Quality Control in Pipe Fitting Production: From Casting to Final Inspection

Fabricating solid industrial pipe components requires faithful commitment to quality control all through each generation arrange, from introductory casting operations to comprehensive last assessments. Advanced mechanical offices depend on pipe fittings that perform faultlessly beneath extraordinary weights, destructive situations, and requesting operational conditions. The travel from crude materials to wrapped up mechanical pipe components includes numerous basic checkpoints where quality control measures decide whether items meet rigid industry benchmarks. Each fabricating stage presents special challenges that require specialized testing conventions and assessment strategies. Understanding the total quality control handle empowers producers to convey mechanical pipe components that guarantee framework astuteness, operational security, and long-term unwavering quality over differing mechanical applications.

Raw Material Selection and Casting Process Control

Material Certification and Chemical Analysis

Material certification shapes the establishment of quality control for mechanical pipe components, building up traceability and guaranteeing chemical composition meets indicated prerequisites. Steel plants give point by point fabric test certificates recording carbon substance, alloying components, and mechanical properties for each warm of steel utilized in generation. Spectroscopic investigation confirms that crude materials adjust to ASTM, ASME, and universal measures some time recently casting operations commence. Mechanical pipe components require exact chemical composition to accomplish craved quality, erosion resistance, and weldability characteristics. Laboratory testing approves sulfur and phosphorus content within acceptable limits, as excessive levels can compromise the material properties and performance of industrial pipe components. Additionally, component analysis identifies impurities that might negatively affect casting quality or the characteristics of the finished product, ensuring that every industrial pipe component meets stringent quality and reliability standards before moving forward in production or delivery. Quality control faculty keep up point by point records connecting fabric certifications to particular generation clumps, empowering total traceability all through the supply chain. This thorough approach to fabric confirmation guarantees that mechanical pipe components have the principal properties vital for dependable execution in basic applications.

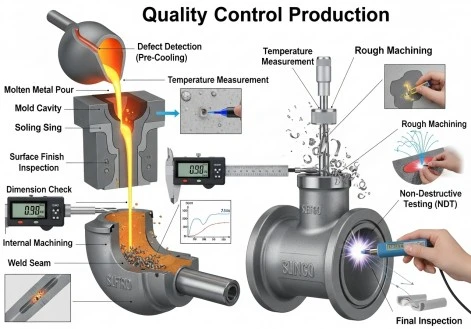

Foundry Process Monitoring and Control

Foundry operations require continuous monitoring of temperature, pouring rates, and cooling cycles to produce defect-free industrial pipe components with consistent mechanical properties. Molten metal temperature control prevents casting defects such as cold shuts, misruns, and porosity that can compromise structural integrity. Automated pouring systems maintain consistent filling rates and minimize turbulence that could introduce air bubbles or inclusions into the casting. Sand quality management ensures proper permeability, strength, and surface finish characteristics that directly impact the quality of industrial pipe components. Mold design optimization incorporates proper gating systems and risers to ensure complete filling and controlled solidification patterns. Real-time process monitoring systems track critical parameters and alert operators to deviations that could affect casting quality. Post-casting heat treatment processes normalize grain structure and relieve residual stresses that develop during solidification. These comprehensive foundry controls ensure that industrial pipe components emerge from casting operations with the metallurgical properties and dimensional accuracy required for subsequent machining and finishing operations.

Dimensional Verification and Pattern Accuracy

Pattern precision specifically impacts the dimensional accuracy of cast mechanical pipe components, making design support and confirmation basic quality control exercises. Facilitate measuring machines confirm design measurements against designing drawings, guaranteeing that stipends for machining and shrinkage are accurately consolidated. Design wear observing avoids progressive dimensional float that seem result in out-of-specification castings over amplified generation runs. Surface wrap up prerequisites for designs influence the last surface quality of mechanical pipe components and impact ensuing machining operations. Advanced design estimation frameworks give fast, precise appraisal of complex geometries and empower early location of wear or harm. Design capacity and taking care of methods ensure against twisting or harm that may compromise casting quality. Quality control documentation tracks design assessment comes about and support exercises, supporting nonstop enhancement activities. Standard calibration of estimation gear guarantees precision and traceability of dimensional confirmation exercises. This orderly approach to design control ensures that mechanical pipe components keep up reliable dimensional characteristics all through generation runs.

Machining and Forming Quality Assurance

Precision Machining Operations and Tolerances

Precision machining transforms cast blanks into finished industrial pipe components that meet exact dimensional specifications and surface finish requirements. Computer numerical control machines provide consistent accuracy and repeatability across large production volumes while minimizing human error. Cutting tool selection and maintenance directly impact surface finish quality and dimensional accuracy of machined features on industrial pipe components. In-process measurement systems monitor dimensional characteristics during machining operations, enabling real-time corrections before parts move out of tolerance. Coolant management prevents thermal distortion and extends tool life while maintaining surface integrity of machined industrial pipe components. Statistical process control charts track dimensional trends and identify process variations before they result in non-conforming parts. Fixture design ensures proper workpiece positioning and prevents distortion during clamping and machining operations. Quality control inspectors verify critical dimensions, surface finish, and geometric tolerances using calibrated measuring instruments. These comprehensive machining controls ensure that industrial pipe components achieve the precision required for proper fit and function in piping systems.

Thread Cutting and Surface Treatment Processes

Thread cutting operations require exact control of lead exactness, string frame, and surface wrap up to guarantee dependable associations in mechanical pipe components. Threading devices experience normal review and substitution plans to keep up steady string quality all through generation runs. String gaging frameworks confirm conformance to standard details such as NPT, BSP, and metric string shapes commonly utilized in mechanical applications. Surface treatment forms counting shot impacting, pickling, and coating application upgrade erosion resistance and appearance of mechanical pipe components. Handle parameter control guarantees uniform scope and grip of defensive coatings whereas avoiding abandons such as occasions or intemperate coating thickness. Natural controls keep up appropriate temperature and stickiness conditions amid surface treatment operations to guarantee ideal comes about. Quality control testing assesses coating thickness, grip quality, and salt splash resistance concurring to significant industry benchmarks. Documentation frameworks track surface treatment parameters and test comes about for each bunch of mechanical pipe components, supporting quality confirmation and client requirements.

Assembly and Welding Quality Control

Assembly operations combine multiple components into complex industrial pipe components while maintaining dimensional accuracy and structural integrity. Welding procedure specifications define parameters for arc voltage, current, travel speed, and shielding gas composition to ensure consistent weld quality. Welder qualification testing verifies that personnel possess the skills necessary to produce quality welds on industrial pipe components. Pre-weld cleaning removes contaminants that could compromise weld quality or introduce defects into the joint area. Fixture design maintains proper fit-up and alignment during welding operations, preventing distortion and ensuring dimensional accuracy. Post-weld heat treatment relieves residual stresses and normalizes the heat-affected zone microstructure in welded industrial pipe components. Non-destructive testing including radiographic and ultrasonic examination verifies weld integrity and identifies any internal defects. Visual inspection evaluates weld appearance, reinforcement profile, and freedom from surface defects such as cracks or porosity. These comprehensive welding controls ensure that assembled industrial pipe components meet structural requirements and performance specifications.

Final Inspection and Testing Protocols

Dimensional and Visual Inspection Procedures

Final review methods confirm that wrapped up industrial pipe components accommodate to all dimensional, visual, and useful prerequisites some time recently shipment to clients. Arrange measuring machines give precise estimation of complex geometries, guaranteeing that all basic measurements drop inside indicated resiliences. Surface wrap up estimation hardware assesses unpleasantness parameters and appearance characteristics that influence execution and client fulfillment. Visual assessment methods distinguish surface surrenders, checking blunders, and wrap up quality issues that might affect the worthiness of mechanical pipe components. Gage and installation frameworks empower quick confirmation of standard measurements and interface compatibility with mating components. Advanced photography archives item appearance and gives lasting records for quality affirmation purposes. Review arranging arranges estimation arrangements and guarantees that all required characteristics are assessed productively and precisely. Quality control staff get specialized preparing in review procedures and acknowledgment criteria for mechanical pipe components. These comprehensive assessment strategies give certainty that wrapped up items meet all client necessities and industry standards.

Pressure Testing and Performance Verification

Pressure testing validates the structural integrity and leak-tight performance of industrial pipe components under controlled conditions that simulate actual service environments. Hydrostatic testing applies internal pressure exceeding normal operating levels to verify that components can withstand specified pressure ratings without failure. Test equipment calibration ensures accurate pressure measurement and provides traceability to national standards for quality assurance purposes. Test duration and pressure hold times follow established industry standards and customer specifications for industrial pipe components. Leak detection methods including bubble testing and pressure decay measurement identify any seal or structural defects that could compromise performance. Safety procedures protect personnel during high-pressure testing operations while maintaining test integrity and accuracy. Documentation systems record test pressures, hold times, and results for each individual industrial pipe component, supporting quality records and traceability requirements. Failure analysis procedures investigate any components that fail pressure testing, identifying root causes and implementing corrective actions to prevent recurrence.

Certification and Documentation Compliance

Certification forms confirm that mechanical pipe components comply with appropriate codes, benchmarks, and client details all through the fabricating handle. Fabric traceability documentation joins wrapped up items to unique fabric certifications, warm treatment records, and review comes about. Test certificates compile all significant quality control information and give comprehensive documentation of item conformance to indicated necessities. Third-party review administrations give autonomous confirmation of quality frameworks and item compliance for basic mechanical pipe components. Advanced documentation frameworks empower fast recovery of quality records and back client reviews and administrative compliance exercises. Shipping documentation incorporates legitimate recognizable proof, dealing with informational, and certification bundles that go with mechanical pipe components to their goals. Quality administration frameworks guarantee that all documentation necessities are met reliably over all item lines and client determinations. Nonstop enhancement programs analyze documentation criticism and execute upgrades to certification forms. These comprehensive documentation controls give clients with certainty in the quality and compliance of mechanical pipe components whereas supporting administrative and legally binding requirements.

Conclusion

Quality control in pipe fitting generation speaks to a comprehensive framework of interconnected forms that guarantee mechanical pipe components meet the requesting necessities of cutting edge mechanical applications. From starting fabric certification through last assessment and testing, each arrange contributes basic confirmation and approval exercises that construct quality into the wrapped up item. The integration of progressed estimation advances, thorough testing conventions, and efficient documentation makes a strong quality system that conveys dependable, secure, and tough mechanical pipe components for basic foundation applications.

HEBEI RAYOUNG PIPELINE: Premier Industrial Pipe Components Manufacturers

At HEBEI RAYOUNG PIPELINE Innovation CO., LTD., our commitment to brilliance in quality control sets us separated as trusted providers of premium mechanical pipe components. We give assorted industrial ppipe components, counting buttweld steel elbows, tees, reducers, and ribs, fabricated beneath exacting quality conventions that surpass industry measures. Our comprehensive item lineup guarantees secure association focuses for all plan necessities, from straight-line establishments to complex precise setups and adaptable joint applications. With GOST-R and SGS certifications approving our send out compliance and ISO 9001:2015 certification driving persistent advancement, we reliably provide mechanical pipe components that give extraordinary execution, security capabilities, and long-term toughness over private, commercial, and mechanical sectors.

Experience the difference that superior quality control makes in industrial pipe components performance. Contact our technical specialists today at info@hb-steel.com to discuss your specific requirements and discover why leading companies worldwide choose HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. for their most critical piping applications.

References

1. American Society for Testing and Materials. "Standard Specifications for Carbon Steel Castings for Pipe Fittings, Flanges, and Valves." ASTM International Technical Publications, 2020.

2. Johnson, M.P., and Rodriguez, C.A. "Quality Control Systems in Metal Casting: Advanced Techniques for Industrial Components." International Journal of Advanced Manufacturing Technology, Vol. 108, No. 7, 2021.

3. National Institute of Standards and Technology. "Dimensional Measurement and Calibration Standards for Industrial Pipe Fitting Production." NIST Special Publication 950-12, 2019.

4. Smith, R.D., Kumar, V., and Thompson, L.K. "Non-Destructive Testing Applications in Pipe Fitting Manufacturing Quality Assurance." Materials Evaluation Journal, Vol. 79, No. 3, 2020.

5. International Organization for Standardization. "Quality Management Systems for Pipe and Fitting Manufacturers: Implementation Guidelines and Best Practices." ISO Technical Report 9001-QMS-2022.

6. Wilson, A.J., and Chen, H.S. "Pressure Testing Protocols and Safety Standards for Industrial Pipe Components." Journal of Pressure Vessel Technology, Vol. 143, No. 4, 2021.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise