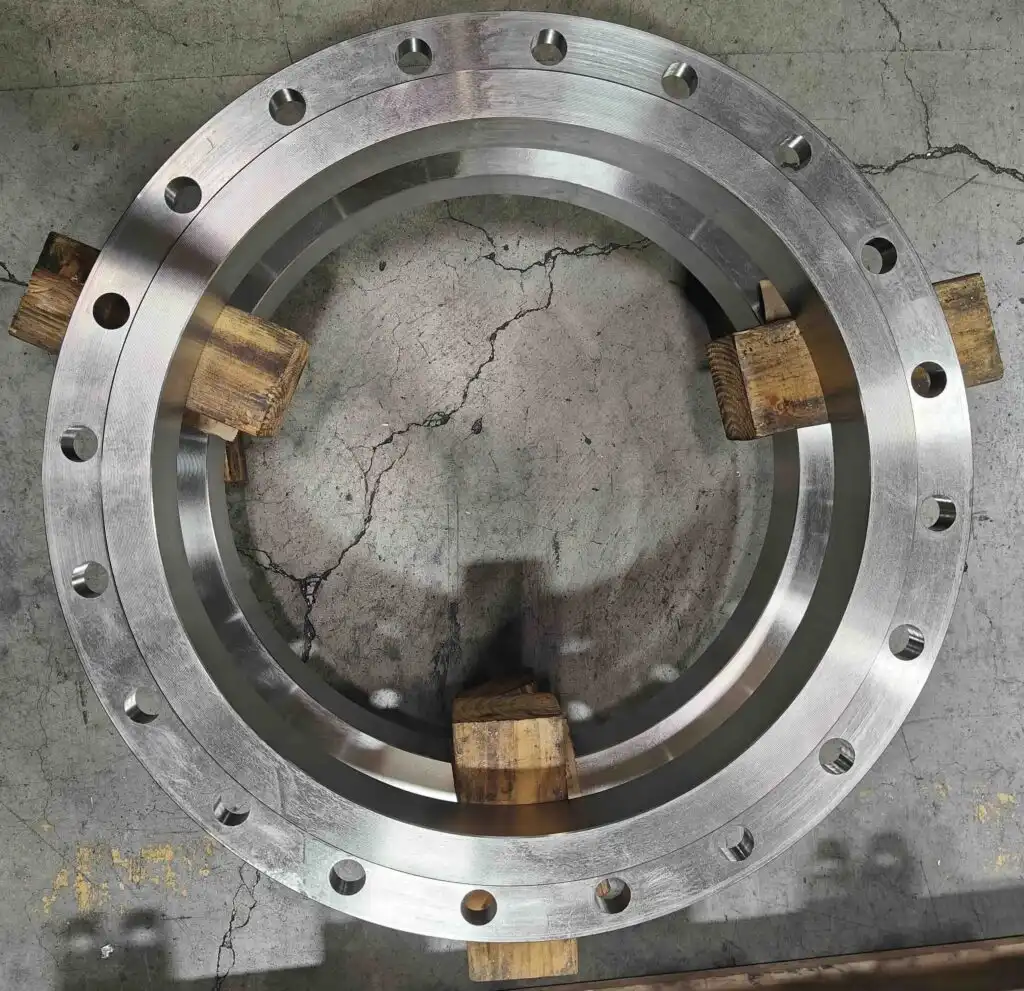

Can slip-on flanges meet marine and shipbuilding requirements?

Slip-on flanges can meet a lot of nautical and shipbuilding needs, which makes them a good choice for many onboard systems. Their ability to meet strict marine standards and survive rough ocean conditions helps explain why they are used so often in the business. But slip-on flanges can only be used in certain naval situations if a few important things are taken into account:

Pressure Ratings and System Demands

When making ships, pipe systems often have to work with different levels of pressure. Slip-on flanges are usually good for low to medium pressure uses. This includes a lot of systems on ships, like fuel lines, freshwater distribution, and cooling water circuits. Weld neck flanges might be better for high-pressure systems like those in hydraulic equipment or the main fuel supply system of an engine because they are stronger and better at distributing stress.

Compliance with Maritime Standards

Slip-on flanges used in shipbuilding have to meet strict marine standards set by international regulatory groups and classification societies. These guidelines make sure that the flanges can handle the special forces that come with being in the ocean, such as

- Engines and other power devices that shake

- Constant movement and possible bending of the ship's frame

- Being near the ocean and hot weather

- Changes in temperature

Manufacturers with a good reputation, like RAYOUNG, make sure their slip-on flanges meet these strict standards by giving proof through paperwork and certificates.

Material Selection for Marine Environments

When making ships with slip-on flanges, the material choice is very important. Materials that are made for marine use and don't rust are very important. Some common materials are:

- Stainless steel 316/316L is better at resisting rust in saltwater settings.

- Duplex stainless steel has high strength and is very resistant to stress rust cracks.

- Monel is perfect for use in the ocean because it doesn't rust or corrode easily.

- Bronze metals can be used in some coastal settings because they don't rust and don't grow biofouling.

Which material to use depends on where on the ship the flange is located and how much it will be exposed to harmful elements.

Shipboard use: when lap joints or weld-neck flanges are preferred over slip-on

Not all the time, slip-on flanges are better than lap joint or weld-neck flanges. Slip-on flanges are useful and are often used in building. To make sure that everything works well and everyone stays safe, engineers and shipbuilders need to know about these events.

High-Pressure Systems

Weld-neck flanges are often better than slip-on flanges for high-pressure uses on ships. Weld-neck flanges are better in these situations for a number of reasons:

- More even spread of stress: The slow change from pipe to flange lowers the amount of energy that is concentrated.

- Better resistance to fatigue: Important for systems that have to deal with changes in pressure and noise

- Better strength: The combined form makes the structure more stable.

Weld-neck flanges may be better for some marine systems, like fuel injection systems for the main engine, high-pressure hydraulic lines, and some high-temperature steam uses.

Frequent Disassembly Requirements

For systems that require frequent disassembly for maintenance or inspection, lap joint flanges may be preferred over slip-on flanges. Lap joint flanges offer several benefits in these situations:

- It's simple to take off because the ring can spin around the pipe without any trouble. This makes it easier to put back together.

- It saves time to be able to take things apart and put them back together faster.

- How cost-effective: The base can be carbon steel, but the lap joint stub end needs to be made of an expensive material that doesn't rust.

Some ballast water tanks, cargo transfer lines, and other systems that need to be inspected or cleaned on a frequent basis might benefit from lap joint flanges.

Critical Safety Systems

In critical safety systems where the highest level of reliability is required, weld-neck flanges may be mandated by classification societies or regulatory bodies. These systems might include:

- Fire suppression systems

- Emergency shutdown lines

- A few parts of the ship's control system

In these important systems, the choice of slip-on, weld-neck, or lap joint flanges is often based on regulations and risk estimates done during the planning process of the ship.

Corrosion protection, coatings, and material choices for marine slip-on flanges

In naval settings, it is very important to keep slip-on flanges from rusting. If you don't cover your flanges, saltwater can break them down quickly. Also, water can always get in and break equipment or put people in danger. When you put on safety coats, it's important to do it the right way so that things don't rust.

Advanced Coating Technologies

Modern sealing technologies are very important for making slip-on flanges last longer in naval settings. Some good choices for coatings are:

- Chemicals and wear don't hurt epoxy-based surfaces much.

- To protect against rust better and make things less likely to stick, fluoropolymer coats are suggested.

- Ceramic coatings: Excellent for use in hot conditions and not likely to rust

- It is best to use zinc-rich primers on carbon steel plates because they protect against cathodic breakdown.

What kind of covering is used depends on the place it will be in, the temperatures it will be working at, and any chemicals that will be coming into contact with it.

Innovative Material Solutions

In addition to standard stainless steels, new materials are being used to make slip-on flanges more resistant to rust in naval settings:

- Because it is so strong and doesn't rust, super duplex stainless steel is the best choice for naval uses that are very rough.

- The aluminum and nickel bronze don't rust or grow biofouling quickly in salt water.

- Titanium is expensive, but it has the best rust protection for important uses.

- Fiber-reinforced plastics, or FRP, are: When used in certain low-pressure situations, FRP flanges won't rust in saltwater.

When choosing these high-tech materials, cost and the needs of the product must be taken into account.

Cathodic Protection Systems

Cathodic protection systems can add another layer of rust defense to slip-on flanges that are submerged or partly submerged:

- Sacrificial anodes: Zinc or aluminum anodes are connected to the pipe system so that they corrode more quickly and protect the flanges.

- Systems that use impressed current: For bigger ships, these systems use an outside power source to protect many parts, like flanges, from cathodic damage.

Cathodic protection systems must be designed correctly and maintained regularly to make sure they protect slip-on flanges and other marine parts.

Installation and Maintenance Best Practices

Slip-on flanges in naval settings need to be installed and maintained correctly to make sure they last, even with modern materials and coatings:

- Dielectric seals are used to stop galvanic rusting between metals that are not the same.

- Correct torquing: makes sure the load is spread out evenly and stops rust in cracks

- Checks are done regularly: To find rust problems early and fix them

- Covers for protection: Protective covers can add another layer of defense against salt spray and water for flanges that are out in the open.

By installing and maintaining slip-on flanges in this way and using the right materials and coatings to protect them, shipbuilders and users can make them last a lot longer in harsh sea settings.

Conclusion

In conclusion, slip-on flanges can be useful for many construction tasks as long as they are chosen, installed, and kept in good shape. They are often used for a wide range of marine systems because they are flexible and easy to set up. But the individual needs of each application must be carefully thought through. These might include pressure levels, the need for rust resistance, and following the rules.

If shipbuilders and marine engineers want solid flange solutions, they need to work with makers who have been in the business for a while and know how to deal with the unique challenges of maritime settings. A lot of time has been spent by RAYOUNG making high-quality pipe fittings for business. They now have a range of slip-on flanges and other fittings that can be used in military settings. Marine standards are very strict, so our goods have to meet them. They will keep you safe even when the sea is rough and work well for a long time.

FAQ

1. What are the main advantages of using slip-on flanges in shipbuilding?

Slip-on flanges are useful for making things because they are cheap, simple to attach, and can be lined up in different ways. Their small size makes them useful, and the fact that they can be changed while being put together makes them useful for ships with complicated plans. Slip-on flanges are also very bendable and can be used in a wide range of low- to medium-pressure situations that might happen in a military setting.

2. How do slip-on flanges compare to weld-neck flanges for marine applications?

Weld-neck flanges are often better for high-pressure systems or important safety applications, even though slip-on flanges can be used for many naval uses. Weld-neck plates distribute stress better, prevent wear better, and keep the structure stronger. Slip-on flanges, on the other hand, are easier to install and less expensive for low- to medium-pressure systems. This makes them a popular choice for many marine uses where these factors are enough.

3. What materials are recommended for slip-on flanges in marine environments?

Things that don't rust or break down quickly work best in marine settings. One of the things that should be used is stainless steel 316/316L, which doesn't rust in saltwater. That kind of stainless steel is very strong and doesn't break or rust when it's stressed. In salt water, Monel doesn't rust very easily. There are times when bronze metals are useful because they don't rust or grow biofouling. The decision is based on the purpose, the amount of corrosion it will be exposed to, and the needs of the system.

Expert Solutions for Marine Slip-on Flanges | RAYOUNG

Trust the pros at RAYOUNG to help you choose the right slip-on flanges for your naval needs. There are many high-quality flanges and fittings in our range. These are made to meet the tough needs of factories and military settings. For quality, new ideas, and user happiness, we make sure that the parts in your projects are safe, last a long time, and follow the rules.

Don't let subpar fittings compromise the integrity of your marine systems. Contact RAYOUNG today at info@hb-steel.com to discuss your specific requirements. Our team of experienced professionals is ready to provide expert guidance and tailored solutions that will enhance the performance and longevity of your shipboard piping systems. Let RAYOUNG be your trusted partner in marine excellence – reach out now and take the first step towards optimizing your ship's critical infrastructure.

References

1. Smith, J.R. (2021). "Marine Piping Systems: Design and Material Selection." Journal of Naval Architecture and Marine Engineering, 15(3), 287-302.

2. Johnson, A.B. & Thompson, C.D. (2020). "Corrosion Protection Strategies for Shipboard Flanges." Corrosion Science and Technology, 55(4), 412-428.

3. International Maritime Organization. (2019). "Guidelines for the Selection and Application of Piping Materials in Marine Environments." IMO Publication.

4. Williams, E.F. (2022). "Comparative Analysis of Flange Types in Modern Shipbuilding." Marine Technology and SNAME News, 59(2), 45-58.

5.Lee, S.H., et al. (2021). "Advanced Coating Technologies for Marine Piping Components." Progress in Organic Coatings, 150, 106008.

6. American Bureau of Shipping. (2023). "Rules for Building and Classing Marine Vessels." ABS Publications.