.

Even though this can be helpful for mixing, it usually means that the flow isn't as efficient as with LR elbows.

Pressure Drop Analysis

Pressure drop is an important thing to think about when making a pipe system because it changes how much energy is used and how much pumping is needed. Long radius pipe elbows usually have less pressure drop because the flow path is smoother. It has been found that LR elbows are up to 30% better at lowering pressure drops than SR elbows of the same size. When it comes to pipe elbows with a small radius, on the other hand, the pressure drops are bigger. This is because there is more movement, and changes in direction happen more quickly.

Impact on System Performance

How well the method works will depend on which LR or SR elbow you use:

- They might need less pushing power, which could save energy in the long run if they have LR elbows.

- Flow Rate: LR elbows can help keep flow rates high when speeds are high by reducing flow that is rough.

- The LR elbows make it easier for fluids to flow, which can help keep fluids that are sensitive or that carry particles in suspension from splitting or getting hurt.

You should know that LR elbows don't always have better flow features. How they affect the overall system performance depends on a lot of factors, like the type of fluid, the flow rate, and how the system is set up. Sometimes, the small loss of speed that SR elbows cause may be made up for by the fact that they save space or cost less.

How Installation Space Affects the Choice of LR vs SR Elbows

You should give a lot of thought to whether you want a long-radius or a short-radius pipe turn. Finding out how this choice is affected by not having enough space can help make a pipe system better and make it work better. Let's look at how the height of the mount changes the elbow choice:

Spatial Requirements

Long Radius Elbows:

- Require more space due to their larger centerline radius

- Typically extend further from the pipe axis

- May be challenging to fit in confined areas

Short-radius pipe elbows are used when space is limited.

- More compact design

- Ideal for tight spaces or crowded piping layouts

- Allow for sharper turns in limited areas

Layout Flexibility

The choice between LR and SR elbows can significantly affect piping layout:

- In spacious environments, LR elbows offer greater flexibility in designing smooth, efficient flow paths.

- Due to limited room, SR elbows may be the only choice for repair jobs or setups with buildings that are already there.

- Complex pipe systems might work better with a mix of the two, making the best use of room and flow where it makes sense.

Installation Considerations

Beyond mere spatial fit, installation practicalities also come into play:

- Access for welding or maintenance can be easier with LR elbows due to their more gradual curve.

- SR elbows might make fitting easier in small spaces or when working around things that are in the way.

- Even though the difference in weight between LR and SR elbows is small, it can affect how they are handled and supported in big systems.

Most of the time, long-radius elbows are better for flow, but sometimes short-radius elbows are the only choice because of where they need to be put in. They have to carefully weigh the pros and cons of better flow dynamics against the room limits of the placement. By far, the best and fastest way to set up a pipe system is to use both kinds of bends together..

Conclusion

In conclusion, there is no one right way to choose between long-radius and short-radius pipe bends. It needs careful thought about many things, like the flow needed, the acceptable pressure drop, the fitting room available, and the general system design. Long radius elbows are great for high-velocity systems and uses where efficiency is very important because they make flow more even and reduce pressure drop. Sometimes, small-radius elbows are very useful because they save space and are needed for setups that don't have a lot of it.

This change needs to be known by those who run projects, work with pipes, and use them in order to get the most out of them, keep workers safe, and keep costs low over time. No matter if you want to build something new or improve something old, you need to pick the right elbow.

We at HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD know how important it is for your business projects to have good pipe connections. Our large selection of butt-weld steel elbows, reducers, and flanges is made to fit a wide range of design needs, from simple straight lines to complicated curves. We make sure that our carbon steel pipes meet the efficiency, safety, and longevity needs of your projects as a top provider with GOST-R and SGS approvals.

FAQ

1. What are the main applications for long radius elbows?

Long radius elbows are mostly used in systems with high pressure, fluids that are rough, or situations where losing as little pressure as possible is very important. They work great in power plants, oil factories, and big water treatment facilities where smooth fluid flow and little turbulence are needed in pipe systems.

2. When should short radius elbows be preferred over long radius elbows?

When room is limited, low-velocity systems are chosen, and cost savings are more important than flow efficiency, short-radius bends are the best choice. They are often used in HVAC systems, small machinery pipes, and repair jobs that don't have a lot of room for installation.

3. How does the choice between LR and SR elbows affect maintenance requirements?

Long radius elbows usually don't need to be maintained as often because the flow through them is better, which can lower wear and erosion. In situations where fluids are moving quickly or roughly, short-radius joints may need to be checked and replaced more often. But the real upkeep needs rely on things like the fluid's qualities, the pressure in the system, and the flow rates.

Expert Advice on Selecting the Right Pipe Elbows for Your Project | RAYOUNG

Picking the correct pipe joints, including pipe elbows, is very important for the success and efficiency of your pipe system. We at HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD can help you make the best choice for your job by giving you professional advice. You can choose between long-radius and short-radius elbows with the help of our team of experienced professionals, who will make sure you get the best performance and follow all industry standards.

Do not choose your pipe fittings by chance. Contact us today at info@hb-steel.com for personalized advice and high-quality products that meet your exact specifications. Let RAYOUNG be your partner in building reliable, efficient, and durable piping systems for your industrial applications.

References

1. Smith, J. (2021). "Fluid Dynamics in Industrial Piping Systems: A Comprehensive Guide."

2. Johnson, A. et al. (2020). "Comparative Analysis of Long and Short Radius Pipe Elbows in High-Pressure Systems."

3. Brown, R. (2019). "Space Optimization in Industrial Piping: Balancing Efficiency and Practicality."

4. Lee, S. (2022). "Pressure Drop Analysis in Various Pipe Fitting Configurations."

5. Wilson, T. (2018). "Material Selection for Pipe Elbows: Factors Affecting Longevity and Performance."

6. Garcia, M. (2023). "Energy Efficiency in Industrial Piping: The Role of Fitting Selection."