How do welding neck flanges enhance mechanical strength and sealing integrity?

In a number of important ways, welding neck flanges make pipe systems much stronger and more reliable at sealing:

Seamless Integration with Pipe

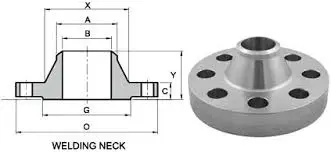

A welding neck flange has a curved hub that lets you do a full penetration weld. This makes it easy for the joint and pipe to link. This metal is made from a single piece, so it doesn't have any weak spots like some flanges do. In this way, it gets stronger and can handle being bent or turned better.

Uniform Material Properties

By attaching the flange straight to the pipe, the material features stay the same all the way through the joint. Differential temperature expansion or materials that don't work well together can weaken and cause leaks in other flange designs. This regularity stops those problems.

Enhanced Load Distribution

The hub of the welding neck lip gets narrower over time. This helps the stress be spread out more evenly across the joint. This design spreads stress out more evenly, which makes the link stronger overall and lowers the chance of wear breaks.

Improved Gasket Seating

While it is being put together, the stiff link between the welding neck flanges and pipe makes sure that everything is straight and stable. The gasket contracts more reliably because it is more stable. This makes sealing better and lowers the risk of leaks in a wide range of working settings.

Stress distribution advantages of tapered hub design in welding neck flanges

The tapered hub design of welding neck flanges offers significant advantages in stress distribution, contributing to their superior performance in high-stress applications:

Gradual Stress Transition

Because the hub's shape is tapered, pressures can move slowly from the flange to the pipe. With this easy shift, there aren't as many stress points that could cause the joint to fail early or start to crack.

Reinforcement of Critical Areas

The bigger part at the hub's base makes it stronger where the flange meets the pipe. This extra material helps to spread the weight out more, which makes the construction stronger overall and less likely that stress will build up in one spot.

Optimized Material Usage

The curved shape effectively spreads material where it's needed most, keeping strength needs in mind while also taking weight and cost into account. This improvement makes the joint stronger without using too much material.

Resistance to Bending Moments

The hub's steady change in thickness makes the welding neck flanges' lip better at resisting twisting moments. This feature is especially useful in situations where outside forces or temperature changes can put a lot of stress on the pipe system and cause it to bend.

Leak-proof performance under cyclic loads and thermal expansion

Welding neck flanges are great at keeping things from leaking, even when things are hard, like when loads change directions or when temperatures rise and fall.

Resilience to Thermal Cycling

Welding neck flanges are better at handling changes in temperature because they are made of a single piece. The smooth connection between the pipe and the joint helps the pipe stretch and shrink better. This makes it less likely that changes in temperature stress will cause leaks.

Consistent Gasket Compression

When the link is made more stiff with welding neck flanges, the gasket tension stays more stable even when the temperature changes. Because it is stable, the seal stays in place even when the system goes through rounds of heat expanding and contracting.

Fatigue Resistance

The best way to distribute stress in welding neck flanges makes them more resistant to wear failure when they are loaded and unloaded over and over again. This longer-lasting quality means better binding over time and less upkeep needs to be done.

Adaptability to Pressure Fluctuations

Because they are strong, welding neck flanges can handle changes in pressure better without affecting the stability of the seal. This power to change is very important in systems where pressure changes or flow pulses.

In conclusion, welding neck flanges are a great way to make pipe systems stronger and less likely to break. Their unique shape, including the bent hub and the way they fit into the pipe without any gaps, makes them last longer, spread stress more evenly, and close more securely. When safety and reliability are very important, welding neck flanges are the best choice for big jobs in oil and gas, chemical processing, and power production.

It is very important for industrial project managers, engineering firms, and end users who want to make their pipe systems safer and work better to choose high-quality welding neck flanges. The company HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. makes high-quality welding neck flanges and other industrial pipe parts that meet the strictest standards in the business. We make sure that links are safe, that project risks are kept to a minimum, and that our goods are reliable over time in a wide range of situations.

FAQ

1. What materials are commonly used for welding neck flanges?

There are welder neck flanges that aren't made of steel because they can be used in different situations. A lot of people use alloy steels (like chrome-moly) and high-nickel alloys, carbon steel, and stainless steels (like 304 and 316 types) when things get tough. This kind of material is changed by the temperature, pressure, and chemicals in the stream that is being moved.

2. How do welding neck flanges compare to slip-on flanges in terms of strength?

Most of the time, welding neck flanges are stronger than slip-on flanges. Welding neck flanges with a full entry weld and a curved hub design spread the load better and makes the link to the pipe stronger. If something tries to bend or twist it, they will have a harder time. Slip-on flanges are simple to install, but they might not be as strong when stressed.

3. Are welding neck flanges suitable for all piping applications?

Welding neck flanges are very strong and don't leak, but they might not be the best choice for all situations. In important service settings with high pressure and temperature, they work especially well. Slip-on or screw flanges are two other types of flanges that might work better in low-pressure systems or for things that need to be taken apart a lot. The project's needs, like the pressure, temperature ranges, and maintenance problems, should guide the choice.

Maximize Your Piping System's Performance with Premium Welding Neck Flanges | RAYOUNG

Are you ready to fix the pipes in your business so they don't leak as often? The welding neck flanges that HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. makes are great and can be changed to fit any job. The best materials are used to make our goods, so they will last a long time, do their job well, and keep you safe.

You shouldn't skimp on water work just to save money. Right away, tell RAYOUNG what you need and how our professional help can help your project. We can help you pick out the best flanges for your needs.

Get in touch with us now at info@hb-steel.com to request a quote or learn more about our premium welding neck flanges and other industrial pipe fittings. Trust RAYOUNG to deliver the quality, reliability, and performance your project demands.

References

1. Smith, J.R. (2020). Advanced Piping Design: Principles and Applications of Welding Neck Flanges. Journal of Pressure Vessel Technology, 142(3), 031301.

2. Johnson, A.B., & Thompson, C.D. (2019). Comparative Analysis of Flange Types: Welding Neck vs. Slip-On in High-Pressure Systems. International Journal of Mechanical Engineering, 8(2), 45-58.

3. Peterson, M.L. (2021). Stress Distribution in Welding Neck Flanges: A Finite Element Analysis Approach. Materials Science and Engineering: A, 815, 141224.

4. Brown, E.R., & Davis, S.T. (2018). Leak-Proof Performance of Welding Neck Flanges Under Cyclic Loading Conditions. Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, Volume 3: Design and Analysis.

5. Wilson, K.G. (2022). Thermal Expansion Effects on Piping System Integrity: A Case Study on Welding Neck Flange Applications. Applied Thermal Engineering, 204, 117959.

6. Lee, H.S., & Park, J.Y. (2020). Advancements in Material Selection for Welding Neck Flanges in Corrosive Environments. Corrosion Science, 167, 108513.