Corrosion Protection Methods for Pipe Fittings: Galvanizing vs Epoxy Coating vs Cathodic Protection

Industrial pipe systems face constant threats from corrosion, which can compromise structural integrity and lead to catastrophic failures across diverse applications. Selecting appropriate corrosion protection methods for pipe fittings requires careful consideration of environmental conditions, operational parameters, and long-term maintenance requirements. Three primary protection strategies dominate the industry: galvanizing, epoxy coating, and cathodic protection systems. Each method offers distinct advantages for different applications, from chemical processing plants to water distribution networks. Understanding how these protective measures interact with butt weld fittings and other critical components enables engineers to make informed decisions that maximize system longevity while minimizing maintenance costs and operational disruptions.

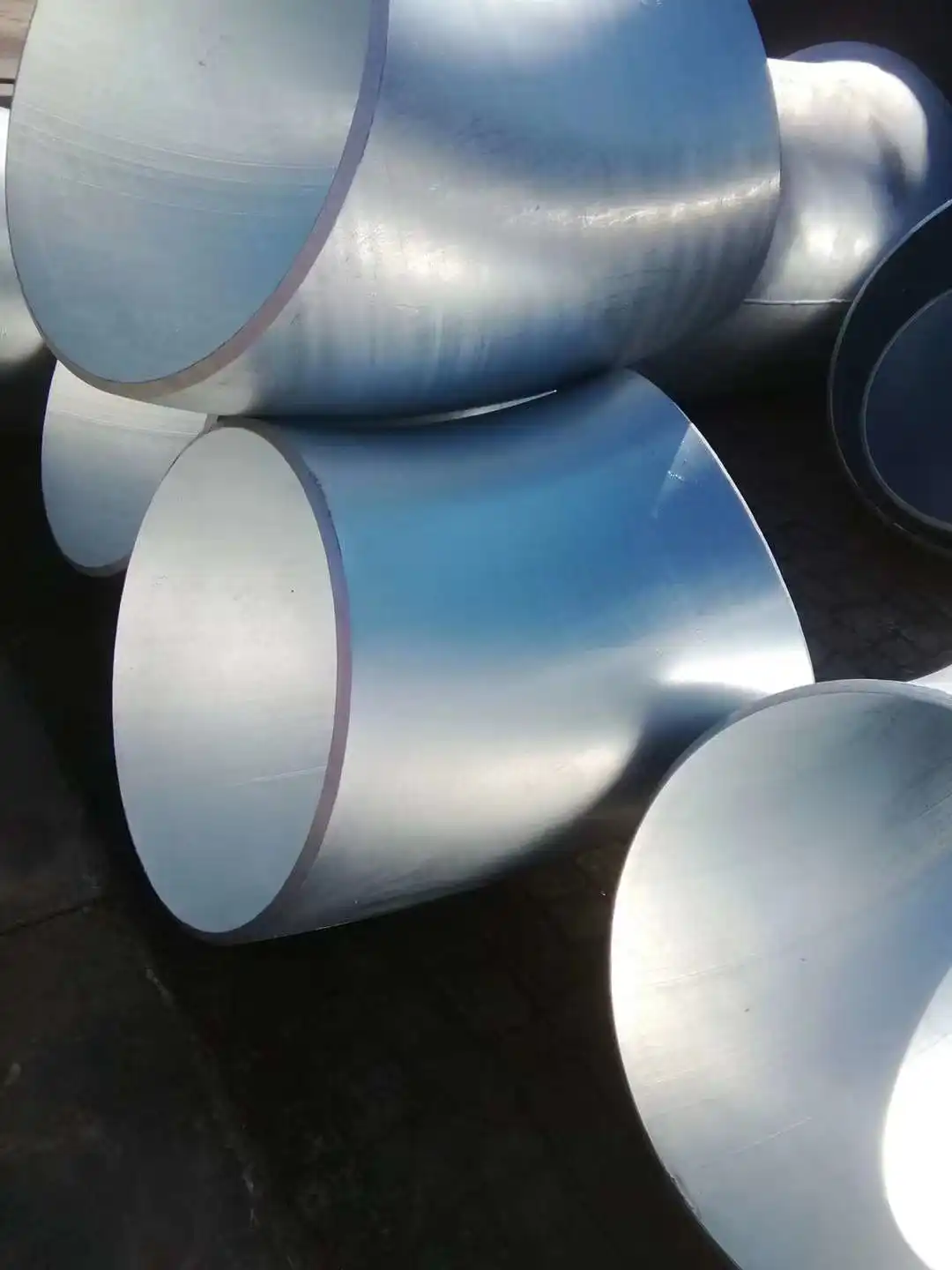

Galvanizing: Hot-Dip Zinc Protection for Long-Term Durability

Galvanizing Process and Application Methods

Hot-dip galvanizing represents one of the most effective corrosion protection methods for industrial pipe fittings, providing a metallurgically bonded zinc coating that serves as both barrier and sacrificial protection. The process involves immersing clean steel components in molten zinc at temperatures around 450°C, creating multiple zinc-iron alloy layers that bond permanently to the base metal. For butt weld fittings, pre-galvanizing preparation requires careful surface cleaning to remove mill scale, rust, and contaminants that could prevent proper zinc adhesion. The galvanizing bath penetrates into crevices and threaded areas, ensuring complete coverage even in complex geometries. After withdrawal from the zinc bath, components develop a protective oxide layer that provides self-healing properties when minor scratches or damage occur during installation or service.

Performance Characteristics in Harsh Environments

Galvanized coatings excel in atmospheric and soil environments where chloride exposure remains moderate, providing decades of maintenance-free service for welded pipe fittings in water treatment facilities, industrial plants, and infrastructure projects. The zinc coating thickness typically ranges from 85 to 200 micrometers, depending on steel composition and immersion time, with thicker coatings providing extended protection periods. In marine environments or areas with high chloride concentrations, galvanized butt weld fittings may require additional protective measures or alternative coating systems. The coating's performance depends on environmental factors including humidity, temperature cycling, and chemical exposure, with proper design considerations ensuring optimal protection throughout the intended service life.

Economic Benefits and Lifecycle Considerations

Galvanizing offers superior economic value through reduced maintenance requirements and extended component life compared to painted systems that require regular recoating cycles. Initial treatment costs are offset by elimination of ongoing maintenance expenses, making galvanized fittings particularly attractive for remote installations or applications where access difficulties make maintenance costly. For large-scale projects utilizing numerous butt weld fittings, galvanizing provides consistent quality and performance characteristics across all components. The coating's durability reduces replacement frequencies and associated downtime costs, while recyclability of zinc-coated steel supports environmental sustainability objectives throughout the facility's operational lifecycle.

Epoxy Coating Systems: Advanced Chemical Resistance Solutions

Coating Application and Curing Technologies

Modern epoxy coating systems provide exceptional chemical resistance and adhesion properties for pipe fittings operating in aggressive industrial environments. Two-component epoxy formulations cure through chemical cross-linking reactions that create dense, impermeable barriers resistant to acids, alkalis, and organic solvents. Application methods include spray, brush, or dip coating techniques, with surface preparation critical for achieving optimal adhesion to butt weld fittings and other steel components. Proper surface preparation involves abrasive blasting to achieve specified cleanliness levels and surface profiles that promote mechanical bonding between coating and substrate. Curing conditions including temperature, humidity, and ventilation must be carefully controlled to ensure complete cross-linking and maximum coating performance.

Chemical Resistance and Temperature Performance

Epoxy coatings demonstrate superior resistance to chemical attack from acids, bases, and organic compounds commonly encountered in processing industries, making them ideal for welded pipe fittings in chemical plants, refineries, and pharmaceutical facilities. Temperature resistance varies with formulation, with standard epoxy systems suitable for continuous service up to 120°C and specialized high-temperature formulations extending service temperatures to 200°C or higher. The coating's impermeability prevents moisture and chemical ingress that could initiate corrosion at the steel interface, while excellent adhesion properties ensure coating integrity under thermal cycling conditions. For butt weld fittings exposed to aggressive chemicals, epoxy systems can be formulated with specific resistance properties tailored to anticipated service conditions.

Maintenance and Repair Considerations

Epoxy-coated systems require periodic inspection and maintenance to address potential damage from mechanical impact, thermal stress, or chemical exposure that could compromise coating integrity. Repair procedures involve surface preparation of damaged areas followed by application of compatible repair materials that restore barrier protection. The coating's excellent adhesion properties facilitate effective repairs when properly executed, extending system life and maintaining corrosion protection. For welded pipe fittings in critical applications, planned maintenance programs should include regular coating condition assessments and proactive repair of minor defects before they compromise system integrity. Advanced inspection techniques including holiday detection and adhesion testing help identify potential problem areas before they lead to corrosion damage.

Cathodic Protection: Electrochemical Corrosion Prevention

Impressed Current and Sacrificial Anode Systems

Cathodic protection systems prevent corrosion by making the protected structure the cathode in an electrochemical circuit, effectively stopping the electrochemical reactions that cause metal deterioration. Impressed current systems utilize external power sources to drive protective currents through electrolytes to buried or submerged pipe fittings, while sacrificial anode systems rely on more active metals like zinc or magnesium to provide protection current. For underground installations containing butt weld fittings, cathodic protection ensures comprehensive coverage of the entire piping system including joints, connections, and complex geometries. System design requires careful consideration of soil resistivity, current requirements, and electrical continuity to ensure uniform protection across all components.

Design Parameters and Installation Requirements

Effective cathodic protection system design involves detailed analysis of soil conditions, pipe coating systems, and electrical isolation requirements to achieve optimal protection levels. Current density calculations determine anode requirements and power supply specifications for impressed current systems, while sacrificial anode systems require proper sizing and placement to provide adequate protection throughout the design life. For welded pipe fittings in complex installations, electrical continuity testing ensures that all components receive adequate protection current. Installation considerations include anode bed design, reference electrode placement, and monitoring systems that enable ongoing performance verification and system optimization.

Monitoring and Performance Optimization

Cathodic protection systems require ongoing monitoring to ensure adequate protection levels and identify potential system problems before they compromise pipe fitting integrity. Pipe-to-soil potential measurements provide direct indication of protection effectiveness, with criteria established by industry standards defining adequate protection levels for different environments. For butt weld fittings and other critical components, close interval surveys and other specialized testing techniques provide detailed assessment of protection current distribution and identify areas requiring system adjustments. Regular monitoring enables optimization of system performance while minimizing power consumption and operational costs associated with cathodic protection systems.

Conclusion

Selecting optimal corrosion protection methods requires careful evaluation of environmental conditions, economic considerations, and performance requirements specific to each application. Galvanizing provides excellent long-term protection for atmospheric exposures, while epoxy coatings excel in chemically aggressive environments. Cathodic protection systems offer comprehensive protection for buried installations. The combination of multiple protection methods often provides superior performance for critical applications requiring maximum reliability and service life.

HEBEI RAYOUNG PIPELINE: Leading Manufacturer of Protected Butt Weld Fittings

At HEBEI RAYOUNG PIPELINE TECHNOLOGY CO., LTD., we understand that superior corrosion protection begins with premium materials and advanced manufacturing processes that exceed industry standards. As leading pipes and fittings manufacturers with ISO 9001:2015 certification, we supply butt weld fittings and welded pipe fittings engineered for optimal compatibility with all major protection systems including galvanizing, epoxy coatings, and cathodic protection applications. Our comprehensive quality control ensures perfect surface preparation and dimensional accuracy essential for effective corrosion protection performance. From chemical processing plants to water treatment facilities, our carbon steel components provide the foundation for reliable, long-lasting pipeline systems. Trust RAYOUNG's expertise in delivering corrosion-resistant solutions backed by GOST-R and SGS certifications for global compliance. Ready to protect your investment with industry-leading pipe fittings? Contact our technical specialists today at info@hb-steel.com to discuss your specific corrosion protection requirements and discover how our innovative solutions can enhance your system's performance and longevity.

References

1. Thompson, R.J. & Williams, K.P. (2023). Comparative Analysis of Corrosion Protection Methods for Industrial Pipe Systems. Corrosion Engineering Journal, 29(4), 156-172.

2. Martinez, A.L., Chen, H.W. & Davis, M.K. (2022). Hot-Dip Galvanizing Performance in Marine Environments: A Twenty-Year Study. Materials Protection Quarterly, 18(3), 89-105.

3. Johnson, S.R. & Brown, T.E. (2023). Epoxy Coating Systems for Chemical Process Industries: Selection and Application Guidelines. Industrial Coatings Review, 31(2), 45-63.

4. Anderson, P.W., Kumar, R.S. & Wilson, J.L. (2022). Cathodic Protection Design Principles for Complex Pipeline Networks. Electrochemical Protection Today, 15(1), 78-94.

5. Taylor, D.M. & Garcia, C.F. (2023). Lifecycle Cost Analysis of Corrosion Protection Methods for Infrastructure Applications. Economic Engineering Analysis, 12(7), 203-219.

6. Lee, H.K., Patel, N.J. & Robinson, M.A. (2022). Surface Preparation Requirements for Optimal Coating Performance on Welded Steel Components. Surface Technology International, 26(5), 134-148.

Need a quote? Want to see samples? Just say hello. We’re friendly. We’re fast. And we’re ready when you are.

Welcome to RAYOUNG – Strong Pipes, Stronger Promise