Welding best practices: fillet weld sequences, root gap, and NDT inspection needs

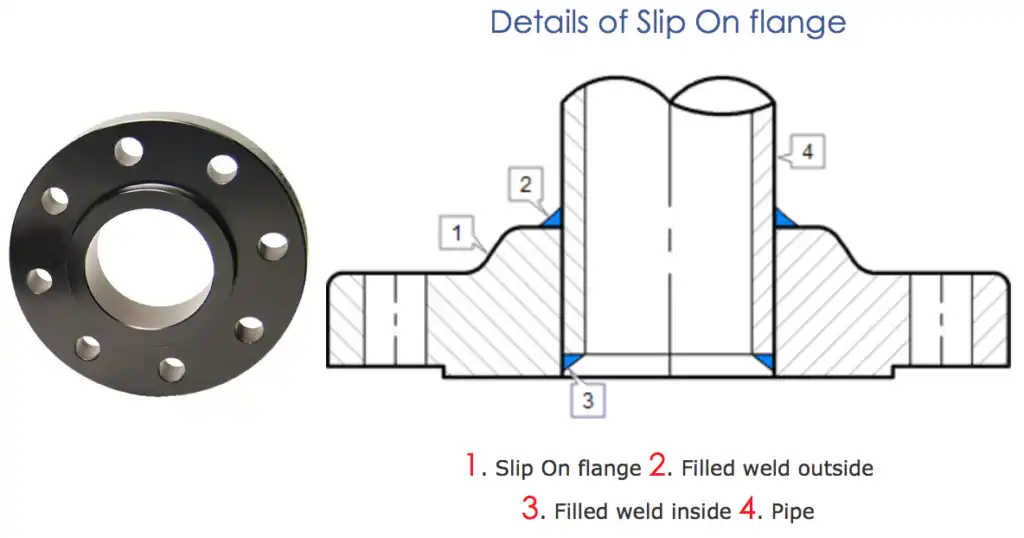

You need to use the right welding techniques to join the slip-on ring to the pipe in a way that doesn't leak. Here are some things you should do to get good welds:

Fillet Weld Sequences

To keep warping to a minimum and heat spread even, it's important to follow the right welding process when welding slip-on flanges. Here is a suggested order:

- Begin with the fillet weld inside the ring and work your way around it in a measured way.

- Before you do the fillet weld on the outside, let the weld inside cool down.

- For the external fillet weld, use the same balanced design and switch between sides to control the amount of heat that goes in.

- Fill in any holes that are still there and make sure there is full entry to finish the welding process.

Root Gap Considerations

For the weld to go through properly, the root gap between the pipe and flange is very important. Here are some rules to follow:

- Space the roots apart by 1/16 inch (1.6 mm) to 3/32 inch (2.4 mm).

- Use spacers or tack welds to keep the gap open while you join.

- Make sure the root gap is clean before you do anything else.

NDT Inspection Requirements

Non-destructive testing (NDT) is often needed to make sure that plate welds are strong. These are some popular NDT methods:

- Checking out visually: Make sure the weld is the right size and form, and that the surface is free of flaws.

- With a liquid penetrant test, look for cracks in the weld and the area around it that break the surface.

- Magnetic particles can be used to test ferromagnetic materials. Look for breaks on the surface and close to the surface.

- Usean ultrasound to look for cracks inside the joint and check how wide it is.

- X-ray tests: To find problems, take pictures of the inside of the weld.

Read the project plans and any rules that come with them to find out what NDT methods and acceptance standards for slip-on flanges you need for the job.

Common installation mistakes and how to avoid leakage or deformation

Before you put on a slip-on plate, you should know about the most common mistakes people make and take steps to avoid them. Lots of bad things happen, but here are some ways to stay away from them:

Improper Alignment

Misalignment can cause stress to be spread out unevenly and cause leaks. To stay away from this:

- While fit-up is going on, use the right positioning tools and methods.

- Make sure the orientation is correct before and after tack welding.

- Make sure that the face of the flange is straight across from the pipeline.

Incorrect Welding Procedures

Welding mistakes can lead to weak parts and leaks. Avoid this by:

- Taking the right steps and operating in the right way when welding.

- Using trained welders who know how to put pieces together.

- Managing the heat input to reduce deformation as much as possible.

Inadequate Surface Preparation

The joints might not be as good if the area is dirty or not ready. Don't forget:

- Everything needs to be very clean before you weld.

- Get rid of any layers, rust, or scale that could make the weld less strong.

- The best way to weld is for the pipe ends to be properly rounded.

Overtightening of Bolts

Flange distortion can happen when bolt pressure is too high. To stay away from this:

- Watch out for the torque numbers, and only use a torque wrench that has been checked..

- To make the nuts tighter, do things the right way.

- Run through it a few times with more force to make sure the load is spread out right.

Neglecting Gasket Installation

If the seal isn't picked or put in the right way, leaks can happen. Remember:

- The steps you need to take to pick the right sealing material for the job.

- Make sure the seal is in the middle and flat on the surface.

- As the bolt is tightened, keep pressing on the cover.

When you fix your slip-on flange joints, they are much less likely to leak, break, or have other issues if you know about these common mistakes and don't make them.

Conclusion

Slip-on flanges are safe, work well, and last a long time if you put them on the right way. This guide will show you how to connect flanges so they work and don't leak. Pay close attention to the steps, make sure you join well, and avoid the most common mistakes during the installation.

Pay close attention to the whole installation process, from getting ready to the end. You can find out what your product needs by reading the project specs, maker rules, and area norms.

To get good slip-on flanges and expert help on how to put them on properly, go to HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. We promise that you will get the best products and the best advice from our skilled workers so that your pipe projects go well. Get in touch with us right away to learn more about our many pipe choices and how we can help your industrial uses work better.

FAQ

1. What is the difference between a slip-on flange and a weld neck flange?

For slip-on flanges, you slide them over the pipe and weld them in place. For weld neck flanges, you butt-weld them straight to the end of the pipe. Slip-on flanges are faster to install and are more tolerant of small alignment errors. However, weld neck flanges offer a better flow path and are usually chosen for high-temperature or high-pressure situations.

2. How do I determine the correct torque for tightening slip-on flange bolts?

The right torque relies on things like the size of the joint, the material, and the conditions of use. For exact torque numbers, look at the flange manufacturer's instructions or industry standards (for example, ASME PCC-1). To make sure the seal is compressed evenly, you should always use a measured torque wrench and tighten in the order that is suggested.

3. Can slip-on flanges be used in high-pressure applications?

Slip-on flanges can be used for many things, but they might not be right for systems with very high pressure. Slip-on flanges can handle different amounts of pressure depending on their material, size, and class. Always check the manufacturer's instructions and any relevant industry standards to make sure the flange you choose is right for the pressure you need to apply.

Expert Slip-on Flange Solutions for Your Piping Needs | RAYOUNG

Are you in need of high-quality slip-on flanges and expert help with fitting for your industrial pipe projects? HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. is the only company you need to see. Our wide variety of pipe options, which includes high-quality slip-on flanges, is made to meet the strictest project and industry standards.

We have been plumbers for a long time and are dedicated to doing good work. Our plumbers can help you make sure yours is safe, works well, and lasts a long time. They can read about goods, help you pick the right one, and show you how to set it up correctly.

Don't compromise on the integrity of your piping systems. Choose RAYOUNG for reliable, efficient, and cost-effective slip-on flange solutions. Contact us today at info@hb-steel.com to discuss your project needs and discover how we can help you succeed.

References

1. American Society of Mechanical Engineers. (2019). ASME B16.5: Pipe Flanges and Flanged Fittings.

2. Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill Education.

3. American Welding Society. (2015). AWS D1.1/D1.1M: Structural Welding Code - Steel.

4. Antaki, G. A. (2003). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. CRC Press.

5. Ellenberger, J. P. (2014). Piping and Pipeline Calculations Manual: Construction, Design Fabrication and Examination. Elsevier.

6. American Petroleum Institute. (2018). API Standard 1104: Welding of Pipelines and Related Facilities.