Sand Casting vs Investment Casting: Which is Best for Pipe Flanges

When looking for the best way to make steel pipe flanges, you need to carefully compare the sand casting and investment casting methods. Each has its own benefits when it comes to accuracy in measurements, surface finish, cost of production, and use of different materials. Using disposable sand molds, sand casting is the usual way to make flanges. It gives you great material properties and is cost-effective for medium to large production volumes. Investment casting, also called lost-wax casting, uses clay shell molds to make parts with very precise dimensions and surfaces. This makes it perfect for parts with complicated shapes and where accuracy is important. Engineers can choose the best ways to make things that improve performance, stability, and the overall cost of ownership by knowing what each process can do technically and how it will affect the economy.

Sand Casting Process for Steel Pipe Flanges

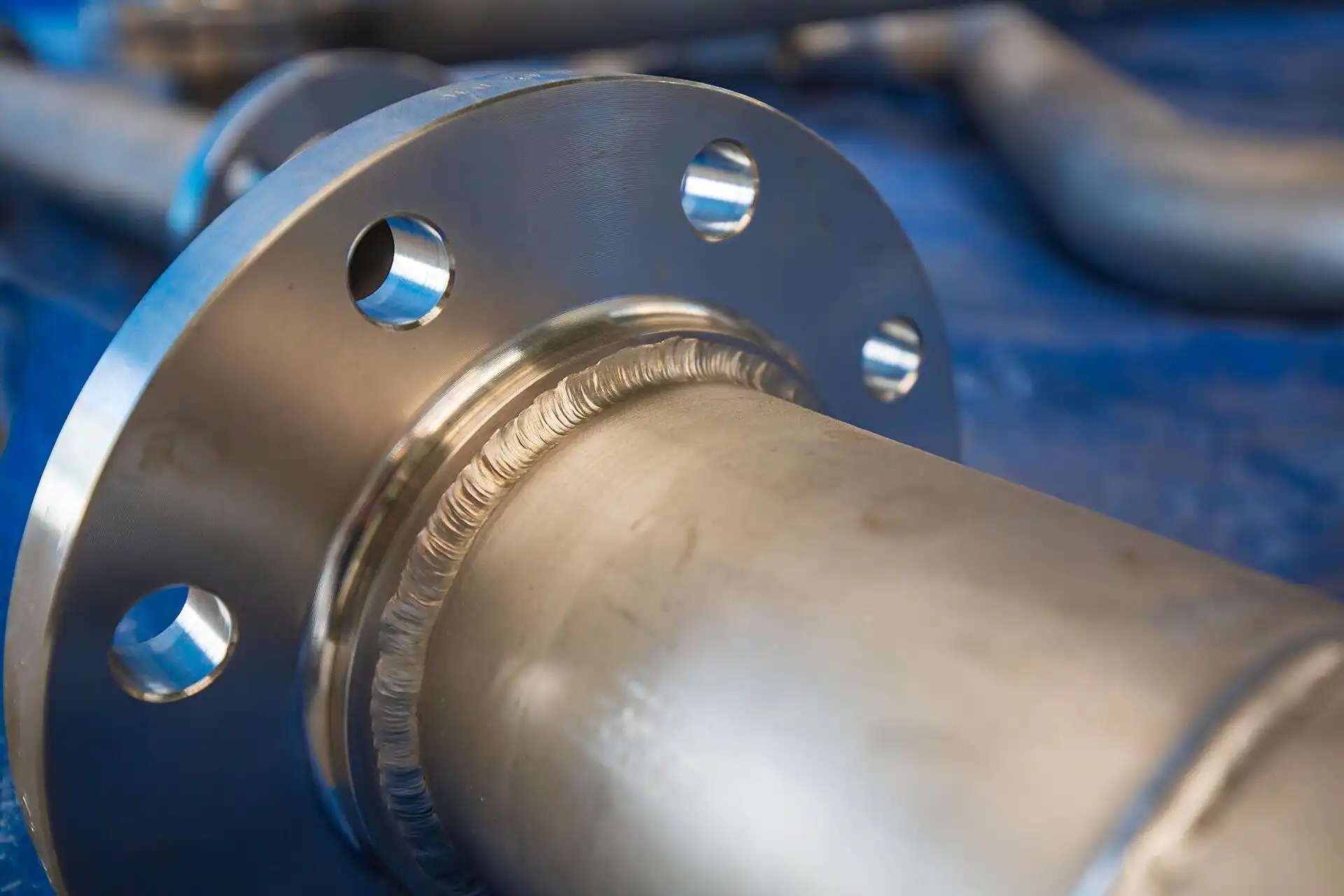

Sand casting begins with pattern creation that replicates the final flange geometry with allowances for metal shrinkage and machining. The pattern is surrounded by molding sand mixed with bonding agents, creating a negative cavity matching the desired configuration. Molten steel heated above 2800°F is poured into the mold cavity through a gating system designed to control fill rate and ensure complete filling without defects. After solidification, the sand mold is broken away, and the rough casting undergoes cleaning operations to remove adhered sand and prepare surfaces for machining.

Steel pipe flanges produced through sand casting exhibit excellent mechanical properties from relatively slow cooling rates that promote uniform grain structure. The process accommodates a wide range of flange sizes from small fittings through massive industrial flanges weighing several tons, with virtually no upper size limitation. Modern facilities employ automated molding lines and computer-controlled pouring systems that ensure consistent quality while maintaining fundamental cost advantages.

Sand cast steel pipe flanges typically meet specifications including ASTM A216 Grade WCB, with tensile strengths of 70,000 to 95,000 psi and yield strengths of 36,000 psi minimum. Surface finish ranges from 250 to 500 microinches roughness average, requiring machining of critical sealing surfaces and bolt holes. Dimensional accuracy generally falls within tolerances of plus or minus 1/16 inch for smaller features. Modern foundries employ ultrasonic testing, radiographic examination, or magnetic particle inspection to detect porosity, shrinkage cavities, or inclusions that could compromise integrity.

Sand casting offers compelling economic advantages, particularly for medium-to-large production volumes where tooling costs are amortized across multiple units. Pattern costs remain modest compared to investment casting tooling, with simple wooden patterns costing hundreds of dollars versus thousands for high-volume metal patterns. Material utilization typically ranges from 50% to 70% depending on component geometry. Lead times typically span several weeks from order through delivery. The flexibility of sand casting accommodates design modifications relatively easily through pattern changes, making it economically viable even for modest production quantities.

Investment Casting for Precision Applications

Investment casting employs wax pattern injection into precision aluminum dies that capture intricate details impossible to achieve through sand casting. Multiple wax patterns are assembled onto a central sprue, enabling simultaneous casting of numerous flanges in a single pour. The wax assembly receives multiple ceramic slurry coatings, building a robust shell mold capable of withstanding molten steel temperatures. After curing, the wax patterns are melted out, creating precise cavities. The ceramic shells are preheated before molten steel is poured, promoting complete filling of thin sections and fine details.

Investment cast steel pipe flanges exhibit exceptional dimensional accuracy with tolerances typically held to plus or minus 0.005 to 0.010 inches, dramatically reducing or eliminating subsequent machining requirements. Surface finish averages 63 to 125 microinches roughness, approaching machined quality directly from casting and often acceptable for non-sealing surfaces without additional finishing. The process accommodates complex geometries, including undercuts, internal passages, and intricate surface features impossible to produce through other casting methods.

Investment cast flanges deliver superior quality characteristics with tighter dimensional control, improved surface integrity, and enhanced metallurgical properties. Near-net-shape capability minimizes machining requirements, reducing production time and preserving material. Dimensional consistency between castings enables interchangeability without individual fitting. Surface quality exhibits minimal defects, including reduced porosity and fewer inclusions, enhancing corrosion resistance. Controlled solidification promotes fine-grain structure and uniform mechanical properties throughout the component. Investment casting particularly excels for smaller diameter steel pipe flanges where economic premiums remain manageable and quality advantages justify the investment.

Investment casting commands premium pricing due to higher tooling costs, expensive ceramic shell materials, longer production cycles, and increased labor content. Pattern tooling typically costs several thousand to tens of thousands of dollars, representing significant upfront investment requiring high production volumes for competitive unit costs. Applications specifying tight tolerances, superior surface finish, or complex geometries may find investment casting economically attractive even at modest volumes due to reduced secondary processing costs. Small diameter flanges under six inches often prove economically viable, while larger flanges increasingly favor sand casting. Lead times typically exceed sand casting due to pattern assembly and shell building processes.

Comparative Analysis and Selection

Dimensional tolerances achievable through investment casting of steel pipe flanges typically range from 0.005 to 0.010 inches compared to 0.030 to 0.060 inches for sand castings. Surface finish on investment castings averages 63 to 125 microinches compared to 250 to 500 microinches for sand castings. Mechanical properties of properly produced castings from both processes meet applicable material specifications. Design flexibility favors investment casting for complex geometries, while sand casting accommodates larger components.

Selecting between processes for steel pipe flanges for sale requires systematic economic analysis, accounting for tooling costs, piece price, production volume, machining requirements, and total lifecycle costs. Sand casting patterns cost hundreds to thousands of dollars compared to investment casting tooling, ranging from several thousand to tens of thousands. Investment castings command premiums of 50% to 300% over sand castings before considering machining cost differences. Production volume dramatically influences process selection, with sand casting favored for larger quantities.

Large diameter flanges exceeding twelve inches typically favor sand casting due to prohibitive investment casting costs. Small precision flanges under six inches with tight tolerance requirements often justify investment casting. Standard catalog flanges produced in substantial volumes generally employ sand casting. Specialty flanges for unique applications may specify investment casting despite cost premiums when performance requirements justify the precision approach.

Conclusion

Both sand casting and investment casting produce high-quality steel pipe flanges suitable for demanding industrial applications, with process selection dependent on size, complexity, tolerance requirements, production volume, and economic considerations. Sand casting excels for larger flanges and high-volume production, while investment casting delivers superior precision for smaller components. HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. leverages advanced casting technologies and ISO 9001:2015 quality systems to manufacture steel pipe flanges that meet stringent performance standards across diverse applications, offering comprehensive solutions from standard catalog items to custom configurations backed by expert engineering support and rigorous quality assurance. For more information, please contact us at info@hb-steel.com.

References

1. Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. 3rd ed., Butterworth-Heinemann, 2020.

2. Beeley, P. R. Foundry Technology. 2nd ed., Butterworth-Heinemann, 2001.

3. American Foundry Society (AFS). Metalcasting Process Comparison Chart. AFS Publications, 2019.

4. Davis, J. R. (ed.). ASM Specialty Handbook: Cast Irons. ASM International, 1996.

5. Totten, G. E., and MacKenzie, D. S. (eds.). Handbook of Aluminum: Vol. 2, Alloy Production and Materials Manufacturing. CRC Press, 2003.

6. Groover, M. P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. 8th ed., Wiley, 2023.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise