Forged vs. Cast Pipe Fittings: Which One Should You Choose

Choosing between cast and forged pipe fittings is an important decision that affects the safety, dependability, and long-term performance of systems in many industrial settings. Mechanical characteristics, pressure ratings, cost structures, and applicability to certain operating situations are where the two production methods diverge significantly, yet both methods yield working components. The mechanical deformation of hot metal under intense pressure produces forged pipe fittings, which are perfect for uses involving high temperatures and pressures because they align the grain structure and have exceptional strength. For lower-pressure systems and complicated geometries, cast fittings provide design freedom and cost benefits because they are made by pouring molten metal into molds. Engineers and procurement specialists can optimize safety, reliability, and project budgets by understanding the economic considerations, performance capabilities, and distinct characteristics of each manufacturing method. This knowledge also ensures compliance with applicable standards and specifications.

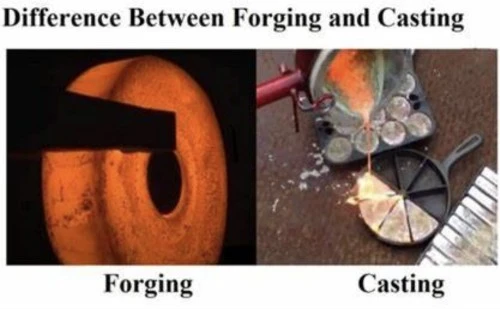

Manufacturing Process Differences and Material Properties

Forging Process and Grain Structure Advantages

To form metal billets into desired shapes, forgers heat them to a point where they become pliable, and then they use hammers or presses to impart massive compressive forces. In contrast to as-cast materials, mechanically worked metals have enhanced directional strength thanks to a change in the metal's internal grain structure that aligns crystalline patterns in the direction of applied stresses. Forged materials are denser, have more predictable mechanical properties, and are structurally more robust than cast materials because the compression during forging removes internal voids, porosity, and discontinuities. As a result of their refined grain structure, which includes smaller and more homogeneous crystals, forged pipe fittings are more resistant to stress or impact loading, and they are also more durable and ductile. Plastic deformation's work hardening effect boosts yield and tensile strengths relative to the original material, allowing for improved load-carrying capacity in rigorous applications. Thermoregulation during heating and shaping, cooling at a steady rate to avoid thermal shock, and heat treatments after forging, like normalizing or stress relieving, improve the mechanical qualities and dimensional stability of the finished product, making it ideal for use in demanding service conditions.

Casting Process and Design Flexibility

Cast pipe fittings are manufactured by melting raw materials in furnaces, then pouring the molten metal into sand molds, permanent metal molds, or investment casting shells that define the final component geometry. The casting process offers exceptional design flexibility, accommodating complex internal passages, intricate external features, and geometric configurations difficult or impossible to achieve through forging operations. Sand casting, the most common method for large fittings, uses expendable molds created from bonded sand mixtures, allowing economical production of components in various sizes without substantial tooling investment. The solidification process in casting creates different metallurgical characteristics compared to forging, with grain structure developing as metal cools from liquid to solid state without the beneficial mechanical working that aligns grains in forged pipe fittings. Porosity, shrinkage cavities, and inclusions represent potential casting defects that quality control procedures must identify and eliminate through careful process control, proper gating design, and comprehensive non-destructive testing ensuring component integrity.

Comparative Mechanical Properties and Testing Standards

Mechanical property comparisons between forged pipe fittings and cast alternatives reveal significant performance differences influencing application suitability and safety margins. Forged fittings typically exhibit 20-30% higher tensile strength, superior impact toughness particularly at low temperatures, and enhanced fatigue resistance under cyclic loading compared to cast fittings of equivalent material grades. The absence of porosity and directional grain alignment in forged components provides more predictable failure modes with ductile behavior offering warning signs before catastrophic failure. Industry standards including ASTM A105 for forged carbon steel fittings and ASTM A216 for cast carbon steel fittings establish minimum mechanical property requirements, chemical composition limits, and testing protocols ensuring components meet baseline performance criteria. Non-destructive examination using ultrasonic testing, radiography, or magnetic particle inspection detects internal discontinuities or surface defects that could compromise service performance, with acceptance criteria varying based on fitting pressure class and application severity.

Application Suitability and Performance Characteristics

High-Pressure and High-Temperature Applications

High-pressure piping systems operating above 1500 psi or high-temperature service exceeding 400°F typically specify forged pipe fittings due to superior mechanical properties and enhanced safety margins under extreme conditions. The dense, directionally aligned grain structure in forged components resists pressure-induced stress more effectively than cast alternatives, reducing risk of catastrophic failure in systems where leaks could cause injuries, environmental damage, or production losses. Power generation facilities including fossil fuel plants and nuclear stations rely extensively on forged pipe fittings for steam systems, feedwater circuits, and other critical applications where component failure consequences are severe. Petrochemical plants processing hydrocarbons under pressure utilize forged fittings in cracking units, reformers, and high-pressure reactors where elevated temperatures combined with corrosive process fluids demand maximum material integrity. Offshore oil and gas production platforms exposed to harsh marine environments specify forged pipe fittings providing reliability essential for remote installations where maintenance access is limited and failure consequences are catastrophic.

Cost-Sensitive and Complex Geometry Applications

Cast pipe fittings offer economic advantages for applications where operating conditions fall within their performance capabilities and design complexity benefits from casting's geometric flexibility. Water distribution systems, HVAC installations, and low-pressure process piping operating below 600 psi frequently employ cast fittings providing adequate strength at lower cost than forged alternatives. Municipal wastewater systems utilize ductile iron cast fittings combining good strength, corrosion resistance, and economical pricing for large-diameter underground installations. Fire protection sprinkler systems specify cast fittings meeting pressure requirements while minimizing installed costs. Complex fitting geometries including multi-outlet configurations are often more economically produced through casting methods. Industrial applications accepting somewhat lower safety margins can realize significant cost savings specifying cast fittings for non-critical services where failure consequences are manageable and backup systems provide redundancy.

Corrosive Environment and Special Material Requirements

Material selection for corrosive environments significantly influences the forging versus casting decision. Stainless steel forged pipe fittings in grades 304, 316, and duplex alloys provide excellent corrosion resistance for chemical processing, pharmaceutical manufacturing, and food production applications requiring sanitary conditions. Exotic alloys including Hastelloy, Inconel, and Monel are commonly available as forged pipe fittings serving extremely corrosive conditions. The dense structure of forged fittings minimizes surface porosity reducing crevice corrosion risk in chloride-bearing environments where pitting and stress corrosion cracking threaten component integrity. Marine applications alternating between seawater immersion and atmospheric exposure benefit from forged pipe fittings resisting corrosion fatigue where cyclic stress combines with aggressive environment accelerating deterioration.

Selection Criteria and Decision Framework

Pressure Rating and Safety Requirements

Pressure rating requirements represent the primary technical criterion distinguishing when to specify forged pipe fittings versus cast alternatives. Industry standards establish pressure-temperature ratings for fittings based on material grade, wall thickness, and manufacturing method, with forged fittings consistently rated for higher pressures than cast equivalents. ASME B16.11 forged pipe fittings are available in 2000, 3000, and 6000 lb pressure classes serving high-pressure applications, while cast fittings typically limit to 300 lb class. Safety critical applications where fitting failure could endanger personnel justify specifying forged pipe fittings providing maximum reliability regardless of actual operating pressure. Risk assessment methodologies evaluating failure probability guide fitting selection decisions, with high-risk scenarios warranting premium forged components.

Economic Analysis and Budget Constraints

Economic considerations significantly influence fitting selection decisions, requiring analysis balancing initial procurement costs against lifecycle value and reliability benefits. Forged pipe fittings typically cost 50-200% more than cast equivalents depending on size, material grade, and pressure class. Value engineering reviews identify opportunities to employ cast fittings in non-critical services while reserving forged components for applications where their superior properties justify premium pricing. Total cost of ownership analysis incorporates not only initial procurement but also installation labor, maintenance frequency, expected service life, and replacement costs. The enhanced reliability of forged pipe fittings may justify higher initial cost through reduced maintenance interventions and extended service life.

Industry Standards and Client Specifications

Client specifications and industry practices often dictate fitting selection regardless of technical analysis. The oil and gas industry overwhelmingly specifies forged pipe fittings for hydrocarbon service based on safety culture emphasizing maximum reliability. Power generation utilities maintain detailed material standards specifying forged construction for steam systems based on decades of operational experience. Chemical processing facilities reference industry guidelines establishing forged pipe fittings as standard practice for pressure piping systems. Municipal water and wastewater systems commonly accept cast fittings meeting standards for distribution systems where operating pressures remain modest.

Conclusion

Considerations like operating circumstances, pressure requirements, safety, and economics must be thoroughly evaluated when deciding between cast and forged pipe fittings manufacturer forged pipe fittings. When it comes to high-pressure and safety-critical applications, forged pipe fittings are the way to go because of their exceptional strength, dependability, and performance. For systems operating at lower pressures, cast fittings offer an economical alternative. To achieve the best possible balance between performance and budget, it is necessary to understand production variations and application suitability.

HEBEI RAYOUNG PIPELINE: Premium Forged Pipe Fittings Manufacturers and Suppliers

HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD. delivers exceptional quality forged pipe fittings engineered for demanding industrial applications worldwide. Various buttweld carbon steel pipe fittings, such as tees, reducers, flanges, and elbows, are available from our company. These fittings will guarantee that your piping system is well-connected. Solutions for all design needs, from straight configurations to complex angles and flexible joints, are available in our extensive product selection, which includes both forged pipe fittings for high-pressure vital services and quality cast alternatives for cost-sensitive applications. We are one of the top producers of pipes and fittings, and our commitment to quality is supported by certificates from GOST-R and SGS, as well as validation from ISO 9001:2015. Our technical team provides expert guidance helping you select optimal fitting types, materials, and pressure classes matching your specific requirements. Whether you need forged pipe fittings for critical high-pressure systems or economical cast components for general services, HEBEI RAYOUNG PIPELINE delivers dependable materials that stand the test of time. Contact our specialists today at info@hb-steel.com to discuss your project requirements and experience the quality and expertise that distinguishes HEBEI RAYOUNG PIPELINE as your trusted partner.

References

1. American Society of Mechanical Engineers. (2023). ASME B16.11: Forged Fittings, Socket-Welding and Threaded. New York: ASME Press.

2. American Society for Testing and Materials. (2022). ASTM A105/A105M: Standard Specification for Carbon Steel Forgings for Piping Applications. West Conshohocken: ASTM International.

3. American Society for Testing and Materials. (2023). ASTM A216/A216M: Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding. West Conshohocken: ASTM International.

4. Metals Handbook Committee. (2021). ASM Handbook Volume 15: Casting. Materials Park: ASM International.

5. Nayyar, M. L. (Ed.). (2023). Piping Handbook, Ninth Edition. New York: McGraw-Hill Education.

6. Roberts, G. A. & Krauss, G. (2024). Tool Steels: Forging and Heat Treatment Principles, Fifth Edition. Materials Park: ASM International.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise