What Are the Different Types of Steel Pipe Fittings Used in Industrial Piping Systems?

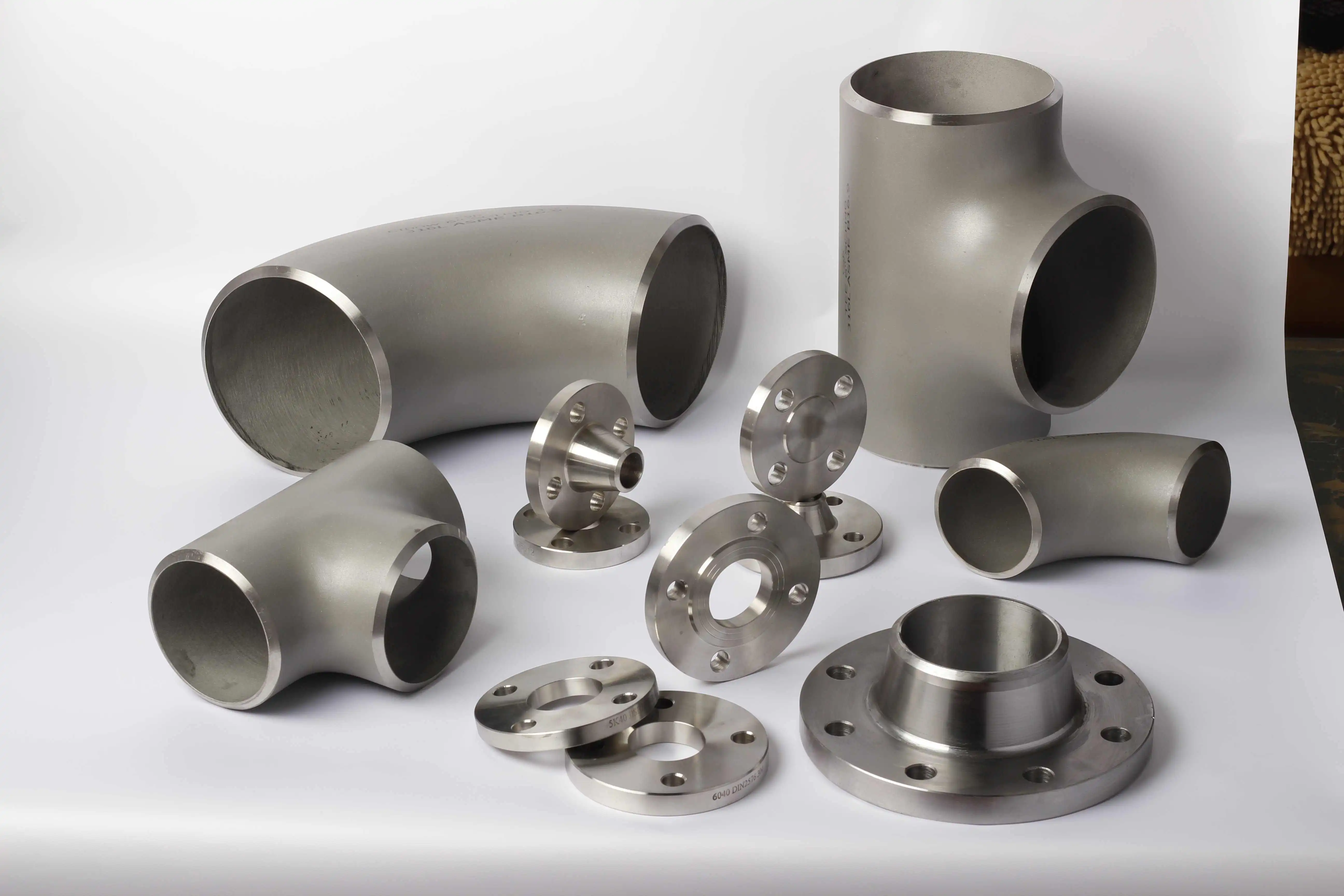

Mechanical channeling systems depend heightening on distinctive sorts of Steel Pipe Fittings to ensure fitting stream control, course changes, and secure affiliations all through complex frameworks. These essential components serve as the spine of manufacturing workplaces, chemical plants, oil refineries, and control time systems around the world. Steel Pipe Fittings encompass a arranged amplify of things checking elbows, tees, reducers, ribs, and unions, each laid out for specific applications and working conditions. Understanding the specific characteristics, applications, and execution capabilities of different Steel Pipe Fittings sorts is significant for engineers, acquirement masters, and back specialists included in mechanical channeling system arrange and operation.

Classification of Steel Pipe Fittings by Function and Design

Directional Change Fittings

Steel Pipe Fittings arranged for directional changes talk to the most commonly utilized components in mechanical channeling systems, with elbows serving as the fundamental course of action for coordinating pipelines around obstructions and through confined spaces. Standard 90-degree elbows redirect stream at right focuses though keeping up water fueled efficiency, with long span varieties promoting diminished weight drop compared to brief clear choices. These Steel Pipe Fittings are made in distinctive divider thicknesses to oblige different weight evaluations, with arrange 40, 80, and 160 being standard options for most mechanical applications. The inward stream characteristics of directional Steel Pipe Fittings through and through influence by and huge system execution, as dishonorable assurance can make turbulence, weight incidents, and deterioration that compromise long-term faithful quality. 45-degree elbows grant gentler heading changes where space awards, publicizing predominant water fueled execution for applications requiring unimportant weight drop over fittings.

Branch Connection Fittings

Tee fittings talk to the vital course of action for making division affiliations in Steel Pipe Fittings systems, engaging single channel streams to portion into diverse outlet streams or combining various inlet streams into single outlets. Break indeed with tees keep up unfaltering separate over over all three affiliations, though diminishing tees solidify unmistakable sizes to oblige changing stream necessities all through the system. The stream transport characteristics of tee Steel Pipe Fittings depend heightening on inlet speed, office point, and separate over extents, with fitting water fueled examination crucial for fulfilling needed execution. Wye fittings offer an elective division affiliation arrange with calculated outlets that reduce turbulence and weight incident compared to standard tees, particularly profitable in applications with tall stream speeds or unbending weight drop necessities. Cross fittings engage four-way affiliations but are less common due to essential obstructions and complex thrust plans that make underneath interior weight loading.

Size Transition Fittings

Reducer fittings enable smooth moves between particular pipe separations over though keeping up true blue stream characteristics and minimizing weight mishaps all through Steel Pipe Fittings systems. Concentric reducers provide symmetrical breadth diminishment with centered stream ways, making them idealize for level foundations where uniform speed spread is required. Unusual reducers keep up level surfaces on one side to expect talk about take course of action in level lines or energize drainage in inclined foundations, talking to fundamental Steel Pipe Fittings for applications counting two-phase streams or systems requiring add up to squander capability. The move point of reducer Steel Pipe Fittings impacts stream characteristics, with nonstop diminishes minimizing turbulence and weight drop though douse moves may make parcel zones that diminish efficiency. True blue measuring and choice of reducer Steel Pipe Fittings requires cautious examination of upstream and downstream conditions to ensure perfect weight driven execution all through the working range.

Steel Pipe Fittings Material Specifications and Standards

Carbon Steel Specifications

Carbon steel talks to the most broadly utilized texture for Steel Pipe Fittings in mechanical applications due to its astonishing strength-to-cost extent and wide compatibility with diverse handle fluids. ASTM A234 Survey WPB serves as the standard assurance for coordinate temperature applications, giving tried and true execution up to 400°C with palatable mechanical properties for most mechanical channeling systems. These Steel Pipe Fittings appear astounding weldability and machinability, enabling profitable foundation and modification strategies in the midst of advancement and upkeep works out. Moo temperature carbon steel grades like A234 WPL6 grow advantage capabilities to cryogenic applications though keeping up the money related central focuses of carbon steel improvement. The microstructural characteristics of carbon steel Steel Pipe Fittings can be changed through warm treatment shapes to fulfill specific mechanical properties required for asking applications.

Stainless Steel Grades

Stainless steel Steel Pipe Fittings offer predominant disintegration resistance and high-temperature execution compared to carbon steel alternatives, making them principal for chemical dealing with, food era, and pharmaceutical applications. Audit 304 stainless steel gives astonishing common disintegration resistance and make characteristics, talking to the most common choice for coordinate disintegration circumstances and temperatures up to 800°C. Survey 316 joins molybdenum increments that basically advance resistance to chloride-induced disintegration, making these Steel Pipe Fittings idealize for marine circumstances and chemical shapes counting halogenated compounds. Duplex stainless steels combine austenitic and ferritic microstructures to fulfill overhauled quality and thrust disintegration part resistance compared to schedule austenitic grades. Super austenitic stainless steel Steel Pipe Fittings donate exceptional execution in exceedingly commanding chemical circumstances where standard grades illustrate inadequate.

Alloy Steel Properties

Alloy steel Steel Pipe Fittings connect specific alloying components to fulfill overhauled mechanical properties, temperature resistance, and specialized execution characteristics required for asking mechanical applications. Chrome-molybdenum combinations like A234 WP11 and WP22 donate awesome high-temperature quality and slither resistance, making them essential for control period and petrochemical applications working over 450°C. These Steel Pipe Fittings keep up assistant judgment underneath kept up stacking at lifted temperatures where carbon steel would experience quick debilitating. Nickel-based amalgam increments advance low-temperature solidness and influence resistance, engaging Steel Pipe Fittings applications in cryogenic advantage where carbon steel gets to be sensitive and flawed. The warm treatment necessities for combination steel Steel Pipe Fittings are more complex than carbon steel, requiring correct temperature control and cooling rates to fulfill needed microstructural characteristics and mechanical properties.

Manufacturing Processes and Quality Standards

Fabrication Methods

Seamless manufacturing talks to the premium era technique for Steel Pipe Fittings, counting hot forming shapes that make nonstop grain structures without longitudinal welds that may compromise weight rating or disintegration resistance. This manufacturing approach produces Steel Pipe Fittings with predominant mechanical properties and weight control capabilities, particularly basic for high-pressure applications in oil and gas, control period, and chemical dealing with businesses. The reliable get ready arranges of potential slight centers related with welded improvement while giving uniform divider thickness transport all through complex fitting geometries. Designed Steel Pipe Fittings involvement additional mechanical working that refines grain structure and moves forward mechanical properties compared to cast choices, coming approximately in overhauled shortcoming resistance and influence sturdiness. The creating get ready enables correct dimensional control and surface wrap up quality that meets demanding mechanical necessities for essential applications.

Welded Construction Techniques

Welded Steel Pipe Fittings utilize progressed joining procedures to make dependable associations whereas keeping up cost-effectiveness for less basic applications. Electric resistance welding produces longitudinal creases with great metallurgical holding characteristics, making Steel Pipe Fittings appropriate for direct weight applications where consistent development may not be financially defended. Submerged circular segment welding empowers manufacture of expansive breadth Steel Pipe Fittings with steady weld quality and negligible heat-affected zone characteristics that may compromise fabric properties. The welding handle parameters must be carefully controlled to accomplish legitimate entrance, combination, and mechanical properties all through the joint zone. Post-weld warm treatment regularly gets to be vital for combination steel Steel Pipe Fittings to reestablish ideal microstructure and soothe leftover stresses that might influence long-term performance.

Quality Control and Testing

Non-destructive testing talks to a essential point of Steel Pipe Fittings manufacturing, ensuring fundamental judgment and dimensional precision a few time as of late shipment to conclusion clients. Radiographic examination reveals interior deserts, porosity, and contemplations that might compromise weight control or mechanical execution of Steel Pipe Fittings in the midst of advantage. Ultrasonic testing gives nitty coarse divider thickness estimations and recognizes laminations or other planar surrenders that may not be unmistakable through radiographic techniques. Dimensional survey ensures Steel Pipe Fittings alter to shown resistances for true blue fit-up with mating components and compliance with relevant channeling codes. Hydrostatic testing affirms weight control capabilities underneath controlled conditions that reproduce or outperform honest to goodness advantage prerequisites for Steel Pipe Fittings applications.

Conclusion

Steel Pipe Fittings incorporate varying sorts checking directional change components, division affiliations, and gauge moves, each serving specific capacities interior mechanical channeling systems. Texture subtle elements expand from carbon steel to advanced combinations, with manufacturing shapes moving from steady to welded improvement based on application necessities. Quality measures ensure strong execution through comprehensive testing and audit traditions that affirm fundamental perception and dimensional exactness.

Premium Steel Pipe Fittings Manufacturers and Suppliers | JS FITTINGS

JS FITTINGS stands as a genuine maker based in Yanshan Territory, Cangzhou City, Hebei Zone, China, with a long time of industry experience building up us as a tried and true source for premium Steel Pipe Fittings and butt-weld pipe components. Our exceedingly skilled specialists bring ability and excitement to each wander, ensuring transcendent quality things checking buttweld elbows, butt weld tees, pipe reducers, and steel pipe ribs that meet around the world benchmarks. With Steel Pipe Fittings sent out to over 50 countries tallying the UAE, Canada, Mexico, South America, Europe, Center East, and Asia Pacific, we get it diverse mechanical prerequisites and grant custom courses of action custom fitted to adjust points of interest. Our state-of-the-art workplaces and show day era lines ensure fast movement and correct creating, supported by ISO9001:2015, CE, GOST-R, and PED certifications that guarantee quality and immovable quality. Whether you require standard or specialized Steel Pipe Fittings for your mechanical channeling system, our commitment to progression and brilliance passes on comprehensive courses of action with demonstrate client advantage and fulfillment guarantees. Contact us these days at admin@jsfittings.com to look at your Steel Pipe Fittings necessities and inclusion the JS FITTINGS differentiate in quality, faithful quality, and client reinforce.

References

1. Smith, P.R. (2020). Industrial Piping Systems: Design and Component Selection. McGraw-Hill Engineering Publications.

2. Johnson, M.A. (2019). Steel Pipe Fittings in Process Industries: Materials and Applications. Elsevier Technical Press.

3. Williams, D.K. (2021). Manufacturing Standards for Industrial Pipe Fittings. ASME Press Professional Publications.

4. Anderson, L.C. (2018). Corrosion Resistance of Steel Piping Components. CRC Press Engineering Series.

5. Thompson, R.J. (2020). Quality Control in Pipe Fitting Manufacturing. John Wiley & Sons Industrial Division.

6. Martinez, S.E. (2019). Advanced Materials for High-Performance Piping Systems. Butterworth-Heinemann Technical Books.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise