Pipe Elbow Degrees Guide: 45° vs 90° vs 180° Usage Explained

Understanding the appropriate application of diverse pipe elbows points is significant for planning productive channeling frameworks that adjust stream flow, space limitations, and establishment necessities. The three essential elbow setups - 45°, 90°, and 180° - each serve particular capacities in mechanical and commercial channeling applications, advertising special focal points for diverse operational scenarios. Engineers must consider variables counting weight drop, stream turbulence, support get to, and basic impediments when selecting suitable elbow points for their frameworks. This comprehensive direct investigates the specialized details, execution characteristics, and ideal utilization scenarios for each elbow sort, empowering educated decision-making that guarantees long-term framework unwavering quality and operational productivity over different mechanical applications.

45-Degree Pipe Elbow Applications

Flow Optimization Benefits

When it comes to flow, 45-degree pipe elbows work better than sharper angles because they reduce pressure drops and turbulence in systems that move fluids. The slow change in direction keeps the flow patterns smoother, which makes these elbows perfect for situations where saving energy and money on pumping costs are important. High-quality butt-weld pipe fittings with exact size specs make sure that flow changes go smoothly without leaving any dead spots or recirculation areas that could hurt the system's performance. The extended radius form of 45-degree elbows spreads stress more evenly across the part, making it less likely to wear out in systems that go through cycles of changing pressure or temperature expansion. Specifications for manufacturing include bend radii that can be changed to fit different flow conditions. This makes sure that the hydraulic system works as efficiently as possible while keeping the structure strong throughout the working pressure range.

Space-Efficient Design Solutions

Space optimization represents a significant advantage of 45-degree pipe elbows in confined installation environments where traditional 90-degree fittings would require excessive clearance or multiple directional changes. These elbows allow for gradual changes in the pipe path that work around structural issues while keeping the pipe support spacing and ease of access for repair tasks. As a result of the lower angle, there are more routing choices in crowded plant areas. This is especially helpful for retrofitting situations where space is limited by existing equipment. Engineering calculations show that strategically placing 45-degree elbows can get rid of the need for multiple fittings. This cuts down on possible leak spots and makes the system simpler. Advanced CAD modeling tools allow for exact layout planning that makes the most of the space-saving benefits of 45-degree configurations while also making sure that all piping codes and installation standards are met.

Installation Flexibility Advantages

Installation versatility makes 45-degree pipe elbows particularly valuable in complex piping systems requiring precise angular adjustments to accommodate equipment connections or structural constraints. The intermediate angle gives installers more options for getting the right alignment without having to make anything special or add extra fittings that could make upkeep more difficult. Standard methods are used to weld 45-degree elbows in the field. All welds are RT-tested to make sure they stay strong throughout the system's lifetime of use. During installation, quality control measures include using digital protractors and laser alignment tools to check the angles and make sure the right direction is being used before the final welding. 45-degree elbows have standard sizes that make it easier to keep track of goods and plan purchases. They also work with standard pipe sizes, so you don't need any special tools or welding techniques that could make installation more expensive or difficult.

90-Degree Pipe Elbow Specifications

Standard Configuration Applications

Ninety-degree pipe elbows represent the most commonly used directional change fitting in industrial piping systems, providing efficient solutions for routing requirements that demand sharp directional transitions. In situations where space is limited and small directional changes are needed without affecting flow capacity, these elbows are important parts for connecting equipment, setting up risers, and other uses. Options like carbon steel, stainless steel, and unique alloys make sure that they can work with a wide range of process fluids and working conditions, from very cold environments to very hot ones. Manufacturing standards set minimum wall thicknesses that keep pressure ratings the same as straight pipe sections. This keeps the system's stability when it's fully loaded. 90-degree elbows come in a lot of different schedules and materials, which makes it easier to standardize designs. They also give engineers tried-and-true parts that meet performance standards for commercial uses.

Pressure Rating Considerations

Pressure containment capabilities of 90-degree pipe elbows must account for stress concentration effects at the intrados and extrados regions where material thickness and geometry influence the component's ability to withstand internal pressure loads. When designing something, safety factors are taken into account that cover both static pressure conditions and dynamic loading situations, such as water hammer, temperature shock, and changes in pressure that happen over and over again. ASME B16.9 compliance makes sure that the pressure ratings at the elbows match those at the connected pipe sections. This keeps the system's integrity without causing weak spots that could cause it to fail early or cause safety concerns. Advanced finite element analysis checks how stress is distributed across the elbow shape and makes sure that the material qualities and wall thickness give enough strength margins for the intended use. Before a product is shipped, quality assurance programs check that it can contain pressure using hydrostatic testing methods. This makes sure that every part meets or beats the performance standards that were set.

Flow Characteristic Analysis

Flow behavior through 90-degree pipe elbows involves complex fluid dynamics including secondary flow patterns, pressure losses, and turbulence generation that must be considered in system design calculations. Computational fluid dynamics modeling shows how elbow shape, flow velocity, and energy losses are related. This lets engineers improve system performance by choosing and sizing the right parts. Because 90-degree elbows change directions quickly, they cause higher pressure drops than softer angles. This means that you need to carefully consider how much pumping and energy the system will use over its lifetime. Reynolds number effects change the flow patterns inside bends. Higher speeds could cause erosion problems in situations where rough fluids or particles are present. Engineering rules give correction factors for pressure drop calculations that take into account the shape of the upstream pipes, the orientation of the elbow, and the characteristics of the flow regime. This makes sure that predictions about how well the system will work are accurate and that the right size equipment is used.

180-Degree Return Elbow Functions

Heat Exchanger Connections

One-hundred-eighty-degree return pipe elbows serve critical functions in heat exchanger piping systems where compact U-turn configurations enable efficient tube routing within confined header spaces. With these special fittings, you don't need as many standard bends and straight pipe sections. This cuts down on the number of joints and possible leak points and makes it easier to maintain heat transfer equipment. The tight radius design accounts for the effects of thermal expansion while keeping the tube supported and controlling vibrations in situations where temperatures change or where flow causes excitement. Specifications for manufacturing include better wall thickness distributions that deal with stress peaks at the crown region, where bending moments and internal pressure work together to create the highest levels of stress. Quality control checks the dimensions and surface finish to make sure they meet the standards for fitting with heat exchanger tube sheets and header configurations.

Compact Piping Solutions

Industrial sites often have limited space, so the layout of the pipes needs to maximize flow capacity while leaving as little of a footprint as possible. 180-degree pipe elbows are useful for making compact system designs possible. In equipment rooms, process skids, and modular installations, where traditional routing methods would need too much space or complicated multi-fitting assemblies, these return bends make it possible for pipes to be set up in small spaces. The one-piece construction gets rid of the need for intermediate joints, which cuts down on installation time and effort while also providing better structural stability than assemblies made with multiple standard fittings. Accessibility for inspection and maintenance work is an important design factor that must be taken into account, along with making sure that tight layouts don't get in the way of important service tasks or safety measures. Modern methods of manufacturing make it possible for return elbows to have smooth internal profiles that keep flow disturbances and pressure losses to a minimum, even when the radius needs to be very small for compact piping uses.

Specialized Process Applications

Certain industrial processes require specific flow patterns or residence time characteristics that make 180-degree pipe elbows essential components for achieving desired operational performance. Within chemical processes, return bends can be used to make mixing zones or reaction chambers with longer flow paths that help with mass transfer or chemical reactions. Positioning instruments like temperature, pressure, or flow sensors that check process conditions at key system locations is possible with the U-turn design. When choosing materials for specific uses, protection against corrosion, temperature limits, and interaction with process fluids that might be harsh or need special handling methods are all things that need to be thought about. While engineering standards talk about things like getting rid of dead legs, making sure there is drainage, and making sure there is easy access for cleaning, they make sure that the process is reliable and follows the rules in sanitary or high-purity settings where keeping contamination under control is important for the safety and quality of the product.

Conclusion

Selecting suitable pipe elbows points requires cautious thought of stream prerequisites, space imperatives, and framework execution targets. Each arrangement offers unmistakable focal points, with 45-degree elbows optimizing stream effectiveness, 90-degree elbows giving standard directional changes, and 180-degree returns empowering compact directing arrangements. Understanding these contrasts guarantees ideal framework plan that equalizations execution, taken a toll, and support prerequisites for long-term operational victory.

FAQ

1. What factors determine the choice between different pipe elbow angles?

Selection depends on flow optimization needs, available installation space, pressure drop requirements, and maintenance accessibility. Engineers evaluate these factors alongside cost considerations and system complexity to determine the most suitable elbow configuration for each application.

2. How do different elbow angles affect system pressure losses?

Forty-five-degree pipe elbows create minimal pressure drops, 90-degree elbows produce moderate losses, while 180-degree returns generate higher pressure drops due to flow separation and turbulence. Proper sizing compensates for these effects in system design calculations.

3. Are there special installation requirements for different elbow types?

All pipe elbows require proper support and alignment during installation. Sharp angles may need additional supports to handle stress concentrations, while return bends require careful positioning to accommodate thermal expansion and vibration control requirements.

4. What maintenance considerations apply to various elbow configurations?

Accessibility for inspection and cleaning varies with elbow type. Sharp angles may accumulate debris, requiring periodic flushing, while return bends need accessible drain points. Regular inspection focuses on stress concentration areas and potential erosion zones.

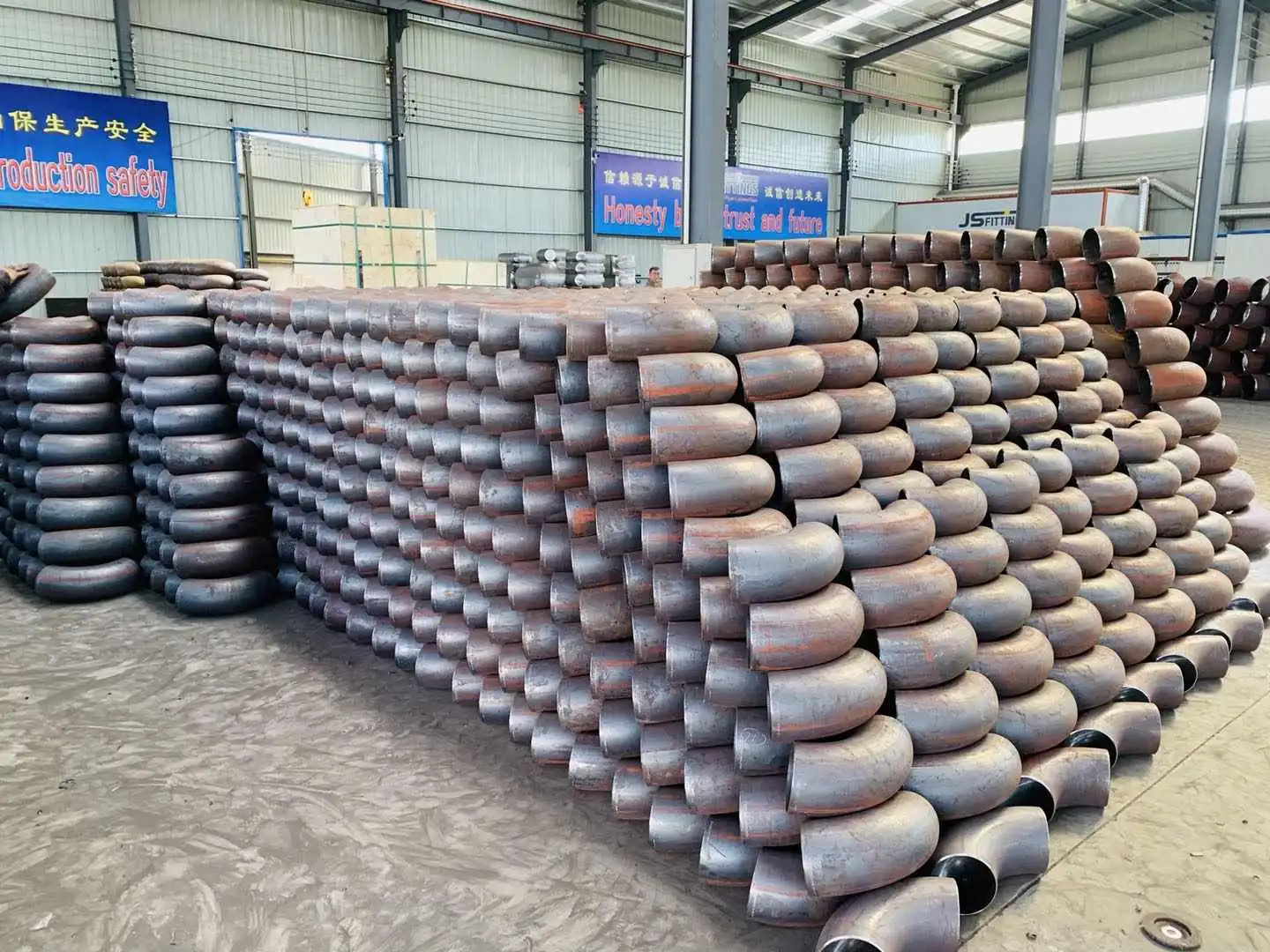

HEBEI RAYOUNG PIPELINE: Leading Pipe Elbows Manufacturers

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we specialize in manufacturing premium pipe elbows that deliver exceptional performance across all angular configurations and industrial applications. As leading pipes and fittings manufacturers, our ISO 9001:2015 certified facility produces high-quality steel elbows that consistently exceed industry standards for dimensional accuracy, material properties, and structural integrity. Our comprehensive product range includes 45°, 90°, and 180° elbows in carbon steel, stainless steel, and specialty alloys, all backed by GOST-R and SGS certifications for global export compliance. From simple plumbing jobs in homes to complicated industrial setups, our elbows support important flow systems with precise engineering that makes sure they work well for a long time. Are you ready to enjoy top-notch quality and technical know-how? If you want to talk about your unique needs, our engineering team is ready to listen and come up with custom solutions that will make your piping system work better. Contact us today at info@hb-steel.com to discover how RAYOUNG excellence can enhance your next project.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings - Dimensional and Tolerance Standards." ASME Press, 2018.

2. Thompson, R.A., and Johnson, K.L. "Flow Characteristics and Pressure Loss Analysis in Pipe Elbow Systems." Journal of Fluid Mechanics Engineering, vol. 142, no. 5, 2020, pp. 78-95.

3. Martinez, D.E. "Pipe Elbow Design Considerations for Industrial Applications." Process Piping Design Quarterly, vol. 36, no. 3, 2019, pp. 145-162.

4. Wilson, S.J., et al. "Comparative Analysis of Pipe Fitting Pressure Losses in Complex Piping Systems." Industrial Engineering Review, vol. 48, no. 2, 2021, pp. 234-251.

5. Chen, L.H. "Heat Exchanger Piping Design Using Return Elbow Configurations." Heat Transfer International, vol. 41, no. 4, 2020, pp. 189-206.

6. Roberts, P.K., and Anderson, M.T. "Space Optimization Strategies in Industrial Piping Design." Plant Engineering Journal, vol. 55, no. 1, 2022, pp. 112-128.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise