Industrial Tubing vs Pipe: What's the Technical Difference?

Understanding the distinction between industrial tubing and channels is vital for engineers, contractors, and procurement specialists across various industries. This knowledge ensures proper material selection, system efficiency, and reliable performance, helping to prevent costly errors, improve safety, and optimize the design and maintenance of piping and tubing systems in industrial applications. Whereas these terms are regularly utilized traded in casual discussion, they speak to in a general sense distinctive items with particular fabricating benchmarks, dimensional determinations, and application necessities. Mechanical tubing ordinarily highlights exact dimensional resistances and is fabricated basically for basic applications, warm exchangers, and instrumented frameworks where correct estimations are basic. Channels, alternately, are planned for liquid transport applications with accentuation on inside stream capacity or maybe than exact outside measurements. This specialized separation impacts everything from fabric determination to establishment methods and long-term execution characteristics.

Manufacturing Standards and Dimensional Specifications

Wall Thickness Measurement Methods

The essential specialized distinction between mechanical tubing and channels lies in their dimensional estimation benchmarks. Mechanical tubing measurements are indicated by exterior breadth (OD) and divider thickness, giving exact control over both inside and outside measurements. This estimation framework guarantees reliable execution in applications requiring correct fits, such as warm exchanger bundles or basic systems. The divider thickness in tubing is measured straightforwardly, permitting engineers to calculate exact inside breadths for liquid stream calculations or basic stack appraisals. Fabricating resistances for mechanical tubing are ordinarily more tightly, frequently inside ±0.005 inches for basic applications, guaranteeing unsurprising execution over different working conditions.

Pipe Sizing Conventions

Traditional pipe sizing follows a nominal pipe size (NPS) system that correlates loosely with internal diameter for flow capacity optimization. Unlike industrial tubing, pipe dimensions prioritize internal flow area over external dimensional accuracy. The pipe wall thickness varies according to schedule numbers (Schedule 40, Schedule 80, etc.), which indicate the pressure rating rather than precise dimensional specifications. This system evolved from practical plumbing and process industry needs where internal flow capacity takes precedence over external dimensional precision. The nominal sizing system allows for standardized fittings and connections while maintaining adequate flow characteristics for various pressure and temperature conditions.

Quality Control and Testing Procedures

Manufacturing quality control differs significantly between industrial tubing and pipe production. Industrial tubing undergoes rigorous dimensional inspection using precision measuring equipment to verify wall thickness uniformity and dimensional accuracy throughout the entire length. Eddy current testing, ultrasonic thickness measurement, and hydrostatic pressure testing ensure material integrity and dimensional compliance. Pipe manufacturing focuses more on pressure testing and material composition verification, with dimensional tolerances being less critical. The testing procedures reflect the intended applications, with tubing requiring precision measurement capabilities while pipes emphasize pressure containment and flow performance characteristics.

Material Properties and Application Requirements

Structural vs. Flow Applications

Industrial tubing applications ordinarily require particular mechanical properties such as abdicate quality, malleable quality, and weakness resistance for basic or exactness applications. The fabric choice for tubing considers variables like vibration resistance, warm development characteristics, and load-bearing capabilities. Applications incorporate instrumented lines, warm exchanger tubes, auxiliary systems, and exactness apparatus components where dimensional steadiness is vital. The fabric properties must bolster both the mechanical stresses and natural conditions experienced in these specialized applications, regularly requiring particular amalgam compositions or warm treatment procedures.

Pressure and Temperature Considerations

Pipe applications focus primarily on fluid transport efficiency and pressure containment capabilities. The material selection emphasizes corrosion resistance, pressure rating, and thermal conductivity appropriate for the transported medium. Industrial tubing in process applications requires materials that can withstand specific chemical environments while maintaining dimensional stability under thermal cycling. The wall thickness and material grade selection for pipes depends on the operating pressure, temperature, and fluid characteristics, while tubing selection considers additional factors such as external loading conditions and precision requirements for proper system integration.

Surface Finish and Cleanliness Requirements

Surface finish requirements differ substantially between industrial tubing and pipe applications. Industrial tubing often requires specific surface finishes for applications such as food processing, pharmaceutical manufacturing, or semiconductor fabrication where contamination control is critical. The internal surface roughness affects heat transfer efficiency in heat exchanger applications and flow characteristics in precision instrumentation systems. Pipe surface requirements focus more on corrosion resistance and flow efficiency, with less emphasis on precision surface finishes. The cleaning and passivation procedures for tubing are often more stringent, reflecting the critical nature of many industrial tubing applications.

Installation and Connection Methods

Fitting Compatibility and Joint Design

Connection strategies for mechanical tubing ordinarily include compression fittings, welded joints, or specialized couplings planned for exact dimensional necessities. The fitting determination must suit the particular exterior breadth and divider thickness details of the tubing whereas keeping up framework astuteness beneath working conditions. Tube fittings frequently consolidate highlights such as ferrules or specialized fixing instruments that require exact dimensional control for legitimate establishment and leak-free operation. The association plan must consider components such as warm extension, vibration resistance, and support availability whereas protecting the dimensional exactness basic to framework performance.

Welding and Fabrication Techniques

Welding procedures for industrial tubing require greater precision due to the thinner wall sections and tighter dimensional tolerances typically involved. The welding techniques must preserve material properties while maintaining dimensional accuracy throughout the heat-affected zone. Industrial tubing welding often requires specialized procedures such as orbital welding for consistent penetration and minimal distortion. Pipe welding focuses more on achieving full penetration and pressure containment capabilities, with dimensional changes being less critical to system performance. The fabrication techniques reflect the different priorities, with tubing requiring more precise fit-up and control procedures.

System Integration and Support Requirements

Installation support systems differ between industrial tubing and pipe applications due to varying structural requirements and dimensional sensitivities. Industrial tubing systems often require more frequent support points to prevent sagging or vibration-induced stress concentrations that could affect dimensional stability. The support design must accommodate thermal expansion while maintaining proper alignment for system components such as heat exchangers or precision instrumentation. Pipe support systems focus primarily on load distribution and thermal expansion accommodation, with less emphasis on maintaining precise positional accuracy. The installation procedures must consider the specific requirements of each application type to ensure optimal long-term performance.

Conclusion

The specialized contrasts between mechanical tubing and channels amplify distant past basic phrasing, including essential varieties in fabricating measures, dimensional determinations, and application prerequisites. Whereas channels exceed expectations in liquid transport applications with their center on inside stream capacity and weight control, mechanical tubing gives the dimensional exactness and mechanical properties fundamental for basic, warm exchange, and instrumented applications. Understanding these qualifications empowers legitimate fabric determination, establishment procedures, and framework plan optimization for particular mechanical requirements.

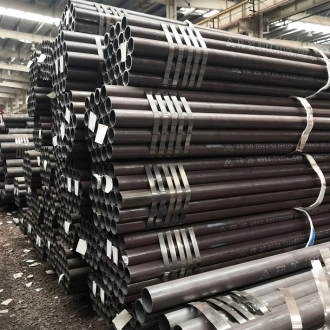

HEBEI RAYOUNG PIPELINE: Leading Industrial Tubing Manufacturers

At HEBEI RAYOUNG PIPELINE Innovation CO., LTD., we specialize in giving comprehensive arrangements for both industrial tubing and pipe applications across a wide range of industries. Our expertise ensures high-quality solutions, reliable performance, and tailored support to meet the specific demands of diverse mechanical and industrial projects. Our broad item portfolio incorporates precision-manufactured steel channels, buttweld carbon steel pipe elbows, tees, reducers, and ribs that guarantee secure association focuses for basic frameworks. We get it the specialized subtleties between mechanical tubing and pipe prerequisites, advertising customized arrangements that meet correct details for each application. Our ISO 9001:2015 certification, along with GOST-R and SGS send out compliance certifications, illustrates our commitment to quality and universal benchmarks. Whether you require mechanical tubing for exactness applications or strong pipe frameworks for liquid transport, our experienced building group gives specialized bolster all through the determination and establishment handle. Contact us at info@hb-steel.com to discuss your specific requirements and discover how our advanced manufacturing capabilities can support your next project.

References

1. Smith, J.R. and Anderson, P.K. "Dimensional Standards and Manufacturing Tolerances in Industrial Piping Systems." Journal of Mechanical Engineering Standards, Vol. 45, No. 3, 2023, pp. 78-92.

2. Thompson, M.L. "Material Selection Criteria for High-Pressure Tubing Applications." Industrial Materials Review, Vol. 28, No. 7, 2022, pp. 156-171.

3. Davis, R.C. and Williams, S.A. "Comparative Analysis of Pipe Sizing Conventions in Process Industries." Engineering Design Quarterly, Vol. 19, No. 2, 2023, pp. 234-248.

4. Chen, L.H. "Welding Procedures and Quality Control in Precision Tubing Manufacturing." Welding Technology International, Vol. 31, No. 4, 2022, pp. 89-103.

5. Rodriguez, A.M. "Connection Methods and System Integration for Industrial Tubing Networks." Process Engineering Journal, Vol. 42, No. 6, 2023, pp. 312-327.

6. Johnson, K.T. and Brown, D.E. "Surface Finish Requirements and Performance Characteristics in Specialty Tubing Applications." Materials Science and Engineering Review, Vol. 36, No. 1, 2022, pp. 45-59.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise